- Joined

- Jan 10, 2015

- Messages

- 196

Once upon a time, there were affordable (ok, cheap) Broncos out there. No, really. Lemme 'splain:

Back in mid-2001, eBay used to have a section where people posted "parts/salvage" vehicles. My day job at the time was a resident tech contractor at a US Goverment installation, where I basically babysat equipment for 8 hours a day, was onsite in case something broke, so downtime would be minimal. Either I was good at my job, (or just lucky), because it meant I had a lot of time to browse the internet (which was a bit different back then). Anyway, I came across a listing for a '70 Bronco parts truck, that was sitting out in a farmer's field being used as target practice by his kids, and rusting away. It had no top, no interior, no engine - but it was cheap. I put a bid for $305 just for grins and forgot about it - until a few days later, when I found out I had won the auction.

So, the second weekend of September, my brother and I headed out from Austin in my Jeep XJ, picked up a Uhaul trailer in Amarillo, loaded up the Bronco in Oklahoma, and drug it back home. Fun trip - cold front, rain, wind, truck ruts that had the trailer weaving all over the road, etc. Got back home, returned the Uhaul on Monday - and the next day was Tuesday, September 11th, 2001. Yes, 9/11.

Anyway, this is what I started with:

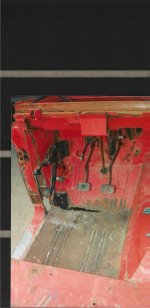

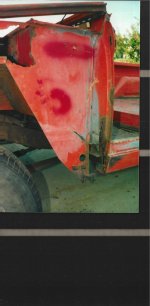

Rusted floorboards, door posts, inner fenders, bent core support...but the frame was straight, and it did have a hood, grille, doors, and tailgate.

At the time, my project vehicle funds were pretty scarce, and I really just wanted a trail truck to go wheeling. I figured I'd slap together a junkyard engine, weld some patch panels over the worst rust, do a few repairs, and go have fun. Remember, old Broncos were just...old Broncos back then - not collectible classics. So, I got to work.

Rebuilt a 351W and dropped it in, straightened out some bent sheetmetal, sprayed some primer:

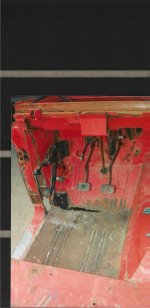

Modified the dash, swapped in a ZF 5 speed, fabricated twin stick shifters for the original Dana 20 T-case, cut and bent some sheetmetal floorpans and welded in them in:

Rolled on bedliner (which didn't last):

Found a Dana 60 full floating rear axle, rebuilt it, and fabricated custom brackets to mount GM 12" disk brakes:

Over the years, I moved out to the country, had a little money to work with, so I built a shop, and made some changes to the Bronco as the project stretched out...and out. The original plan to just make it a trail truck turned into more of a full restomod buildup, so I decided to strip it down to the frame and start over.

Made a few changes to the frame - removed factory shock mounts, added shock hoops front and rear, had it sandblasted and powdercoated, new suspension (4" lift), full-width high pinion Dana 44 from a '78 Bronco, longer radius arms, relocated arm mounts, etc.

Back in mid-2001, eBay used to have a section where people posted "parts/salvage" vehicles. My day job at the time was a resident tech contractor at a US Goverment installation, where I basically babysat equipment for 8 hours a day, was onsite in case something broke, so downtime would be minimal. Either I was good at my job, (or just lucky), because it meant I had a lot of time to browse the internet (which was a bit different back then). Anyway, I came across a listing for a '70 Bronco parts truck, that was sitting out in a farmer's field being used as target practice by his kids, and rusting away. It had no top, no interior, no engine - but it was cheap. I put a bid for $305 just for grins and forgot about it - until a few days later, when I found out I had won the auction.

So, the second weekend of September, my brother and I headed out from Austin in my Jeep XJ, picked up a Uhaul trailer in Amarillo, loaded up the Bronco in Oklahoma, and drug it back home. Fun trip - cold front, rain, wind, truck ruts that had the trailer weaving all over the road, etc. Got back home, returned the Uhaul on Monday - and the next day was Tuesday, September 11th, 2001. Yes, 9/11.

Anyway, this is what I started with:

Rusted floorboards, door posts, inner fenders, bent core support...but the frame was straight, and it did have a hood, grille, doors, and tailgate.

At the time, my project vehicle funds were pretty scarce, and I really just wanted a trail truck to go wheeling. I figured I'd slap together a junkyard engine, weld some patch panels over the worst rust, do a few repairs, and go have fun. Remember, old Broncos were just...old Broncos back then - not collectible classics. So, I got to work.

Rebuilt a 351W and dropped it in, straightened out some bent sheetmetal, sprayed some primer:

Modified the dash, swapped in a ZF 5 speed, fabricated twin stick shifters for the original Dana 20 T-case, cut and bent some sheetmetal floorpans and welded in them in:

Rolled on bedliner (which didn't last):

Found a Dana 60 full floating rear axle, rebuilt it, and fabricated custom brackets to mount GM 12" disk brakes:

Over the years, I moved out to the country, had a little money to work with, so I built a shop, and made some changes to the Bronco as the project stretched out...and out. The original plan to just make it a trail truck turned into more of a full restomod buildup, so I decided to strip it down to the frame and start over.

Made a few changes to the frame - removed factory shock mounts, added shock hoops front and rear, had it sandblasted and powdercoated, new suspension (4" lift), full-width high pinion Dana 44 from a '78 Bronco, longer radius arms, relocated arm mounts, etc.

Attachments

Last edited: