update Feb 6, 2005

not much progress today. I basically was out of sheilding gas, should get some tomorrow, (taking off to spend the day with the kiddies).I did however get the chance to drill out all my holes for my plug welds in the front pan section. Somehow I'm off nearly 3/8" but its something I can live with.

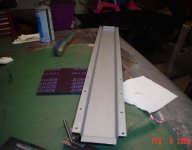

I finally took some good advice and screwed down my new front pan with self tapping screws that way all I have to do tomorrow is just weld it in. (thanks for that tip taxx/trailphyco). anyways heres a couple pictures. Better update tomorrow I hope.

Ben

not much progress today. I basically was out of sheilding gas, should get some tomorrow, (taking off to spend the day with the kiddies).I did however get the chance to drill out all my holes for my plug welds in the front pan section. Somehow I'm off nearly 3/8" but its something I can live with.

I finally took some good advice and screwed down my new front pan with self tapping screws that way all I have to do tomorrow is just weld it in. (thanks for that tip taxx/trailphyco). anyways heres a couple pictures. Better update tomorrow I hope.

Ben