Bknaus

New Member

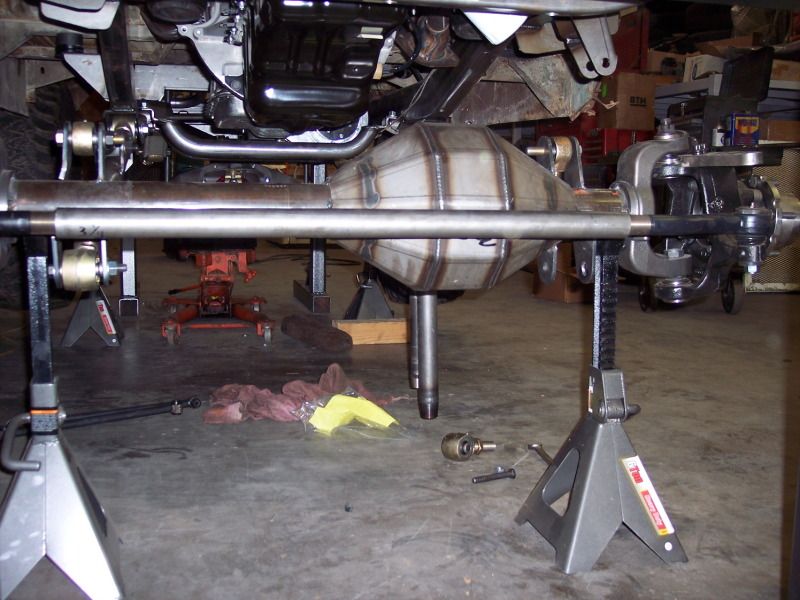

We put the body back on it today to check engine fit, make sure our axles are fairly centered in the wheel wells and make a final decision on tire size.

Getting the body on required trimming the inner fender some, none on the top but some on the edges. Lots of lower, lift, trim, repeat to make sure we don't take more than we need to.

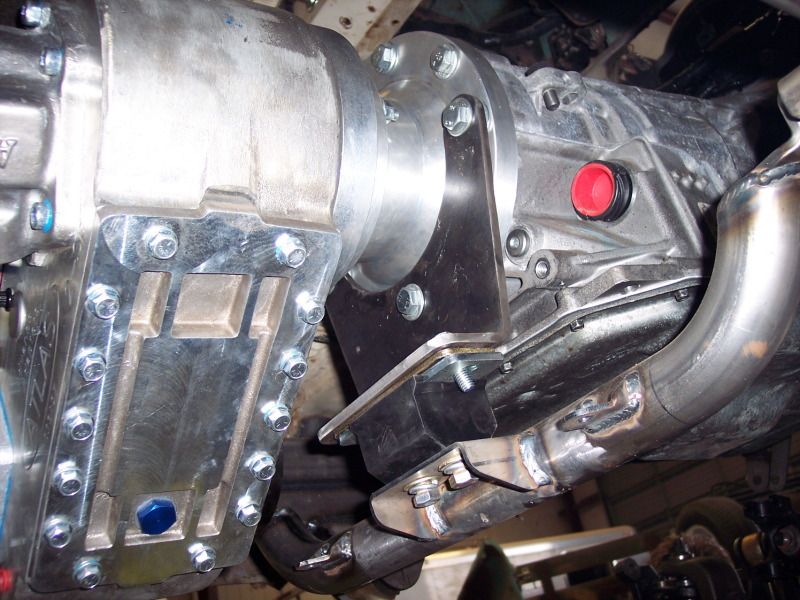

You can see we mostly had to hit the passenger side since the engine is offset that way to allow steering on the driver side. We love the look of the engine in there!

We stole two tires/wheels off our owner's Jeep for test fit purposes and it looks like we're going to add a 1" body lift and run 37s. These pics are with the driver side at full compression.

Getting the body on required trimming the inner fender some, none on the top but some on the edges. Lots of lower, lift, trim, repeat to make sure we don't take more than we need to.

You can see we mostly had to hit the passenger side since the engine is offset that way to allow steering on the driver side. We love the look of the engine in there!

We stole two tires/wheels off our owner's Jeep for test fit purposes and it looks like we're going to add a 1" body lift and run 37s. These pics are with the driver side at full compression.