blubuckaroo

Grease Monkey

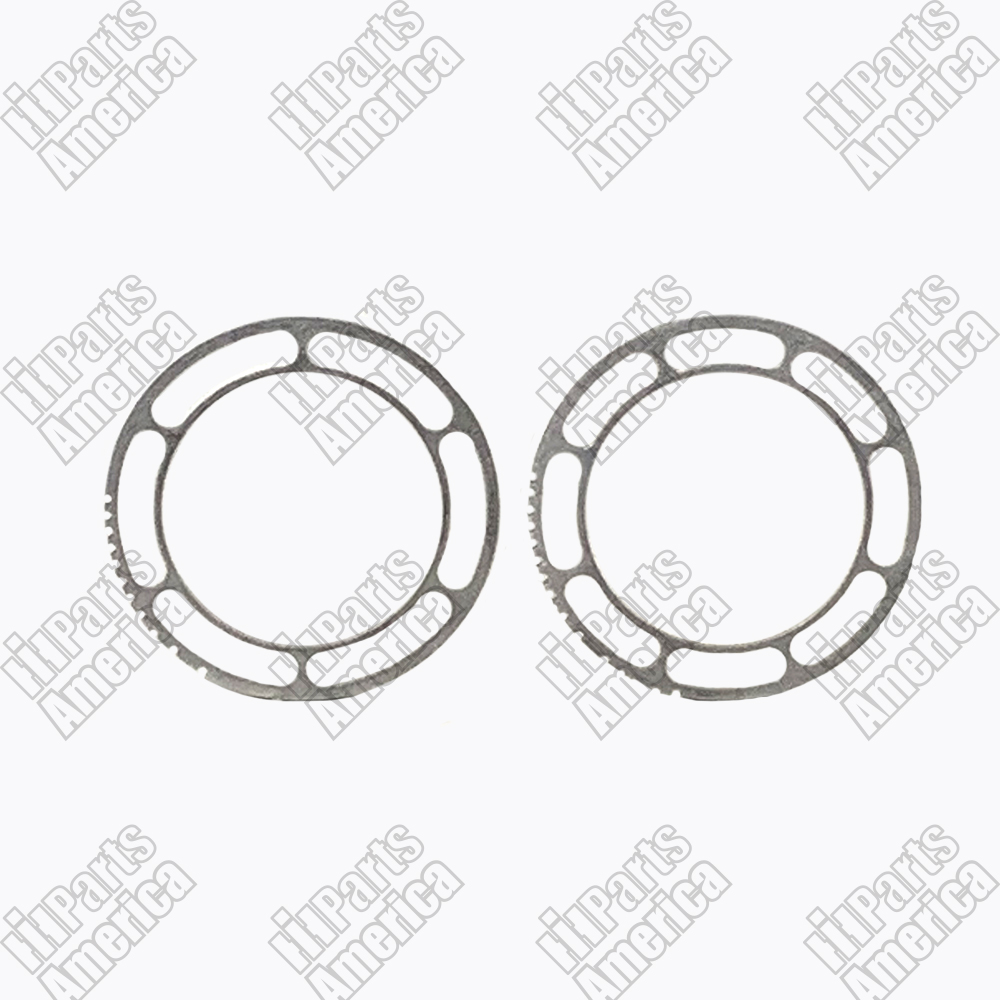

I previously had an alignment correct the passenger side camber with an eccentric sleeve. Now years later, that ball joint is showing looseness.

I plan to replace the ball joints, but studying these adjuster, I can't understand how they can have proper ball joint pre-load, and have the eccentric adjusted at precisely the right angle at the same time.

I'm suspicious that's why my ball joint failed. I'm thinking the sleeve was adjusted to correct my camber issue without regard to proper pre-load.

Could someone explain to me how these adjusters could be used correctly?

I plan to replace the ball joints, but studying these adjuster, I can't understand how they can have proper ball joint pre-load, and have the eccentric adjusted at precisely the right angle at the same time.

I'm suspicious that's why my ball joint failed. I'm thinking the sleeve was adjusted to correct my camber issue without regard to proper pre-load.

Could someone explain to me how these adjusters could be used correctly?