CopperBronco

Jr. Member

- Joined

- Aug 13, 2021

- Messages

- 379

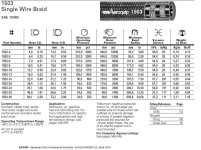

Quick question about AN fittings, making my own braided lines with AN fittings for first time. Can anyone confirm the following?

You’re supposedly meant to leave a 1/16” gap between AN fittings when you tighten the two pieces together onto the braided hose? Any risk of leaks since I tightened down flush, and then had to back off 1/16”?

Second for NPT/pipe thread ends you should use high heat thread sealant or 2-3 wraps of Teflon tape, and aim to get at least the width of the bolt into the fitting as you tighten down, usually 4-5 threads minimum.

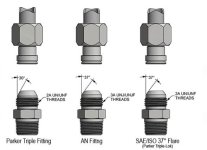

Lastly for the flared 37 degree AN fittings, you shouldn’t use any Teflon tape or thread sealant as the angled flare is what is sealing up, not the threads. Some say add a little oil, do you just use the type of oil that will be running through lines? In this instance it’d be trans fluid, as these are my trans cooler lines.

Many thanks, just trying to do this right and avoid leaks.

You’re supposedly meant to leave a 1/16” gap between AN fittings when you tighten the two pieces together onto the braided hose? Any risk of leaks since I tightened down flush, and then had to back off 1/16”?

Second for NPT/pipe thread ends you should use high heat thread sealant or 2-3 wraps of Teflon tape, and aim to get at least the width of the bolt into the fitting as you tighten down, usually 4-5 threads minimum.

Lastly for the flared 37 degree AN fittings, you shouldn’t use any Teflon tape or thread sealant as the angled flare is what is sealing up, not the threads. Some say add a little oil, do you just use the type of oil that will be running through lines? In this instance it’d be trans fluid, as these are my trans cooler lines.

Many thanks, just trying to do this right and avoid leaks.

Last edited: