I moved one back on a 77' model. Because the fuel doors are in the way you can't position a fender flare far enough forward to be centered in the wheel well. I'm still not sure what you're gaining by moving the axle back on an uncut LUBR, and why you need a 6* shim.

I'm running 37" rubber and 5 1/2" of suspension lift. After consulting with Tom Woods driveshaft folks

http://www.4xshaft.com/, and measuring the angle of my pinion in relation to my driveshaft slope/angle I came up with about 6 degree's. All Bronco's are slightly different, however I cant imagine using 3" of suspension and 33" rubber you'll need to move the pinion angle 6*?

I also noticed in your last post some comments about tightening the center pin. The pin through the center of the leaves just keep them in place, but they still gotta move.

Good stuff->

http://www.wildhorses4x4.com/product/Anti-Wrap_Leaf_Spring_Perches,

http://www.wildhorses4x4.com/product/Extreme_duty_U_bolt_kit

One way you may choose is to ditch the shims, don't tighten the center pin and then wait for it to break, and ditch the smallish factory leaf perch. Ruff Stuff sells some dandy leaf spring perch's that are wider and longer than stock

http://www.ruffstuffspecialties.com/catalog/springperchantiwrap.html, and has pre-drilled holes for moving the diff housing forward or rearward about an inch. These new perch's are pretty straightforward, cut the old ones off the housing and then weld the news ones back on in the proper orientation for added degree of pinion tip-up angle greater than stock.

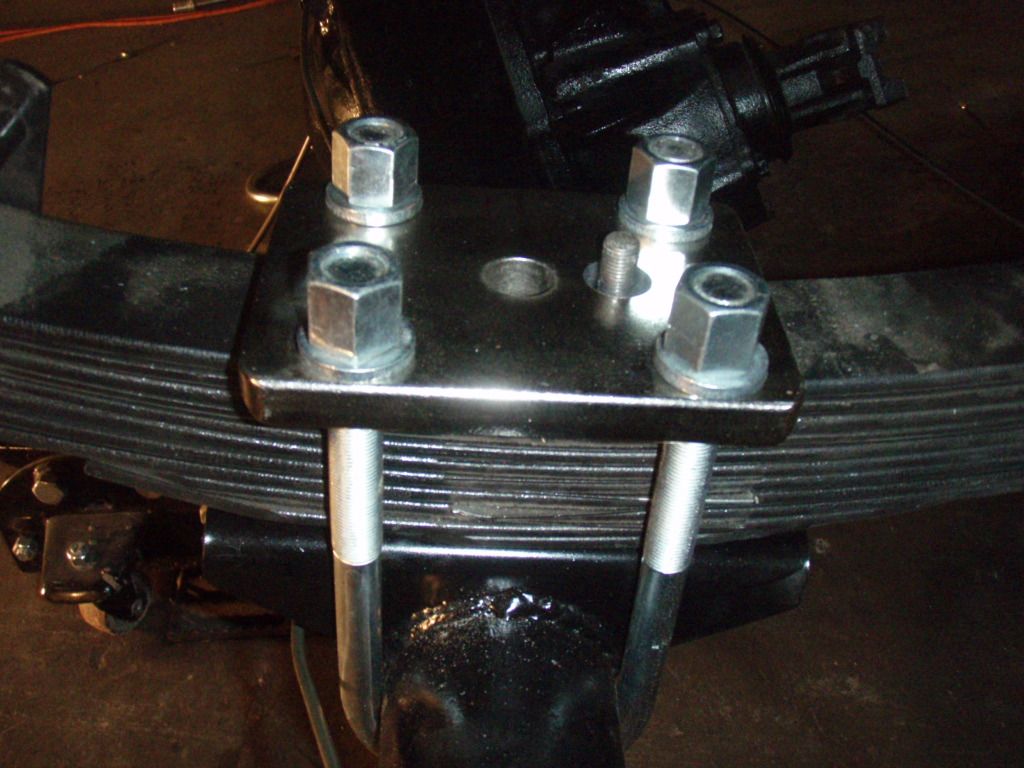

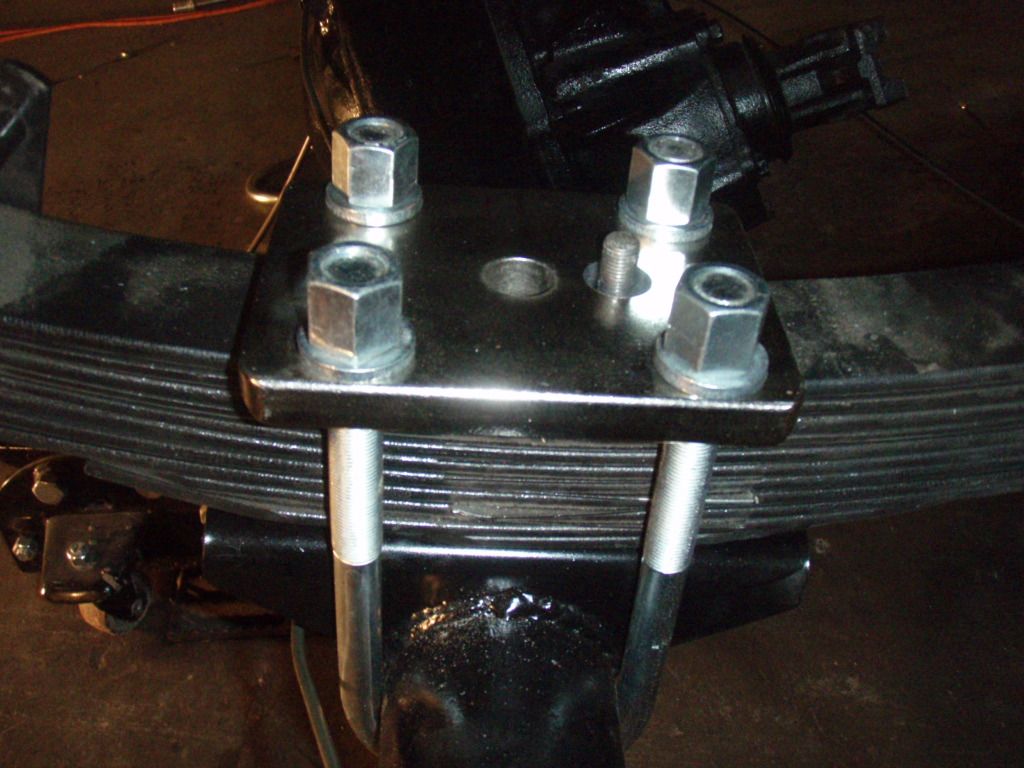

Another signifigant advantage to using the big perch's is they offer more contact surface for reduced axle wrap, and no phoney shims. Believe me, when you offset the diff housing, use a high HP engine, low gears, and big tires the rear diff housing wants to climb and form a new effect of axle wrap. They also have some matching top plates, in my case I already had an extra set of WH heavy-duty top plates so I just drilled some holes in the right places to make everything jive, .....or just get these to make the job simple

http://www.ruffstuffspecialties.com/catalog/UB-PLATES.html

Using these larger perch's my 77' now has very secure and solid mounted leaf springs w/ virtually no axle wrap (also using a WH wrap-trap), perfect pinion angle with no binding -ever- even at full extention of my flexy suspension, plus my axle housing is moved back about an inch to better center the large rubber in the wells