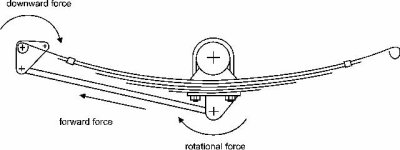

It seems like the root of axle wrap problems starts at the leaf springs, perch's, and U bolts. A little bit from several places add's up to a larger issue....

Of course this whole issue of axle wrap was never an issues with stock size tires, stock engines, and stock gears. Drop in a stout engine making big HP, low gears and big tires and now the pinion gear wants to climb the ring gear and twist the axle housing.

The stock leaf spring perch's are scrawny and don't provide much surface area for mounting of the leaf pack. The stock U bolts are too small for the new style leaf packs, plus when using a suspension lift now the pinion angle is bum feeding the driveshaft.

Several things needs addressed to fully correct these issues. Ruff stuff

http://www.ruffstuffspecialties.com/catalog/R1991.html and other mfg's make some dandy leaf perch's that are larger than stock. Simply cut the old ones off and weld the new ones in place - at the correct "tip up" angle to fix the driveshaft alligment issue. Shims are another form of band aid, no need to use shims if you make the correction when welding on the new perch's.

I consulted with knowledgable folks at Tom Woods driveshafts

http://www.4xshaft.com/ when doing mine. These guys are super helpful....like the same level of customer service you get from Duff's or WH.

WH makes some really nice U bolts and top plates

http://www.wildhorses4x4.com/product/Extreme_duty_U_bolt_kit http://www.ruffstuffspecialties.com/catalog/R1991.html , that actually fit correctly and allow you to snug-down the leaf pack to the perch.

1) Having large spring perch's -welded on at the correct angle, and 2) U bolts that you can really tighten to the proper tourque and keep tight is the answer.

^....These two steps alone will "fix" nearly all of the excessive axle wrap.

These first two steps *need* done before you start adding band-aids like anti-wrap bars.

I'm also using the WH wrap bar on mine

http://www.wildhorses4x4.com/product/Wrap_Trap. Seems pretty straightforward to install. Lay the mount acorss the frame and then mock-up the mount that welds to the rear housing with the Bronco sitting on its own weight. Then clamp/tack it in place, using a floor jack -compress and release the suspension through it full range to travel by jacking it up and letting it down while observing and looking for anything binding or not riding properly...weld the mounts in place solid.

EDIT: Pic 4 shows the final, if you look closely at pic 5-8 you'll see shims under the leaf pack. I had to do everything three or four times, I'm a slow learner. After several attempts to make it "right" I ended up using the large spring perch's and correcting the pinion angle at the same time, large U bolts. The wrap trap was icing on the cake to keep the diff housing from twisting in anstipation of a strong engine and big tires.

In this pic you can see the upper wrap mount layed accross the frame and the distance I'm holding the rear mount above the housing is about the amount of travel my rear housing goes up & down -showing the importance of mounting it when its sitting on its own weight.

The wrap-trap bar doesn't align with the bushing unless and until its sitting on it won weight!

Lining up the mount is simple w/o exhaust

Here's a shot of the rear wrap-trap mount welded to the axle housing before the spring perch's were done