- Joined

- Jul 1, 2011

- Messages

- 1,856

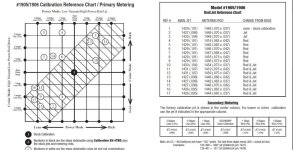

Seems I did pretty good tuning my carb by "feel" and "sound", but I think it could be better. It's currently set at #2, see the pic.

Secondaries are set 1 stage lean. Here's what I saw with the wideband:

@ 3000 feet, where I live:

Idling: 13's-14's

WOT, under load, going uphill - 10's

Cruising: 12's, occasional 13's

@ Sea Level:

Idling: 14's-15's

WOT, still 10's

Cruising: 13's, occasional 14's

What I found interesting was when I was heading back up the hill, half throttle, 2500 RPM. ~55MPH she held in the steady 14,s.

Stomped on it, down to 10's, backed off, back to steady 14's. Slowly worked its way back to 12's as I climbed in elevation.

I was thinking of taking it to #15 with a simple rod change, and taking the secondaries one stage leaner.

Thoughts?

EDIT: I do have my charcoal canister connected to my air cleaner, if that matters.

Secondaries are set 1 stage lean. Here's what I saw with the wideband:

@ 3000 feet, where I live:

Idling: 13's-14's

WOT, under load, going uphill - 10's

Cruising: 12's, occasional 13's

@ Sea Level:

Idling: 14's-15's

WOT, still 10's

Cruising: 13's, occasional 14's

What I found interesting was when I was heading back up the hill, half throttle, 2500 RPM. ~55MPH she held in the steady 14,s.

Stomped on it, down to 10's, backed off, back to steady 14's. Slowly worked its way back to 12's as I climbed in elevation.

I was thinking of taking it to #15 with a simple rod change, and taking the secondaries one stage leaner.

Thoughts?

EDIT: I do have my charcoal canister connected to my air cleaner, if that matters.

Attachments

Last edited: