So the pressure spring pushes the inner clutch ring off the axle shaft completely? I assume this must be the case, since i don't see a way to force the axle shaft sleeve and clutch ring to separate when I unlock the hub.

Not quite, but not sure if you just worded it oddly or not.

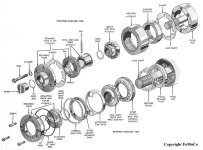

The inner ring does not slide off the axle shaft. But it does slide off of (out of engagement with) the axle shaft sleeve. Is that what you meant?

Engaged and disengaged is only between the inner clutch ring and the axle shaft sleeve. Each will always stay engaged to their splined counterparts. So all longitudinal splines, whether on the axle shaft or the outer hub, stay engaged with something in the locking mechanism.

Locking and unlocking the axle to the hub takes place when the clutch ring and shaft ring move in and out in relation to each other to engage or disengage the square dog teeth. (If that's what that type of interface is called that is? I've always called them "dog teeth" but never heard from a machinist what they are for sure.)

As others have said, disengagement is all done by the actuating knob pushing on the two ears of the actuating cam, which pushes the clutch ring/gear inward and out of contact with the axle sleeve.

Engagement is done by the actuating knob releasing pressure on the actuating cam and the spring pushing outward on the inner clutch ring until the teeth line up and click into position.

Simple, eh?%)

One aspect of this design is that if the outer knob is ever knocked off (a very common thing back when 6" wide wheels were the norm) and the lockout parts exposed, the spring will keep the mechanism engaged and the truck in 4wd still.

The aftermarket hubs such as Warn and others will fail into the unlocked position if something happens.

With deeper dish wheels (negative offset) this is not as much of a problem. It can still happen on the rocks, or with aftermarket hubs breaking under pressure, but not as often as in the old days.

But either way, if the hub end is open and inner workings exposed, simply cover up the hole with a plastic bag and a rubber band, or a rag and a zip-tie, or whatever you've got. Since the wheel bearings are separate from the lockouts, you're still mobile and you just need to keep the dirt, moisture and whatever other off-road demons want to get in there and wreak havoc.

Paul