- Joined

- Nov 28, 2001

- Messages

- 10,508

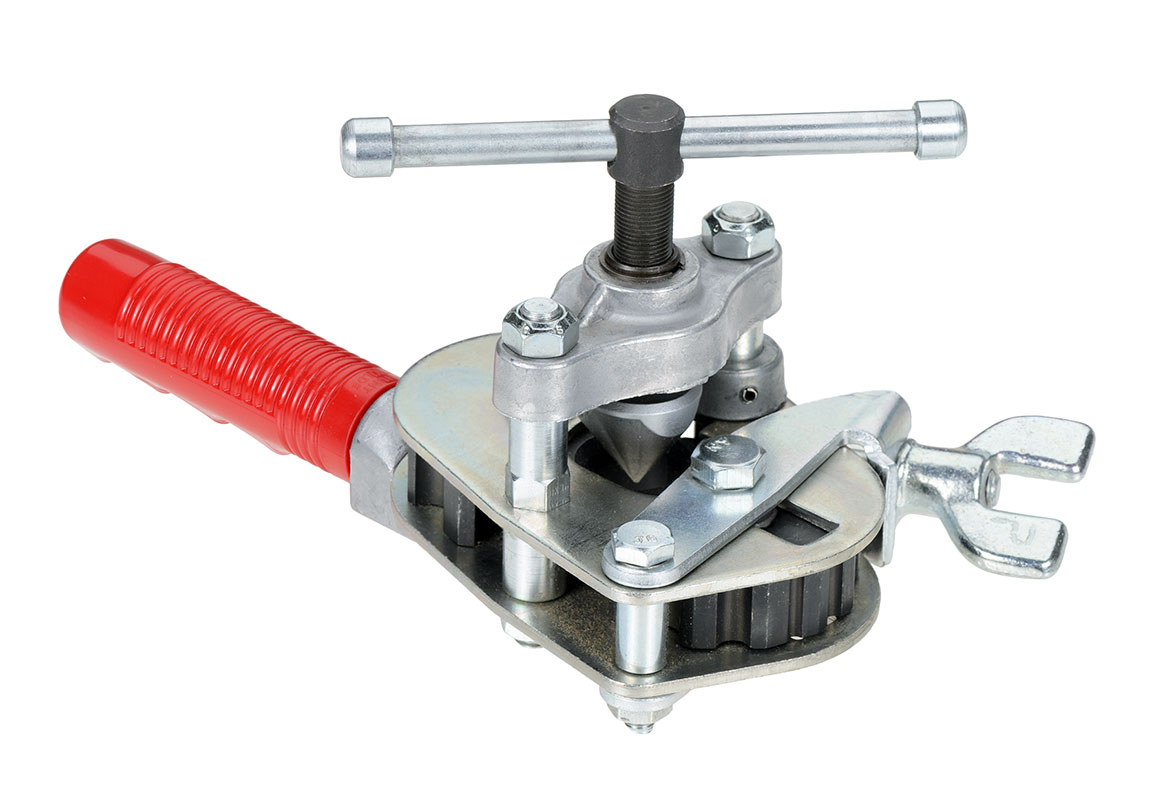

I believe these Fragola fittings would work for the EFI pressures?The problem I keep coming up against with hard lines is making that transition from hard to whatever, in my case AN hoses (I use PTFE braided and cut it with a simple cutter-no problem there). But getting an N fitting on a hard line is the issue. With aluminum tube, there are compression fits. But the problem is those are not rated for EFI pressures, So you need to use steel. But there are no compression fittings for steel with EFI pressure rating that I know of, just weld on stuff. Please tell me I am wrong and make my day!

https://www.summitracing.com/parts/...EIgL0Lh67qYW83kZteh3sO6kn05l1IwRoCAxEQAvD_BwE

Todd Z.