- Joined

- Apr 3, 2022

- Messages

- 670

I know others have done this but wanted to share my experience. I’ve restored several other vintage clusters but not a bronco one. This one is by far the easiest to restore…hands down. Anyone with patience can do it no problem. Here are my impressions:

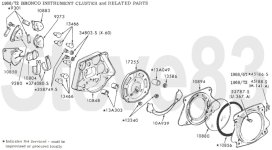

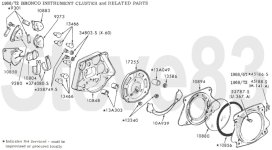

1. Start by taking several pictures of front and back and continue to take pictures as you take it apart.

2. Disassembly is straight forward. Mainly just unscrewing the parts. First, I removed all the gauges by taking out the screws that hold them in on the back. Set them aside for now but be very careful not breaking the needles.

3. Remove the backing plate. It unscrews.

You should now be down to the face where the speedo needle is. Again, be careful of the needle. Carefully pop off the needle. A little gentle pull here and there around the base of the needle and it will pop off.

4. Now that the needle is off, you will see three small rivets that hold on the speedo mechanism. Use a small drill bit and drill out the back of the rivets. Drill it out enough that the rivet pops away from the plate. Don’t pry the rivet apart you might damage the face plate.

5. You can now work on the speedo gearing. You can remove the odometer barrel by taking off the small clip on one end of it. If desired, you can set the odometer to zero if doing a full restoration and your odometer is exempt in your state. Reinstall the odometer with the small tangs over the lip of the case (look at how those tangs go before you remove barrel…should be in a picture as well).

6. Put a very small amount of lithium grease on the white plastic gears and a small drop of oil in between each of the odometer barrel rings. Unless something is broken, your Speedo mechanism should be good to go. Set it aside.

7. Moving to the face plate, you can restore it by polishing or buying stickers. Mine looked fine other than the very center aluminum was pitted. I carefully sanded it with 320, then 600, then 1000, then polisher. This takes the most time but go slow and be careful not to sand in the mph tick marks or you will be forced to by the sticker kit. One you are satisfied with the face plate cleanup, set it aside.

8. Test every gauge. Start by testing the volt reg. The male spade is power in and the female is the reduced power out. Use a simple 9 volt battery and some alligator clips. Test the output. If using a digital tester, it will pulse around but the high average should be somewhere between 5 and 7 give or take. If it’s good, move to gauges. If it’s not you will need to replace it before testing gauges. Toms has new ones for about $25. YOU CANNOT HOOK UP 12 volts TO THE GAUGES OR THEY WILL FRY. This is what the regulator is for…it reduces the 12volts in to a lower 5-7 volts.

9. Using the 9 volt battery connected to the power in on the regulator, connect the power out to the power in on the gauge. Look back at your picture of the wires going to the unit and ensure you are connecting to the gauge power in and not the ground terminal. The black with white tracer is the reduced power to gauge. Connect the other terminal to the ground on the 9v battery. All the gauges should max out when connected to the volt reg. This tells you that at least they are working. If any of the three gauges (Oil, Temp, Fuel) do not max out when connected directly to the VR, the gauge is bad. You can also check the Ohms at each gauge between the terminals on the back. They should be between 8 and 15…closer to 15 is better).

10. To check the accuracy of each gauge, you need some various “resisters.” I bought several of the larger resisters years ago just to be able to test gauges like this. Good investment and they only cost a few dollars each…I’d say you can get all the resistors you need for under 20 bucks. All you do is place a resistor in the ground line. What you are doing is forcing a resistance in the line that reduces the ground flow and results in a decreased needle movement. Resistance runs in a series so if you have a 25 Ohm resistor and a 5 ohm resistor, you can connect them end for end in line to the ground source and it will equal 30 ohms. So if you purchase several resisters, just get a wide assortment so you can dial in pretty much any ohm you require. You can also use a fuel sending unit as an ohms tool. It works on any of the resistance gauges...just determine what the full and empty points are in terms of ohms and you can even mark a scale on the arm base that gives you different levels of resistance between full up and full down. Here are the resisters ohms for each gauge:

Oil

90 psi = 10 ohms

70 = 20

40 = 30

Temp

120’ = 73 ohms

195’ = 20

230’ = 10

Fuel

Empty = 73 ohms

¼ = 33

½ =25

¾ = 20

Full = 10

These are all plus or minus a few Ohms but should result in a reading plus or minus the width of the needle.

11. I also used a flat black paint to paint the secondary backing plate. (it’s the one that has a chrome ring in the center and everything else is flat black). I used Testors fluorescent paint to repaint all the needles. I also used colored filter gel screen to replace the faded out blinker and hi-beam color screens (all links below). If you haven’t already, clean, sand, and paint the outside case that shows on the dash. Any color you want. Clean the glass.

12. Place the speedo gauge on the faceplate aligned with where the little rivets were. I used tiny screws and nuts to reattach the plate. They are not seen anyway, but an easy and cheap way to reattach firmly. Put it all back together. Last, install the gauges back into their places.

None of my mechanisms or gauges were bad so total resto cost was under 30 bucks. (I already had the resisters.) I'm still waiting on some paint to fully dry before final assembly. I'll post finished pics later.

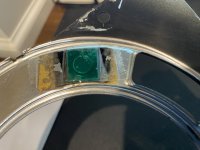

View attachment 892020

View attachment 892016

View attachment 892020

View attachment 892016

1. Start by taking several pictures of front and back and continue to take pictures as you take it apart.

2. Disassembly is straight forward. Mainly just unscrewing the parts. First, I removed all the gauges by taking out the screws that hold them in on the back. Set them aside for now but be very careful not breaking the needles.

3. Remove the backing plate. It unscrews.

You should now be down to the face where the speedo needle is. Again, be careful of the needle. Carefully pop off the needle. A little gentle pull here and there around the base of the needle and it will pop off.

4. Now that the needle is off, you will see three small rivets that hold on the speedo mechanism. Use a small drill bit and drill out the back of the rivets. Drill it out enough that the rivet pops away from the plate. Don’t pry the rivet apart you might damage the face plate.

5. You can now work on the speedo gearing. You can remove the odometer barrel by taking off the small clip on one end of it. If desired, you can set the odometer to zero if doing a full restoration and your odometer is exempt in your state. Reinstall the odometer with the small tangs over the lip of the case (look at how those tangs go before you remove barrel…should be in a picture as well).

6. Put a very small amount of lithium grease on the white plastic gears and a small drop of oil in between each of the odometer barrel rings. Unless something is broken, your Speedo mechanism should be good to go. Set it aside.

7. Moving to the face plate, you can restore it by polishing or buying stickers. Mine looked fine other than the very center aluminum was pitted. I carefully sanded it with 320, then 600, then 1000, then polisher. This takes the most time but go slow and be careful not to sand in the mph tick marks or you will be forced to by the sticker kit. One you are satisfied with the face plate cleanup, set it aside.

8. Test every gauge. Start by testing the volt reg. The male spade is power in and the female is the reduced power out. Use a simple 9 volt battery and some alligator clips. Test the output. If using a digital tester, it will pulse around but the high average should be somewhere between 5 and 7 give or take. If it’s good, move to gauges. If it’s not you will need to replace it before testing gauges. Toms has new ones for about $25. YOU CANNOT HOOK UP 12 volts TO THE GAUGES OR THEY WILL FRY. This is what the regulator is for…it reduces the 12volts in to a lower 5-7 volts.

9. Using the 9 volt battery connected to the power in on the regulator, connect the power out to the power in on the gauge. Look back at your picture of the wires going to the unit and ensure you are connecting to the gauge power in and not the ground terminal. The black with white tracer is the reduced power to gauge. Connect the other terminal to the ground on the 9v battery. All the gauges should max out when connected to the volt reg. This tells you that at least they are working. If any of the three gauges (Oil, Temp, Fuel) do not max out when connected directly to the VR, the gauge is bad. You can also check the Ohms at each gauge between the terminals on the back. They should be between 8 and 15…closer to 15 is better).

10. To check the accuracy of each gauge, you need some various “resisters.” I bought several of the larger resisters years ago just to be able to test gauges like this. Good investment and they only cost a few dollars each…I’d say you can get all the resistors you need for under 20 bucks. All you do is place a resistor in the ground line. What you are doing is forcing a resistance in the line that reduces the ground flow and results in a decreased needle movement. Resistance runs in a series so if you have a 25 Ohm resistor and a 5 ohm resistor, you can connect them end for end in line to the ground source and it will equal 30 ohms. So if you purchase several resisters, just get a wide assortment so you can dial in pretty much any ohm you require. You can also use a fuel sending unit as an ohms tool. It works on any of the resistance gauges...just determine what the full and empty points are in terms of ohms and you can even mark a scale on the arm base that gives you different levels of resistance between full up and full down. Here are the resisters ohms for each gauge:

Oil

90 psi = 10 ohms

70 = 20

40 = 30

Temp

120’ = 73 ohms

195’ = 20

230’ = 10

Fuel

Empty = 73 ohms

¼ = 33

½ =25

¾ = 20

Full = 10

These are all plus or minus a few Ohms but should result in a reading plus or minus the width of the needle.

11. I also used a flat black paint to paint the secondary backing plate. (it’s the one that has a chrome ring in the center and everything else is flat black). I used Testors fluorescent paint to repaint all the needles. I also used colored filter gel screen to replace the faded out blinker and hi-beam color screens (all links below). If you haven’t already, clean, sand, and paint the outside case that shows on the dash. Any color you want. Clean the glass.

12. Place the speedo gauge on the faceplate aligned with where the little rivets were. I used tiny screws and nuts to reattach the plate. They are not seen anyway, but an easy and cheap way to reattach firmly. Put it all back together. Last, install the gauges back into their places.

None of my mechanisms or gauges were bad so total resto cost was under 30 bucks. (I already had the resisters.) I'm still waiting on some paint to fully dry before final assembly. I'll post finished pics later.

View attachment 892020

View attachment 892016

View attachment 892020

View attachment 892016

Last edited: