Community

Buy / Sell

Bronco Tech

3 Arm Wiper Setup

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

-

Welcome to ClassicBroncos! - You are currently viewing the forums as a GUEST. To take advantage of all the site features, please take a moment to register. It's fast, simple and absolutely free. So please join our community today!If you have problems registering or can't log into your account, please contact Admin.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

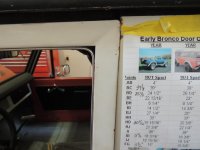

Driver door Post replacement... Questions

- Thread starter 904Bronco

- Start date

Heading out to do a parts run... Be back in an hour or so.

Your seeing a lot with just pictures...

I know I am close to getting where it needs to be.

Your seeing a lot with just pictures...

I know I am close to getting where it needs to be.

If you remove the upper shim it will pull the window frame away from the hard top.

There were washer shims before I took things apart and replaced the post.

Currently, I reassembled everything without them... So there is nothing to remove.

Sorry if I was confusing...

- Joined

- Oct 13, 2007

- Messages

- 2,716

Add a shim to just the bottom and see if it will raise the body line a hair. It may move that window frame forward also. Then I would loosen all the bolts on the driver side top and move it back .125".

I still vote the post is super close and where it needs to be welded.

I still vote the post is super close and where it needs to be welded.

- Joined

- Oct 13, 2007

- Messages

- 2,716

I have adjusted a door like that up before with just a floor jack and the door almost closed. Then over raise it a few times till it settles right. But that is plan C.

Add a shim to just the bottom and see if it will raise the body line a hair. It may move that window frame forward also. Then I would loosen all the bolts on the driver side top and move it back .125".

I still vote the post is super close and where it needs to be welded.

I have reached the point where I think I will weld it in...

I will check for the hardtop movement back 1st...

There is very little movement of the post. Most of my screws are loose from all the jiggling with the door. The door post is positioned very close to the previous numbers I took and the numbers from the sheet...

I am slowly driving myself mad try to manipulate everything to get it just so... By myself...But so far no lost sleep or door nightmares!

But my knees are starting to complain...

That is how the factory final fits the closure panels. The classification was called Door Fitter. Bend them to fit. Little at a time though. Ken

- Joined

- Jul 4, 2016

- Messages

- 791

You are inspiring others! Keep at it. My driver door gets stuck closed after I open it. Very frustrating.

Sent from my SAMSUNG-SM-G930A using Tapatalk

Sent from my SAMSUNG-SM-G930A using Tapatalk

- Joined

- Oct 13, 2007

- Messages

- 2,716

I think your first try fit is the best I have seen.

The Deed is done...

95% welded in, a few more welds to do and finish up the front upper corner of the post.

The top is all the way forward, so there is room to slide it back.

I took the door off, rechecked the measurements, made an adjustment at the top and started welding.

Tomorrow I will hang the door and hope that I am where I need to be!

95% welded in, a few more welds to do and finish up the front upper corner of the post.

The top is all the way forward, so there is room to slide it back.

I took the door off, rechecked the measurements, made an adjustment at the top and started welding.

Tomorrow I will hang the door and hope that I am where I need to be!

Attachments

- Joined

- Oct 13, 2007

- Messages

- 2,716

I have found the door fits better once welded compared to just screws due to more rigidity.

So for those of you that are wondering...

I hung the door and fender today and then had to step away to watch my son play JV baseball.

Yes welding the door post in makes it much more rigid and takes a lot of play out of it. Confidence? Blind faith maybe to just go ahead... Or good direction from rjrobin2001 ;D

I went back at it after dinner and everything was very close. I just could not get the upper hinge to come out far enough to match the fender?

So here is something to write down: The plate inside the door post is different from the factory plate. The two outer holes are farther inboard. So I had to support the door, take the upper hinge off, move the plate as far inboard as I could and then take a carbide bit through the hinge bolt holes to trim it. I wish that I had looked at that closer before welding. And it took sometime.

1st picture - shows the post door clearance from the A-pillar. Before it was making contact.

2nd picture - This is how much the hinge had to move outboard. See marker pen marks...

After I got the door to slide out everything just sort of fell into place.

I had to adjust the striker/Nader pin. Clean the the paint off it, run a tap through the threads, reassemble with anti seize.

Make adjustment, lube, readjust...

There still was a little binding, so I put the two stainless washer shims that were there before on the outer bolts. And the binding stopped Guessing the Hinges are not quite right.

Guessing the Hinges are not quite right.

The Hardtop still needs to move back 1/8" on the drivers side, but the upper door is not making contact. The bolts are out of the top, but I think the old gasket is holding it?

So the next step is to finish welding a number of spots, grind smooth, take the door and fender back off, Primer and some rattle can paint, seam seal, then rehang the door.

Then I have to fix the inner fender dent, remove 7 spot welds, flatten panels, remove the PO's pop rivets, every other one > plug weld back together.

Been an interesting ride so far. Thanks for your help Folks.

*

I hung the door and fender today and then had to step away to watch my son play JV baseball.

Yes welding the door post in makes it much more rigid and takes a lot of play out of it. Confidence? Blind faith maybe to just go ahead... Or good direction from rjrobin2001 ;D

I went back at it after dinner and everything was very close. I just could not get the upper hinge to come out far enough to match the fender?

So here is something to write down: The plate inside the door post is different from the factory plate. The two outer holes are farther inboard. So I had to support the door, take the upper hinge off, move the plate as far inboard as I could and then take a carbide bit through the hinge bolt holes to trim it. I wish that I had looked at that closer before welding. And it took sometime.

1st picture - shows the post door clearance from the A-pillar. Before it was making contact.

2nd picture - This is how much the hinge had to move outboard. See marker pen marks...

After I got the door to slide out everything just sort of fell into place.

I had to adjust the striker/Nader pin. Clean the the paint off it, run a tap through the threads, reassemble with anti seize.

Make adjustment, lube, readjust...

There still was a little binding, so I put the two stainless washer shims that were there before on the outer bolts. And the binding stopped

The Hardtop still needs to move back 1/8" on the drivers side, but the upper door is not making contact. The bolts are out of the top, but I think the old gasket is holding it?

So the next step is to finish welding a number of spots, grind smooth, take the door and fender back off, Primer and some rattle can paint, seam seal, then rehang the door.

Then I have to fix the inner fender dent, remove 7 spot welds, flatten panels, remove the PO's pop rivets, every other one > plug weld back together.

Been an interesting ride so far. Thanks for your help Folks.

*

Attachments

Last edited:

You done good. The fit looks like a really good starting point when you get ready for final adjustments. Ken

Thanks for the post, I am half way thru the same process

You are welcome... One of the hardest things I have ever done in my Bronco restoration history. Good luck with your project!

South East Florida Refrence

I am looking for a restoration shop in the Fort Lauderdale area with experience restoring these classic Broncos. I am in need of body and mechanical support.

Your experienced response would be greatly appreciated.

I am looking for a restoration shop in the Fort Lauderdale area with experience restoring these classic Broncos. I am in need of body and mechanical support.

Your experienced response would be greatly appreciated.

I need to come back & read this article, but I'd really like to see a post on replacing the post on driver side behind the door. tHE POST THE DOOR LATCHED TOO.

I did mine back in 1990 or so. I need to redo them on both sides. Going to do new kick panels, floor pans, striker posts, and new quarters at the same time. I did mine before the advent of inexpensive mig welders so mine are currently brazed in, so I have that mess to deal with too. Back when I did mine there wasn't nearly the parts support we have today so hopefully this time around things will go together a bit easier. Going to tackle one side at a time. Will hopefully start this winter sometime when its to crappy to be out doing anything else.

- Joined

- Sep 7, 2018

- Messages

- 9

Nice job! Looks like it just need a tiny bit of adjusting and you will be there. May have to do this on my 74 so this is great reference material.

Similar threads

- Replies

- 1

- Views

- 628

- Replies

- 1

- Views

- 775

- Replies

- 0

- Views

- 423

- Replies

- 1

- Views

- 765