- Joined

- Oct 29, 2022

- Messages

- 134

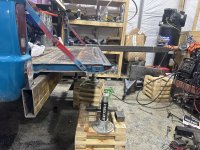

Started taking a welding/offroad fabrication class at the local community college. I've been welding for a decade now, but mostly self taught. I figured some actual instruction wouldn't hurt. As part of the class we are doing a couple of welding projects. The two I decided to do are to build a tire carrier bumper and rock sliders. I've ordered 2x6x3/16 steel for both. I ordered a summit machine spindle and a tire mount similar to the genright style jeep mounts. The bumper plans will be to taper the ends of the bumper up slightly and wrap around the edge with some plate to act as lower corner guards. I have 37x12r17 SX2 tires so I'm trying to figure out how to keep the tire as out of the way as possible. My plans are to have the tire as low as possible to still be able to see out the back window, and to keep it clear of the tail lights. This creates an issue when it comes to departure angles. My current thoughts to help on 2 counts, is to build a small skid underneath the tire. This will act as a shield to protect the tire from sharp dropoffs, following the departure angle to keep out of the way generally, and act as a ledge to rest the tire on when I am tightening the spindle for the tire mount. The tire mount will also be adjustable to allow me to change if I go up or down a tire size in the future. Figuring enough range to cover 35-40" tires. I'll include some rough pictures to see what everyone thinks. But wanted to get some opinions on if this is a terrible idea or if it should work. Also planning to have a cooler mount on the swingout and a small table that will create a small corner with the tailgate to take a break on the trails, grab lunch, etc. Thanks!