abrogate932

Newbie

I am looking for some insight to a transmission issue that only appeared AFTER a rebuild. Last year I had to pull my 302 due to a cracked bearing cap. While the engine was being machined, I decided it was a great opportunity to rebuild the 3.03 RAT transmission and Dana 20. I had started the tear down and rebuild process and then some BS happened in my life and I wasn't able to get things back together as quickly as I had hoped. I had to walk away from things for about five months while I sorted my life out. The trans was partially rebuilt at that time and I am wondering if I made some boneheaded mistake and just forgot something...

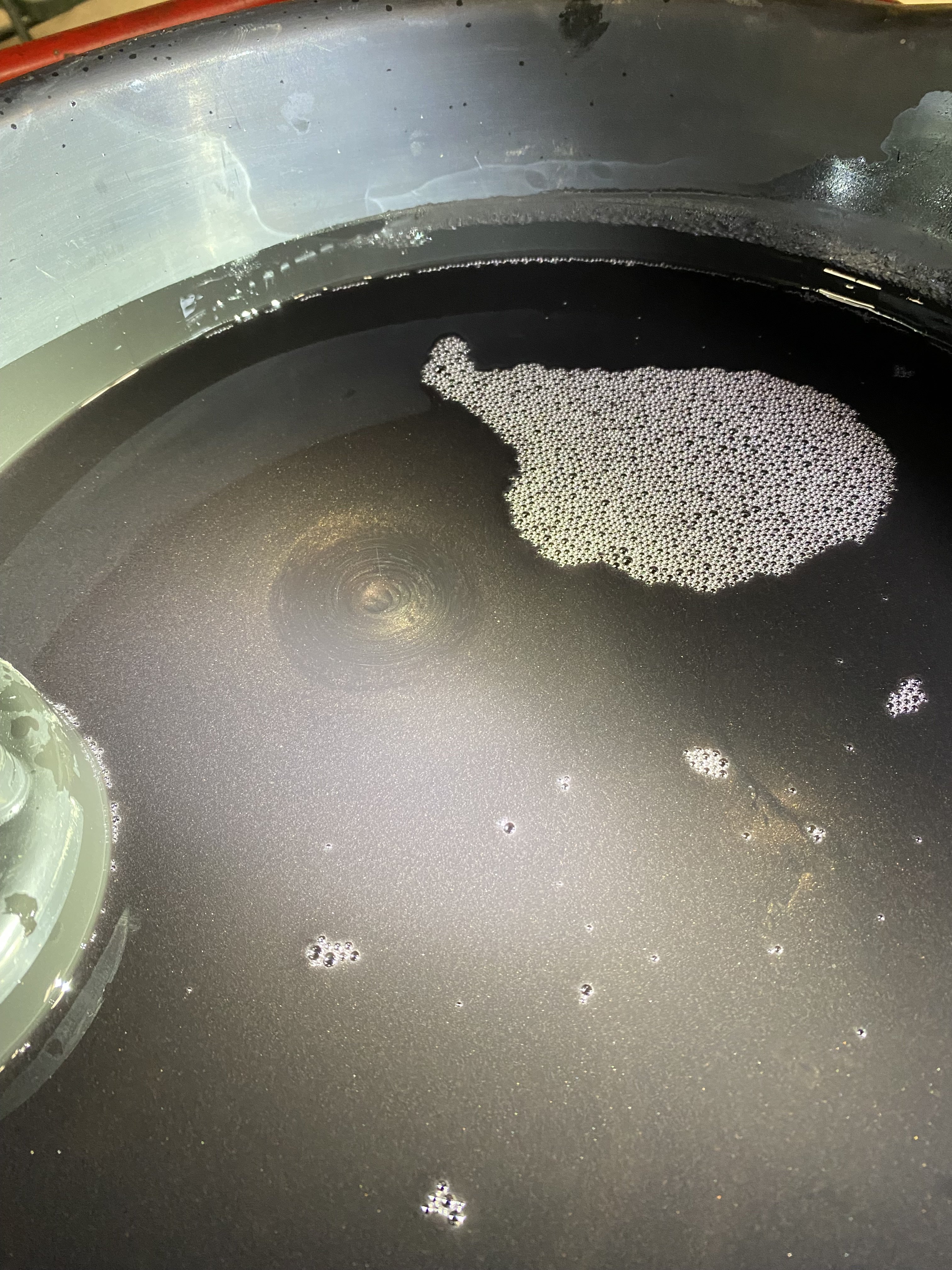

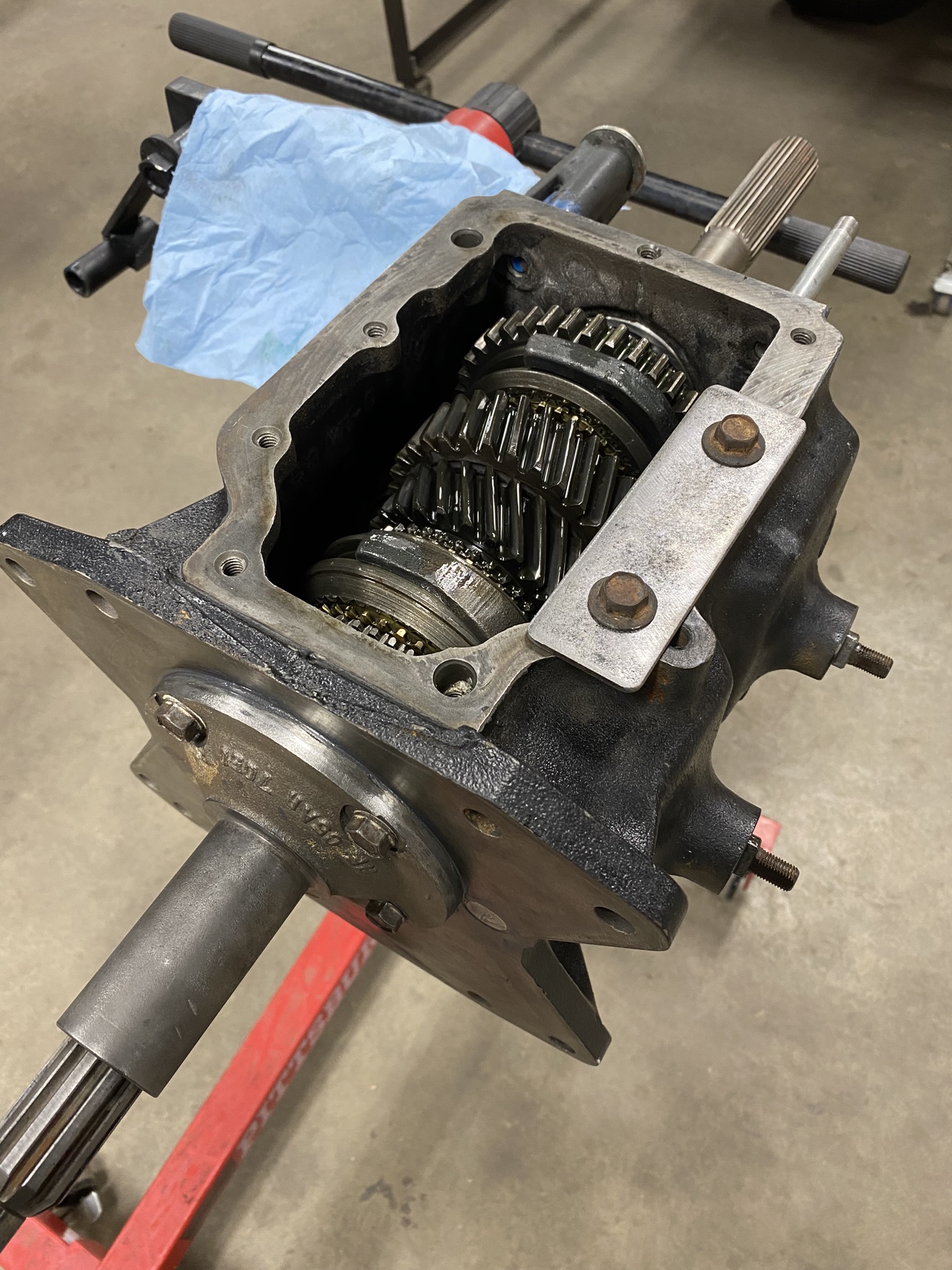

First, lets show some before and after pics just so I can get some attention:

Looks good, right? Well, it doesn't sound good. I used a trans rebuild kit I got from Wild Horses. Everything went smoothly. I also installed a LUK clutch and replaced the clutch fork, pilot bearing and throw out bearing. I finally got the 302 built, painted and installed. I mated the trans and transfer-case and installed the exhaust. I went through the procedure for properly adjusting the clutch and visually verified the throw out bearing is not touching the clutch fingers. I have a "growl" when the clutch is engaged in neutral, 1st, 2nd and 3rd. I do not hear the growl in reverse. The growl immediately goes away with the clutch disengaged (pedal depressed). My Bronco has a Hurst floor shifter, which I had also fully disassembled, cleaned, greased and installed. My initial thought was that I have a shifter linkage issue and that a shift collar is hitting a synchro. This growl is present with the Dana 20 in every position as well. I am almost 100% certain it is coming from the transmission. I went for a test drive hoping to start breaking in my motor, but after less than a mile, I decided I am going to regret not addressing this noise. I plan on pulling the transmission and popping the top off to see if something is obviously wrong. I did take some pictures during the rebuild and was hoping someone else may look at them and possibly notice something I have overlooked. This is not the first trans I have rebuilt and it is by far the most simple that I have. However, I do not want my confidence to blind me.

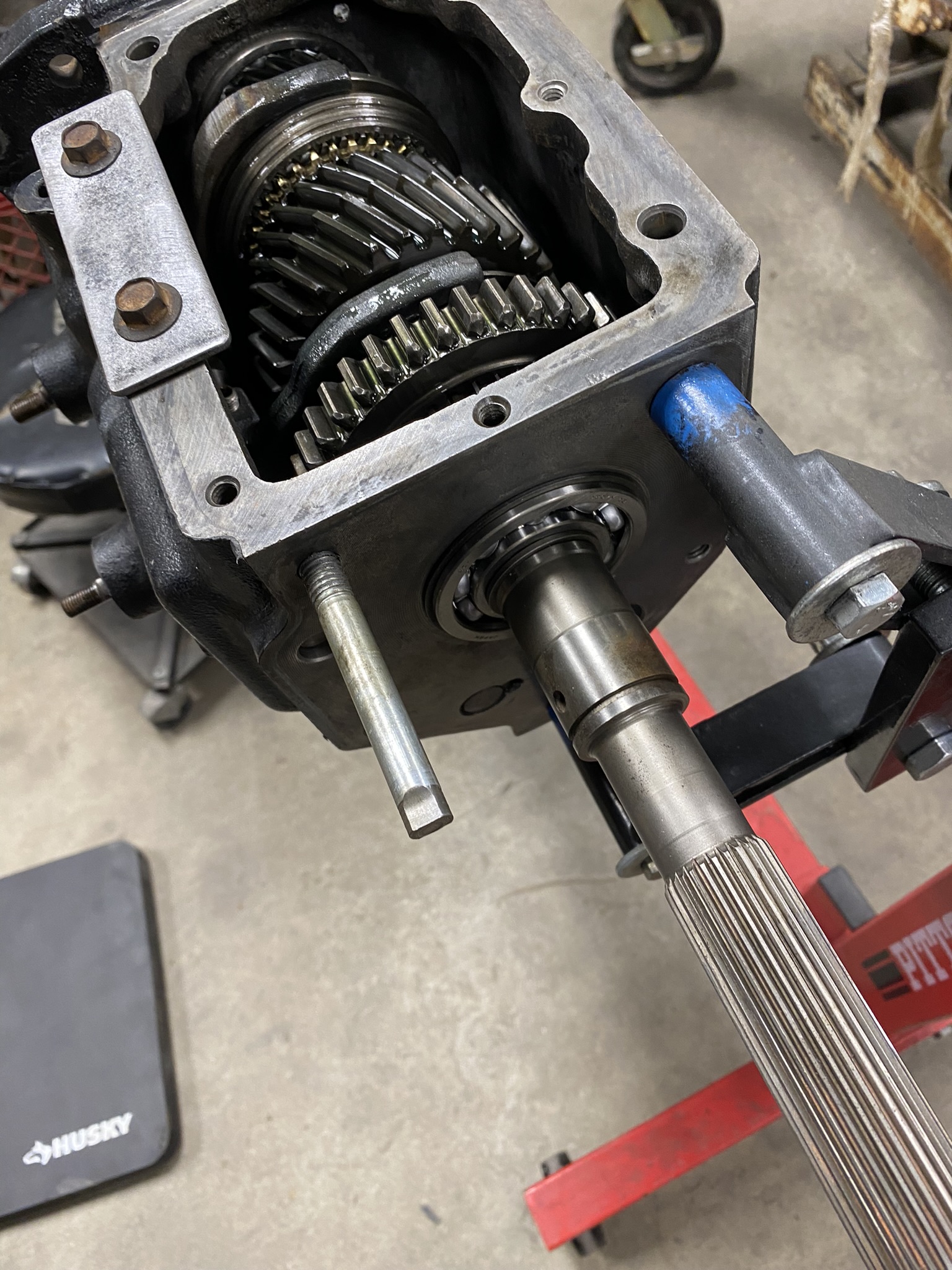

First item that I had to replace for the rebuild was the throw out shaft/input bearing cover (not sure of the correct term)

I was perplexed how bad this component was, as I had no obvious drivability issues before. Hard to believe, right? I found a numbers matching bearing cover and checked its critical dimensions and it matched. The groove on the tip was from the bearing, the groove in the middle was from the clutch fork. Someone had previously welded the cracked spring retainer clip.

The 2nd/3rd shift rail freeze plug was damage when removing it and the only replacement that I could find was this one from Melling. It is not a perfect match and the dome required me to punch it flat. I do not believe the shift rail makes contact with this internally, however I wanted to show this incase I am overlooking it and and wrong.

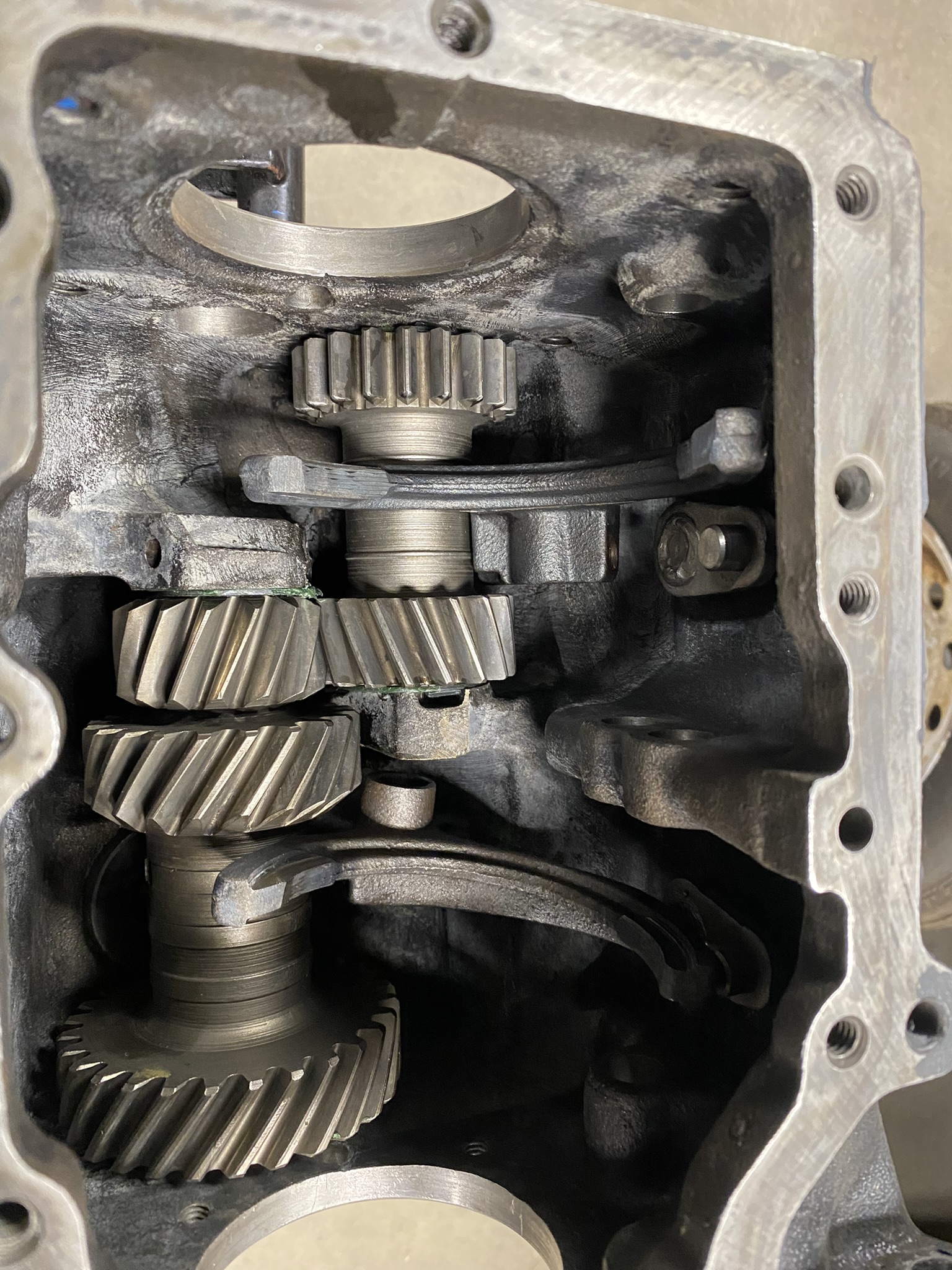

Everything looks correct in these pictures, at least to me. The only thing I notice is that the 2nd/3rd shift collar has two grooves on one end and one on the other. This is one item that has me scratching my head. This is the orientation the collar was in upon tear down, but the rebuild documentation I have does not indicate a direction.

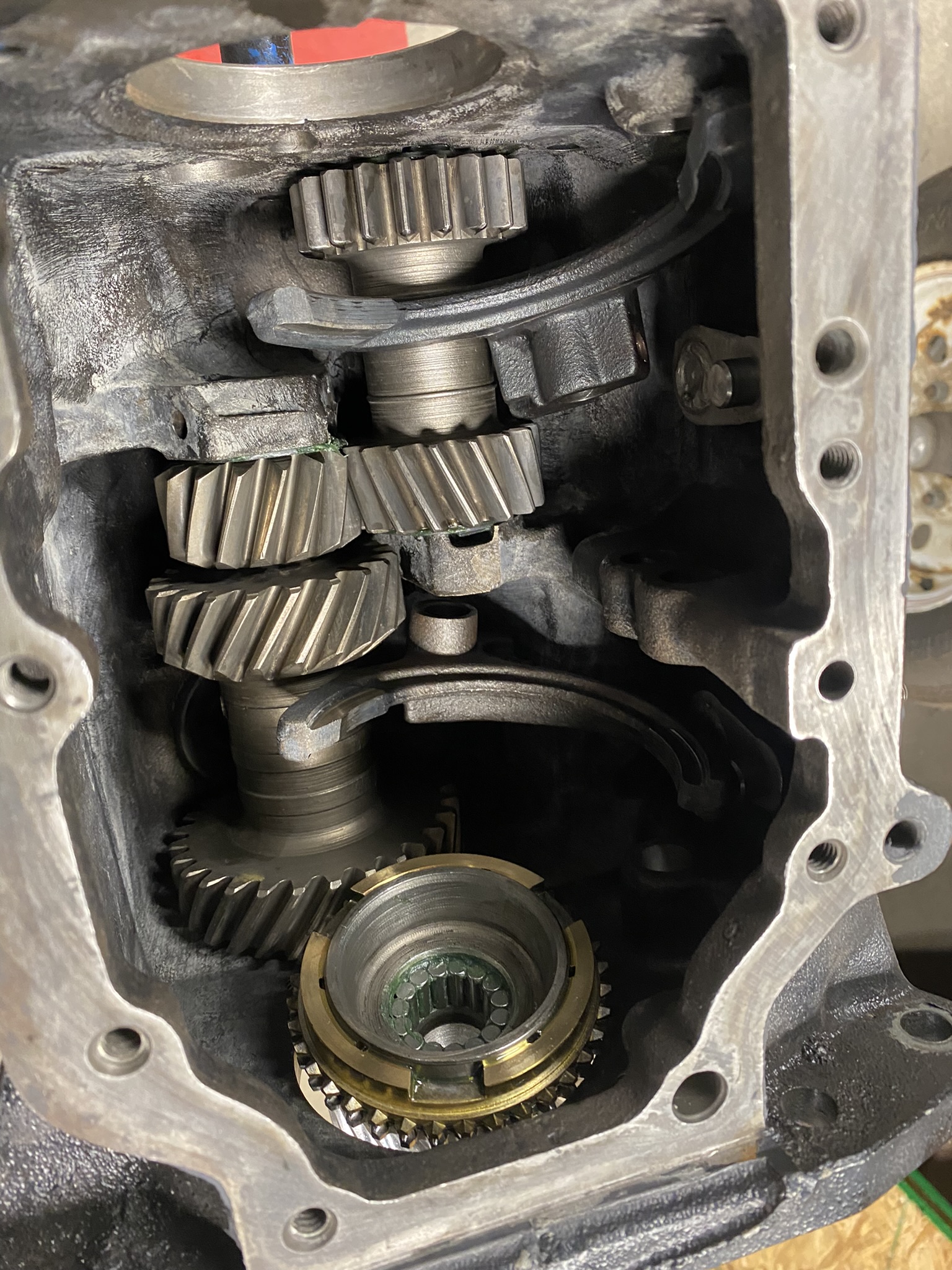

Upon teardown, one of the synchro insert springs was broken and sitting in the bottom of the trans. This had me scratching my head, but they would be replaced later so I didn't dwell on it. I am wondering now if maybe a synchro insert or spring moved or something.

I have more pics, but I don't know that they would help. Other information that may be helpful is that I can shift into and drive in all forward gears and reverse. The noise is the worst in 2nd, moderate in 1st and faint in 3rd. You can hear the noise over the exhaust. I would call it a growl, but not really a grinding. I am using Royal Purple 75W90 Synthetic for oil and I have verified it is at the correct level.

Thoughts?

Thanks!

First, lets show some before and after pics just so I can get some attention:

Looks good, right? Well, it doesn't sound good. I used a trans rebuild kit I got from Wild Horses. Everything went smoothly. I also installed a LUK clutch and replaced the clutch fork, pilot bearing and throw out bearing. I finally got the 302 built, painted and installed. I mated the trans and transfer-case and installed the exhaust. I went through the procedure for properly adjusting the clutch and visually verified the throw out bearing is not touching the clutch fingers. I have a "growl" when the clutch is engaged in neutral, 1st, 2nd and 3rd. I do not hear the growl in reverse. The growl immediately goes away with the clutch disengaged (pedal depressed). My Bronco has a Hurst floor shifter, which I had also fully disassembled, cleaned, greased and installed. My initial thought was that I have a shifter linkage issue and that a shift collar is hitting a synchro. This growl is present with the Dana 20 in every position as well. I am almost 100% certain it is coming from the transmission. I went for a test drive hoping to start breaking in my motor, but after less than a mile, I decided I am going to regret not addressing this noise. I plan on pulling the transmission and popping the top off to see if something is obviously wrong. I did take some pictures during the rebuild and was hoping someone else may look at them and possibly notice something I have overlooked. This is not the first trans I have rebuilt and it is by far the most simple that I have. However, I do not want my confidence to blind me.

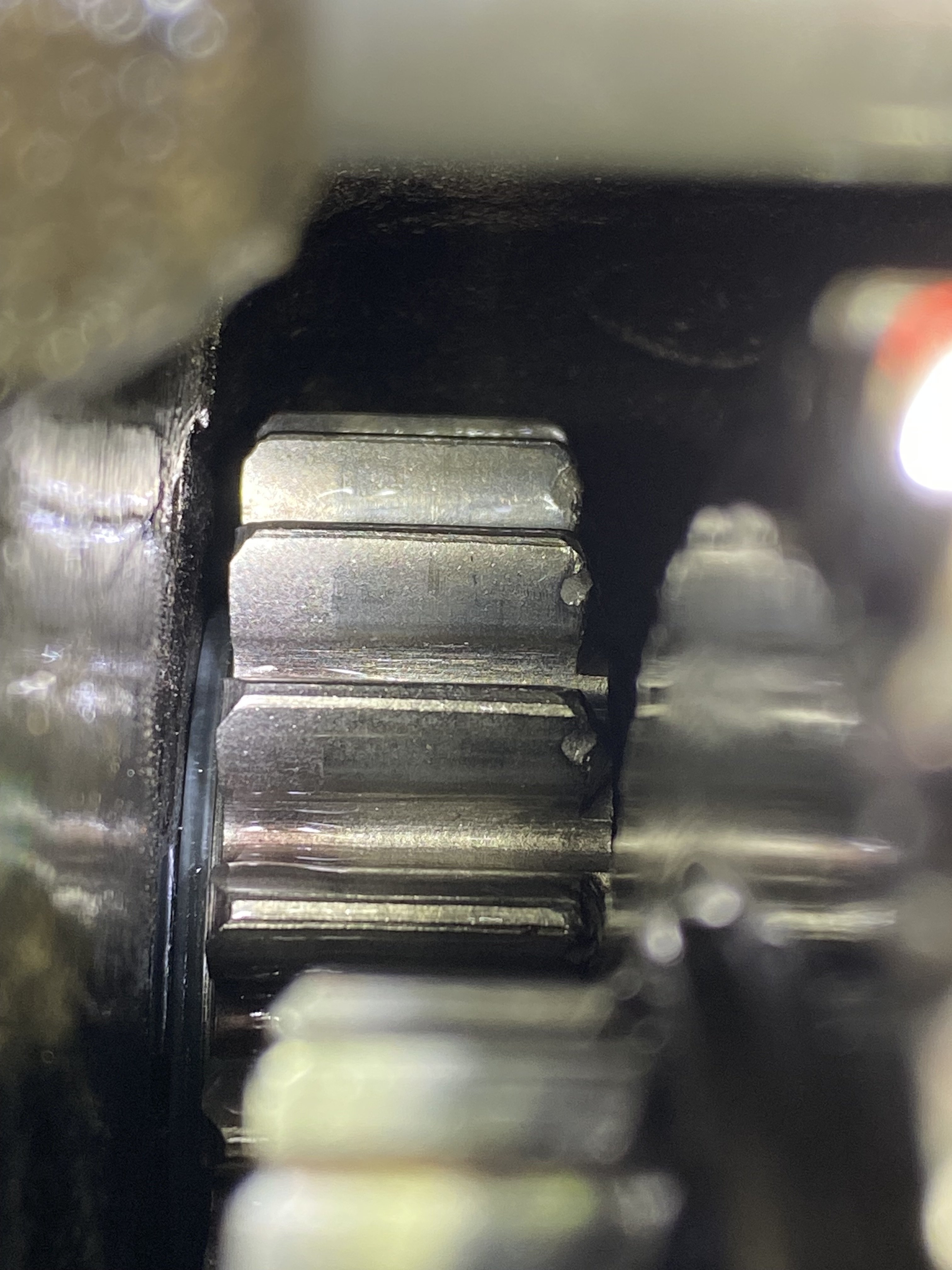

First item that I had to replace for the rebuild was the throw out shaft/input bearing cover (not sure of the correct term)

I was perplexed how bad this component was, as I had no obvious drivability issues before. Hard to believe, right? I found a numbers matching bearing cover and checked its critical dimensions and it matched. The groove on the tip was from the bearing, the groove in the middle was from the clutch fork. Someone had previously welded the cracked spring retainer clip.

The 2nd/3rd shift rail freeze plug was damage when removing it and the only replacement that I could find was this one from Melling. It is not a perfect match and the dome required me to punch it flat. I do not believe the shift rail makes contact with this internally, however I wanted to show this incase I am overlooking it and and wrong.

Everything looks correct in these pictures, at least to me. The only thing I notice is that the 2nd/3rd shift collar has two grooves on one end and one on the other. This is one item that has me scratching my head. This is the orientation the collar was in upon tear down, but the rebuild documentation I have does not indicate a direction.

Upon teardown, one of the synchro insert springs was broken and sitting in the bottom of the trans. This had me scratching my head, but they would be replaced later so I didn't dwell on it. I am wondering now if maybe a synchro insert or spring moved or something.

I have more pics, but I don't know that they would help. Other information that may be helpful is that I can shift into and drive in all forward gears and reverse. The noise is the worst in 2nd, moderate in 1st and faint in 3rd. You can hear the noise over the exhaust. I would call it a growl, but not really a grinding. I am using Royal Purple 75W90 Synthetic for oil and I have verified it is at the correct level.

Thoughts?

Thanks!