Well, today.... Ok, let me back up...

Many moons ago, I was trying to flush the coolant system. It seems that my engine had stop leak put in it at some point before I got it, and I wanted the system clean. So I had the engine warm, and thought I had the pressure off the system, and pulled the upper clamp off the radiator, which lead to brownish red coloring all over EVERYTHING in the shop, including the sheet rock in the ceiling, AND across part of my belly ending in time at the ER...which sucked because they didn't do anything that I hadn't already done at home...except give me a shot for pain meds.

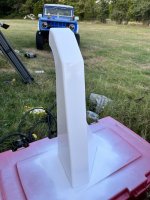

Fast forward to more modern days...like today. This engine and under the hood are STILL coated in that coloring. But today I spent some time doing a proper flush. As in two cycles with two bottles of flush. Reving the engine up and down, letting it idle, raising the idle... I got it pretty clean inside from what I could see.

So now I've got that color all over just about everything because of the way I had stuff splashing. So I decided to get some Zep industrial strength cleaner and spray all over under the hood, and then power wash it off. Simple, right? Now I've got three plug wires throwing spark between the valve cover on one side and the alternator cover on the other. So tomorrow morning, I get to put new plugs on it before loading it up for OCBR. And I MIGHT have time to get the rear bumper mounted. But I have the top rear 1" of the frame rail to replace so I have something to bolt to, so it's not really simple. Just not a full weekend of work. I had to cut that part off due to the previous owner having a piece of 4x6x3/8 angle iron welded on for a bumper.

Fun times. If you're read this entire, worthless post, give it a like to say that you had nothing better to do!