brbuilder

Jr. Member

- Joined

- Aug 19, 2007

- Messages

- 163

I thought this would be easy. Get a 3 day tag, get the emissions test, get my plates and be cruising around Chandler, Az. Got the 3-day tag, took it for a ride in the neighborhood and that was the end of easy. Ran great in the garage and on the street at extremely light throttle up to about 2000-2200 rpm. Give it a little more throttle and it falls flat. A major bog, Not a hesitation and it comes back, just nothing. Let off and it will hold about 1500-2000rpm.

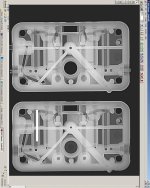

It's a ‘69 302 with performer 289 intake, T/A 470 carb, Cardone electronic distributor, GM 4-pin HEI module, motorcraft TFI coil, resistor wire bypassed, new 8mm wires, Bosh platinum plugs, long tube headers, dual exhaust. I bought the carb used quite some time ago. Previously replaced the needle and seat. Had a small leak at the accelerator pump diaphragm. Replaced that and checked the jets. They were 50's. Stock is 57 so changed them to 57's. Small improvement. Readjusted the idle mixture screws using a vac gauge. Timing was at about 10. Advanced to 18 btdc. Small improvement. I think I've got the accelerator pump lever arm adjusted correctly. Carb has the orange accelerator cam lobe in the number 1 hole.

Don't know if it's a carb issue, ignition issue or something else. Any thoughts, suggestions, comments welcomed and appreciated.

It's a ‘69 302 with performer 289 intake, T/A 470 carb, Cardone electronic distributor, GM 4-pin HEI module, motorcraft TFI coil, resistor wire bypassed, new 8mm wires, Bosh platinum plugs, long tube headers, dual exhaust. I bought the carb used quite some time ago. Previously replaced the needle and seat. Had a small leak at the accelerator pump diaphragm. Replaced that and checked the jets. They were 50's. Stock is 57 so changed them to 57's. Small improvement. Readjusted the idle mixture screws using a vac gauge. Timing was at about 10. Advanced to 18 btdc. Small improvement. I think I've got the accelerator pump lever arm adjusted correctly. Carb has the orange accelerator cam lobe in the number 1 hole.

Don't know if it's a carb issue, ignition issue or something else. Any thoughts, suggestions, comments welcomed and appreciated.