JSmall

Bronco Guru

- Joined

- Feb 18, 2004

- Messages

- 3,224

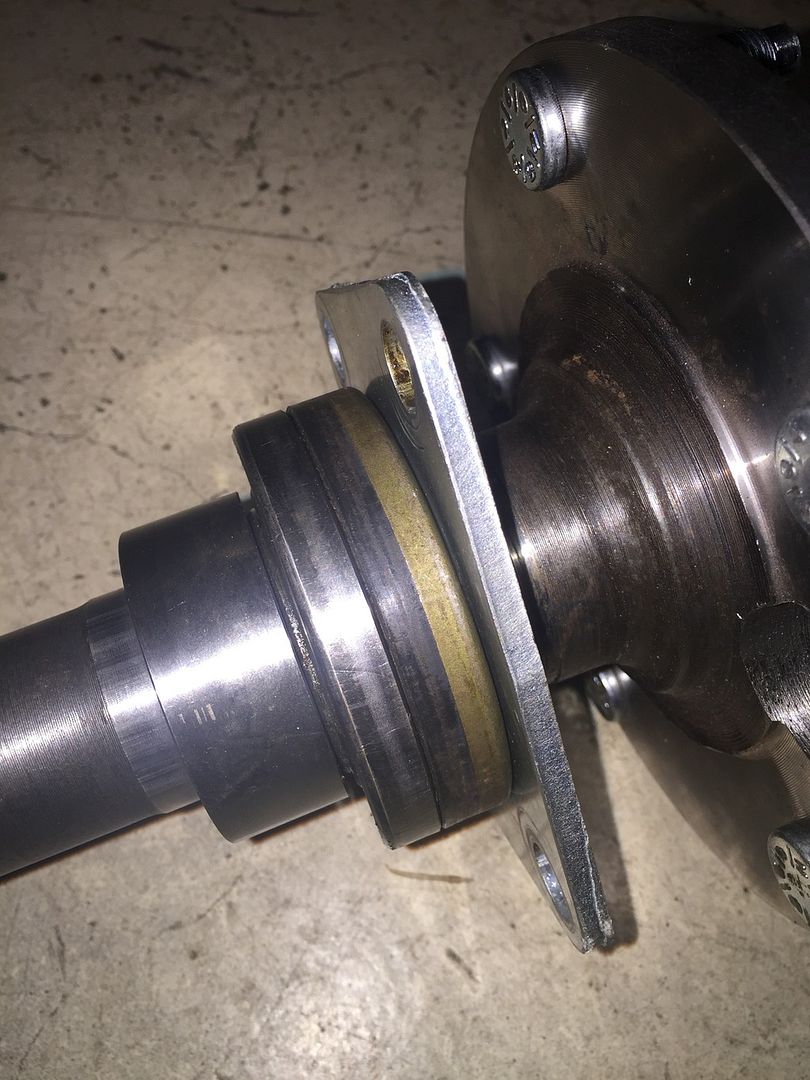

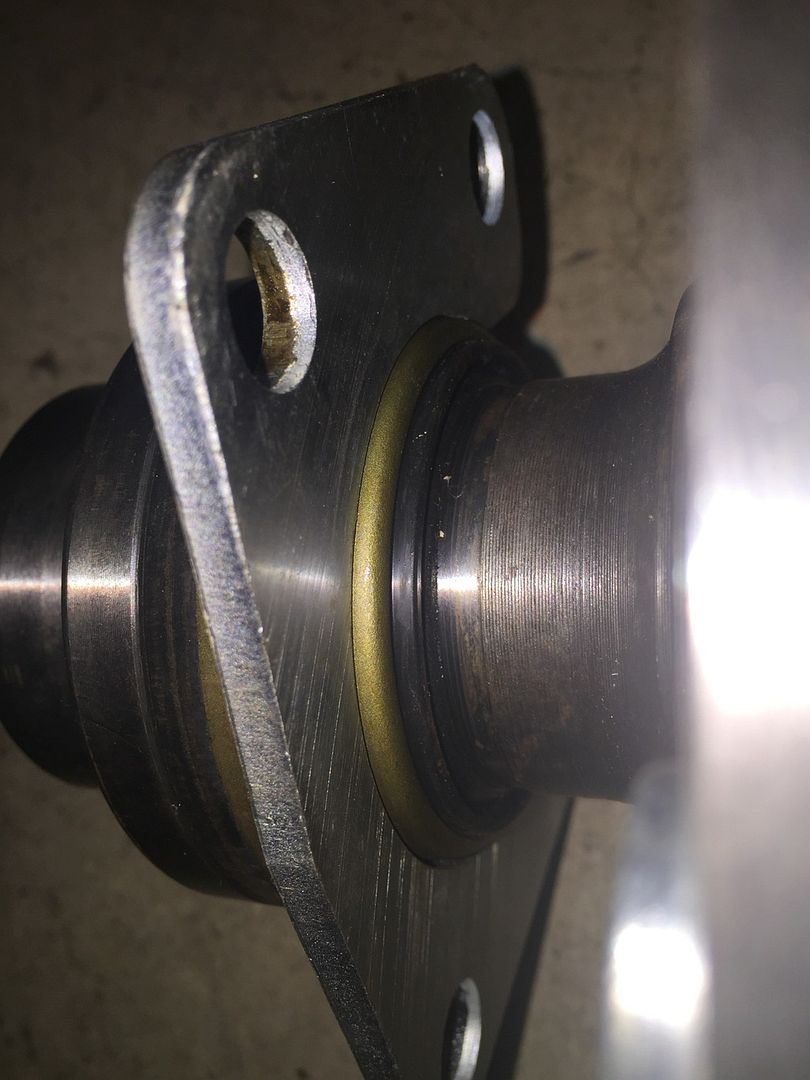

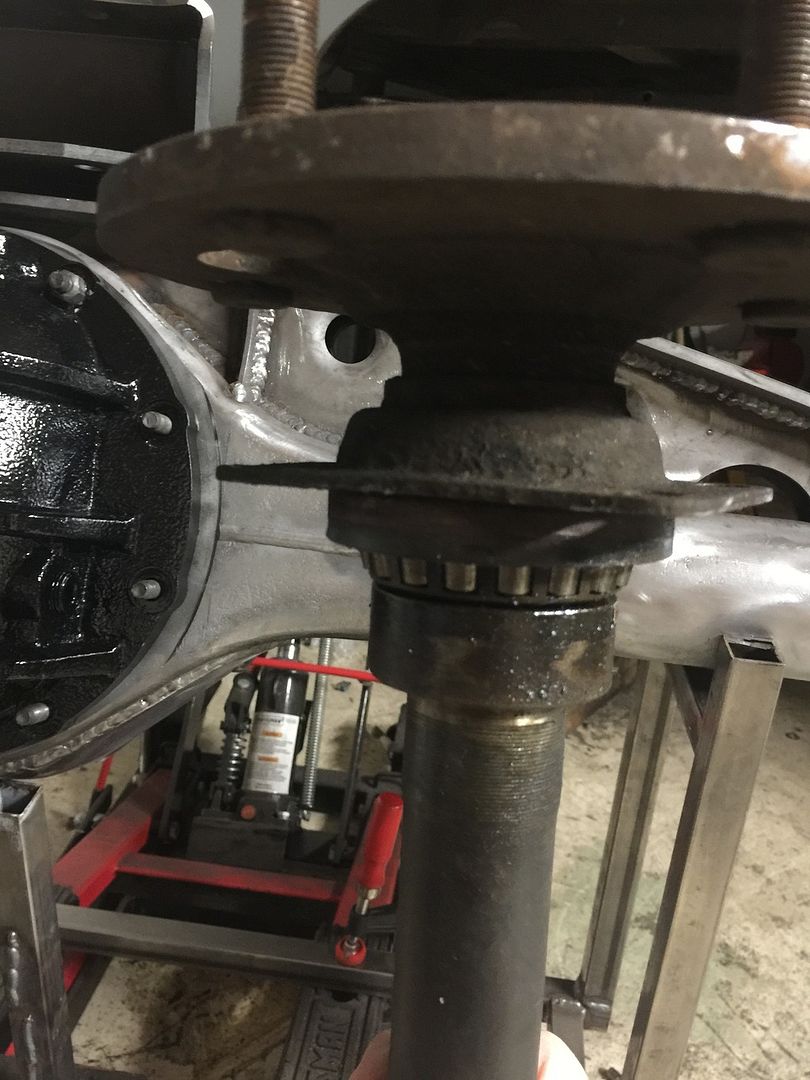

Looking for some advice. The bearing is seated in the housing end and I still have this gap. What could be causing this and how do I go about fixing it?

Full width 9"

35 spline Yukon shafts

Set20 bearings

Yukon bearing retainers

Drum backing plate cut for spacer

I know the shaft isn't bottoming out on the ARB cross pin. I also know the bearing race is seated all the way into the housing. Is it possible that I have the wrong bearing retainers? Is it okay to suck everything down and not worry about the gap?

Full width 9"

35 spline Yukon shafts

Set20 bearings

Yukon bearing retainers

Drum backing plate cut for spacer

I know the shaft isn't bottoming out on the ARB cross pin. I also know the bearing race is seated all the way into the housing. Is it possible that I have the wrong bearing retainers? Is it okay to suck everything down and not worry about the gap?