broncobsession

Bronco Guru

- Joined

- Aug 12, 2001

- Messages

- 4,049

Looks great. I'll be moving up to Coralville soon. Would love to see the bronco.

![IMG_20130606_152405_462[1].jpg](/forums/data/attachments/271/271524-5f0eda6b5f06313e0be1a9f9184c47cb.jpg)

![IMG_20130606_141841_742[1].jpg](/forums/data/attachments/271/271518-e6822e62949e5aa948a8768cd267c30b.jpg)

![IMG_20130606_141832_852[1].jpg](/forums/data/attachments/271/271512-97c55fc50fc03db78920bdb9b68f7112.jpg)

![IMG_20130606_141821_845[1].jpg](/forums/data/attachments/271/271507-276da2bac6164af34ff3c851481e25c3.jpg)

![IMG_20130606_141800_849[1].jpg](/forums/data/attachments/271/271501-3759bffe7e237e220ae8a414194dd984.jpg)

![IMG_20130606_141747_027[1].jpg](/forums/data/attachments/271/271494-3696033d3622a9805176143b9dd43fb4.jpg)

![IMG_20130606_141734_398[1].jpg](/forums/data/attachments/271/271489-2d4e40846fd2551efec11408ab859e94.jpg)

![IMG_20130605_163736_429[1].jpg](/forums/data/attachments/271/271483-2a8f8a6a6f311052ffc874570fd59f9e.jpg)

This is pure workshop porn and should be restricted to age 21 and over.

Well done sir.

Two questions, did you do anything to prep the frame before POR application, and anything other than straight POR?

What tranny is that and what body lift?

I'm at the frame mod stage, trying to determine if I want POR, or two stage with hefty additives for chemical resistance. On a frame would you recommend self etching primer, then filler primer, or just a good primer before the paint? Frame will be ground of weld B-B's, somewhat smoothed but not concourse level, then media blasted before paint.

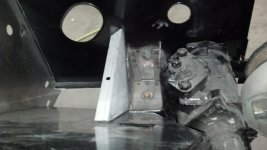

Great work. I've got a question also....I'm fitting up my front clip and find that if I try to set the core support in more straight up and down, it hits the front body mount. If I match the core support more with the front line of the inner fender (greater angle), it's less of a problem. Did you run into this also? Also, the front mount bracket location ends up being up from the bottom of the core support a quarter inch or so if left to fall naturally. I may have got the inner fender welded on a little too angled but the OEM fender seems to follow it pretty well. Any thoughts here? Thanks

I really like your steering wheel, what brand, style is it and how much was it? Where'd u get it from? Thanks trent

Sent from my Kindle Fire using Tapatalk 2

Well had some free time at work today and got the left side tacked in place. Still need to fit the rocker better and finalize the lower qt. alignment. The taillight pocket had been hit before and I had to bust out the slide hammer to get the inner back into shape. All of the tailgate post welds were broken loose on both sides, I threw about 6 spot welds on each side to keep it from happening again. The left side took some serious head scratching to get everything to fit....and I do this stuff for a living. I'm sure most of what I was fighting was the quality of the aftermarket parts. Hopefully tomorrow I will have some time to get everything welded up so I can move on to the front clip. I also want to say the Vise Grip 18DR seems to be designed to hold the eb rocker panel in place for fitment.