blazinchuck

Bronco Guru

- Joined

- Jul 14, 2005

- Messages

- 3,319

quick run down...

77 w/ duff arms,4* bushings,cage 3.5" coils,WH 11 leaf 3.5.

the body tends to sit lower on the pass side and little more to the rear(protofab full bumper w/tire and gas can)and now since i put the new motor in...it squats like a 240zx taking off!

so, we took and took measurements of the front. nothing seems to match up to anything. also, before the 3.5" lift was installed it had a complete wh 5.5" lift and 7* bushings.the coils looked great then, but now the dr side coil looks like the bottom is forward. so i thought the stock coil retainers were junked...so i installed the duff lower coil mounts...but didnt help.

...now on the radius arms(trying to check into the "bronco lean fix"). we did as WH has posted before for checking this and correcting this. and at first, it looked like the dr. arm was 1/16th higher than pass.

we have swapped,swapped, and swapped(bushings,caps,lithium greese...and EVENLY TORQUING BOLTS) and i keep ending up with 1",1.5",and 2" difference between the arm and floor(driver arm is always higher than pass side). my floor is not "perfect"...but it aint that dayum far off.when dr. bushings went to pass side(it was the worst-2") swap 1/2 bushings(middle difference-1.5") putting them back like they came off originally was 1"

...please,what it going on????? i have tried to force either arm to gimme the same, but nothing will change these numbers. and im really worried my lean will be worst than it was!!

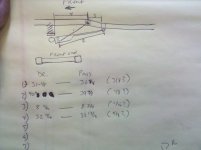

heres a quick pic of some of my notes...

and i even considered maybe a axle tube is tweeked...but some measurements dont show that being the case

77 w/ duff arms,4* bushings,cage 3.5" coils,WH 11 leaf 3.5.

the body tends to sit lower on the pass side and little more to the rear(protofab full bumper w/tire and gas can)and now since i put the new motor in...it squats like a 240zx taking off!

so, we took and took measurements of the front. nothing seems to match up to anything. also, before the 3.5" lift was installed it had a complete wh 5.5" lift and 7* bushings.the coils looked great then, but now the dr side coil looks like the bottom is forward. so i thought the stock coil retainers were junked...so i installed the duff lower coil mounts...but didnt help.

...now on the radius arms(trying to check into the "bronco lean fix"). we did as WH has posted before for checking this and correcting this. and at first, it looked like the dr. arm was 1/16th higher than pass.

we have swapped,swapped, and swapped(bushings,caps,lithium greese...and EVENLY TORQUING BOLTS) and i keep ending up with 1",1.5",and 2" difference between the arm and floor(driver arm is always higher than pass side). my floor is not "perfect"...but it aint that dayum far off.when dr. bushings went to pass side(it was the worst-2") swap 1/2 bushings(middle difference-1.5") putting them back like they came off originally was 1"

...please,what it going on????? i have tried to force either arm to gimme the same, but nothing will change these numbers. and im really worried my lean will be worst than it was!!

heres a quick pic of some of my notes...

and i even considered maybe a axle tube is tweeked...but some measurements dont show that being the case