Community

Message Forum

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Buy / Sell

Bronco Tech

3 Arm Wiper Setup

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Install the app

-

Welcome to ClassicBroncos! - You are currently viewing the forums as a GUEST. To take advantage of all the site features, please take a moment to register. It's fast, simple and absolutely free. So please join our community today!If you have problems registering or can't log into your account, please contact Admin.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning...learning

- Thread starter nvrstuk

- Start date

Garry- is this info for me?? If so, I will find out how I check to see if that "Payload.csv" file is missing. THANKYOUI would bet your TPS is working but your Payload.csv file is missing it. The last 3 or 4 updates have been real glitchy and in one case the payload file just disappeared.

I am going to test pin 47 to grd (pin 26) and pin 46 to grd (pin 26), move the throttle and see if I get a reading that varies with the throttle moving. That would prove that the TPS and associated wiring is working and then it could possibly be a connection in the 60 pin harness connector to the ECU but it looks fine.

Here I go... again!

Yes. Find your payload.csv file. You can open it in Office, excel, etc... Make sure TPS is listed in it.Garry- is this info for me?? If so, I will find out how I check to see if that "Payload.csv" file is missing. THANKYOU

Thanks. Will do that todayYes. Find your payload.csv file. You can open it in Office, excel, etc... Make sure TPS is listed in it.

Finished putting together a short block 408 for Tim who you are helping now.

Thanks again. I will look.

FInally got 30 minutes to check pins 46 & pin 47 at my ecu with the key on, engine off.

.9volts at idle & 4.6V at WOT

I knew with 100% certainty that my ECU was receiving a signal from from the TPS but like we all know, we have to eliminate that.

Now to tell my tuner that so we either RE-download Binary Editor again (and hopefully not go thru 2-3 weeks again of "the software doesn't comunicate with my Windows" again like it did earlier OR try something else.

I remember saying back in '96 how EFI when it worked was great but when it didn't you couldn't find a tougher PITA project to troubleshoot! Should have listened to myself! lol

.9volts at idle & 4.6V at WOT

I knew with 100% certainty that my ECU was receiving a signal from from the TPS but like we all know, we have to eliminate that.

Now to tell my tuner that so we either RE-download Binary Editor again (and hopefully not go thru 2-3 weeks again of "the software doesn't comunicate with my Windows" again like it did earlier OR try something else.

I remember saying back in '96 how EFI when it worked was great but when it didn't you couldn't find a tougher PITA project to troubleshoot! Should have listened to myself! lol

Last edited:

Pics?

Where are the pics???

2 & 3 are a 408 short block for my buddy Tim.

Pic #4 is out my shop window.

Smoke!

Visibility is almost 1 mile!

Where are the pics???

2 & 3 are a 408 short block for my buddy Tim.

Pic #4 is out my shop window.

Smoke!

Visibility is almost 1 mile!

Attachments

Ooooooo new toys

Planning ahead!Ooooooo new toys

HIT me alongside the head... too much going on around here. I had to back up for a minute to get a different look.I would bet your TPS is working but your Payload.csv file is missing it. The last 3 or 4 updates have been real glitchy and in one case the payload file just disappeared.

Thanks Garry, I understand what you're saying now. Clint downloaded a new BE Sunday night and the next morning it wouldn't datalog! That simple, thanks Garry!

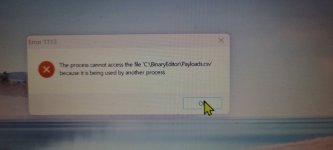

Update: The payload file is wandering around my laptop but can't be utilized by BE for some reason. see screenshot pic

Attachments

Last edited:

That's exactly what happened. The payload file is no longer in BE. The pic above shows it's still in my computer probably causing grief somewhere else...I would bet your TPS is working but your Payload.csv file is missing it. The last 3 or 4 updates have been real glitchy and in one case the payload file just disappeared.

- Joined

- Nov 3, 2003

- Messages

- 49,236

As the peeps at the Volvo factory in Sweden used to say... "The software is never wrong and can't be broken" or words to that effect.

This to my buddy who was so much the go-to Volvo mechanic that even the factory would call him to do some troubleshooting.

But he could never convince them that now and then, the software was just not thinking straight.

Paul

This to my buddy who was so much the go-to Volvo mechanic that even the factory would call him to do some troubleshooting.

But he could never convince them that now and then, the software was just not thinking straight.

Paul

- Joined

- Jun 11, 2004

- Messages

- 11,914

My business is designing, building and supplying advanced marine control systems. I'm constantly reinforcing the fact that control software never has a "mind of its own"..it dutifully repeats the same thread(s) over and over and over... When something isn't working, you find the problem in the I/O or sensors. But the owner's techs tend to look askance at the one thing they understand the least when it comes to troubleshooting a problem onboard the vessel. Blame it on that "black box" with all the magic inside.As the peeps at the Volvo factory in Sweden used to say... "The software is never wrong and can't be broken" or words to that effect.

This to my buddy who was so much the go-to Volvo mechanic that even the factory would call him to do some troubleshooting.

But he could never convince them that now and then, the software was just not thinking straight.

Paul

In a past life I was in charge of QA/QC for a type of metered spray system run off of a PLC. roughly 30 different systems with slightly different programming but otherwise relatively the same. Anyway, they all had their individual quirks on start up but I was always amazed at how after the system had been running for a week everything just kind of smoothed out on its own, almost like it was learning? but I believe this was more about parts wearing in and the individual pieces just working better over time, which made the whole system more functional. I think bronco's are more or less the same.My business is designing, building and supplying advanced marine control systems. I'm constantly reinforcing the fact that control software never has a "mind of its own"..it dutifully repeats the same thread(s) over and over and over... When something isn't working, you find the problem in the I/O or sensors. But the owner's techs tend to look askance at the one thing they understand the least when it comes to troubleshooting a problem onboard the vessel. Blame it on that "black box" with all the magic inside.

Absolutely that's what we blame first! lolMy business is designing, building and supplying advanced marine control systems. I'm constantly reinforcing the fact that control software never has a "mind of its own"..it dutifully repeats the same thread(s) over and over and over... When something isn't working, you find the problem in the I/O or sensors. But the owner's techs tend to look askance at the one thing they understand the least when it comes to troubleshooting a problem onboard the vessel. Blame it on that "black box" with all the magic inside.

In this isolated case it was software and hardware (laptop) software not talking.

I'll confess one of the "software problems was a "mode" setting I had on Mode 3 instead of Mode 2.

Still chuckling because you are right on about the blame!

Similar threads

- Replies

- 8

- Views

- 2K

- Locked

City: Campbell California

Price: $850

- Replies

- 5

- Views

- 637

- Replies

- 5

- Views

- 663