malcolmzilla

Bronco Guru

Yes and no.

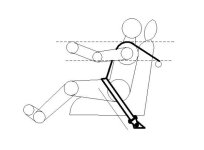

I haven't bent anything from the wrong end or in the wrong plane this time, so thats good, even did a couple reverse bends. This is my 3rd cage, well 2 and 1/2 really...

Despite all my math and measuring, there was some trial and error and wasted tube, esp. on the A's thru the dash. and eyeball work the overhead spreaders. Notching by hand for the nodes take a long time.

I am really liking the lines of it. I did want something both functional and aesthetic. I hope the spare carrier turns out as I envision, and the ERW is adequate, in hindsight DOM might have been better but my brother (weld tech.) figures the design is the most important thing.

However, my brother is pissed at the amount of TIG work he has to do! ;D We did fill some of the wider notches with MIG 1st and will go over with TIG to look purty, MIG piles up a lot. Frame tie-ins will be MIG'd (out of sight).

I haven't bent anything from the wrong end or in the wrong plane this time, so thats good, even did a couple reverse bends. This is my 3rd cage, well 2 and 1/2 really...

Despite all my math and measuring, there was some trial and error and wasted tube, esp. on the A's thru the dash. and eyeball work the overhead spreaders. Notching by hand for the nodes take a long time.

I am really liking the lines of it. I did want something both functional and aesthetic. I hope the spare carrier turns out as I envision, and the ERW is adequate, in hindsight DOM might have been better but my brother (weld tech.) figures the design is the most important thing.

However, my brother is pissed at the amount of TIG work he has to do! ;D We did fill some of the wider notches with MIG 1st and will go over with TIG to look purty, MIG piles up a lot. Frame tie-ins will be MIG'd (out of sight).

Last edited: