br0nc0xrapt0r

Loves pickles

- Joined

- Sep 28, 2007

- Messages

- 5,437

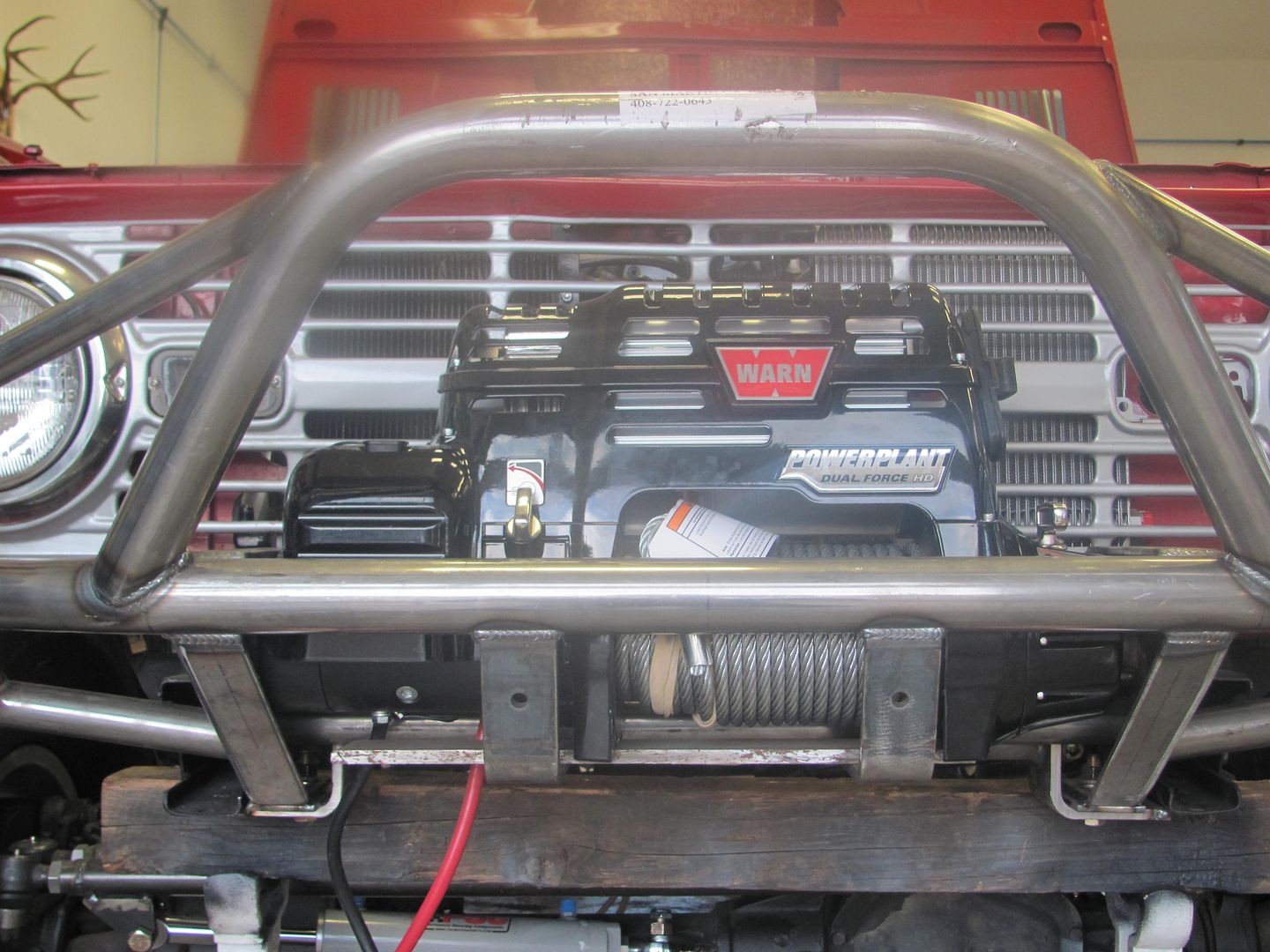

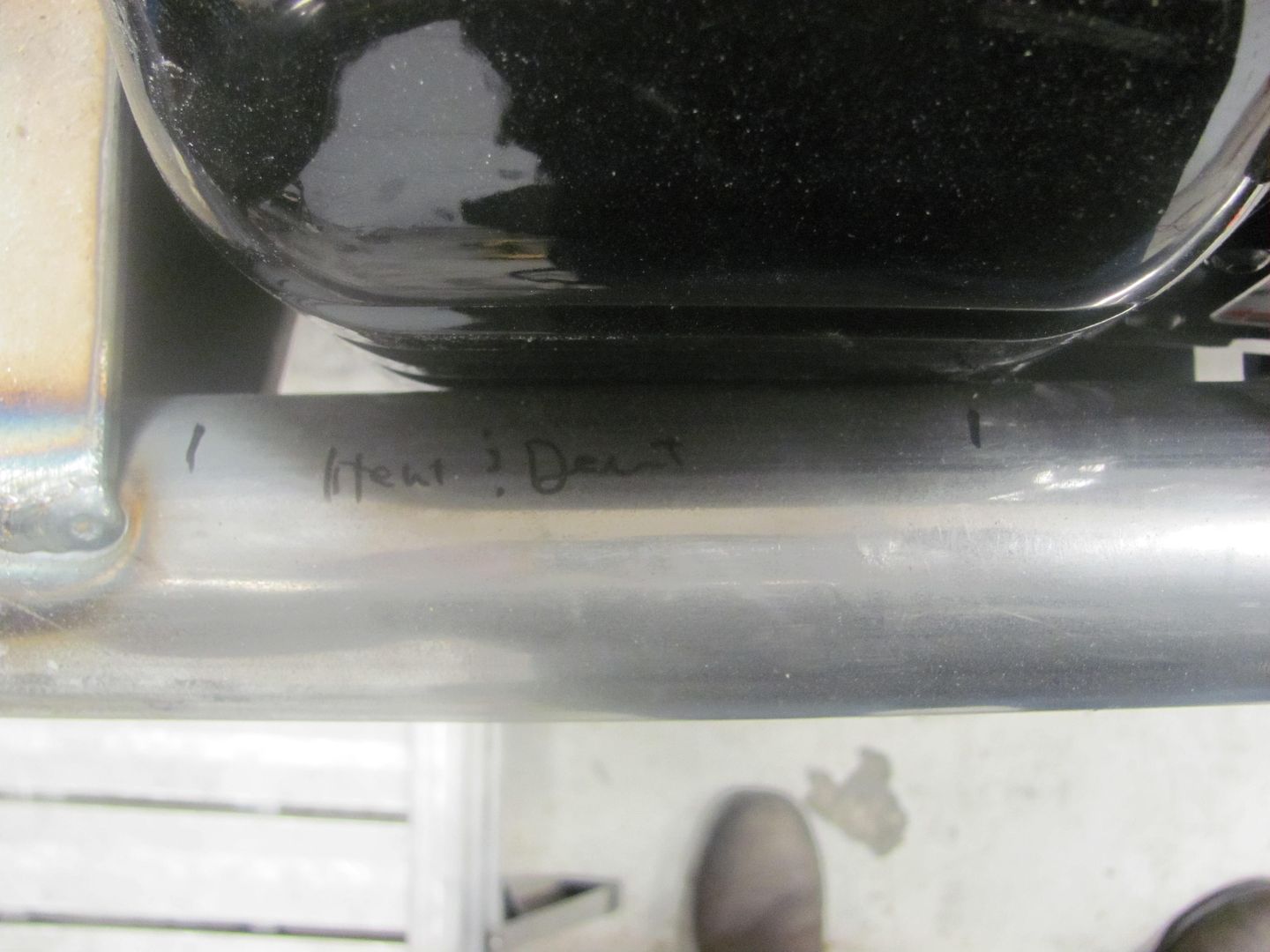

Any reason why you did not extend the Frame mounts to go farther in the frame with square tube? this was something I was thinking of to help distribute lateral force when winching from an angle.