roundhouse

Bronco Guru

- Joined

- Sep 5, 2003

- Messages

- 2,886

Want to replace my track bar mounting bolts.

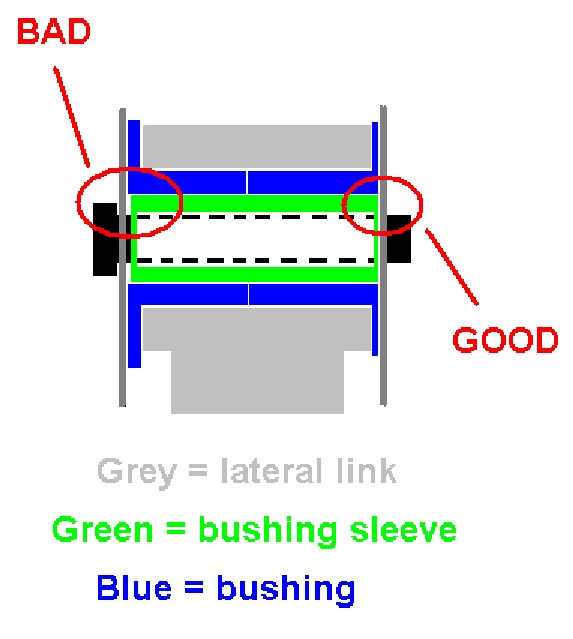

I installed new bushings, and still can see the track bar move about 1/4 inch side to side when someone saws the wheel back and forth.

I can see this movement on both the upper and lower mounts.

I can not see the bolts moving, and we tightened the bolts with a impact wrench,

so apparently the holes are not egged out.

only thing I can figure is the bolts are worn.

new tie rod & drag link from wild horses just arrived,

anyplace sell the proper bolts or am I on my own trying to find a match up a safe bolt at the hardware store?

I installed new bushings, and still can see the track bar move about 1/4 inch side to side when someone saws the wheel back and forth.

I can see this movement on both the upper and lower mounts.

I can not see the bolts moving, and we tightened the bolts with a impact wrench,

so apparently the holes are not egged out.

only thing I can figure is the bolts are worn.

new tie rod & drag link from wild horses just arrived,

anyplace sell the proper bolts or am I on my own trying to find a match up a safe bolt at the hardware store?