Well, I can't say anything from the pics this time. But thanks for so many pics though!

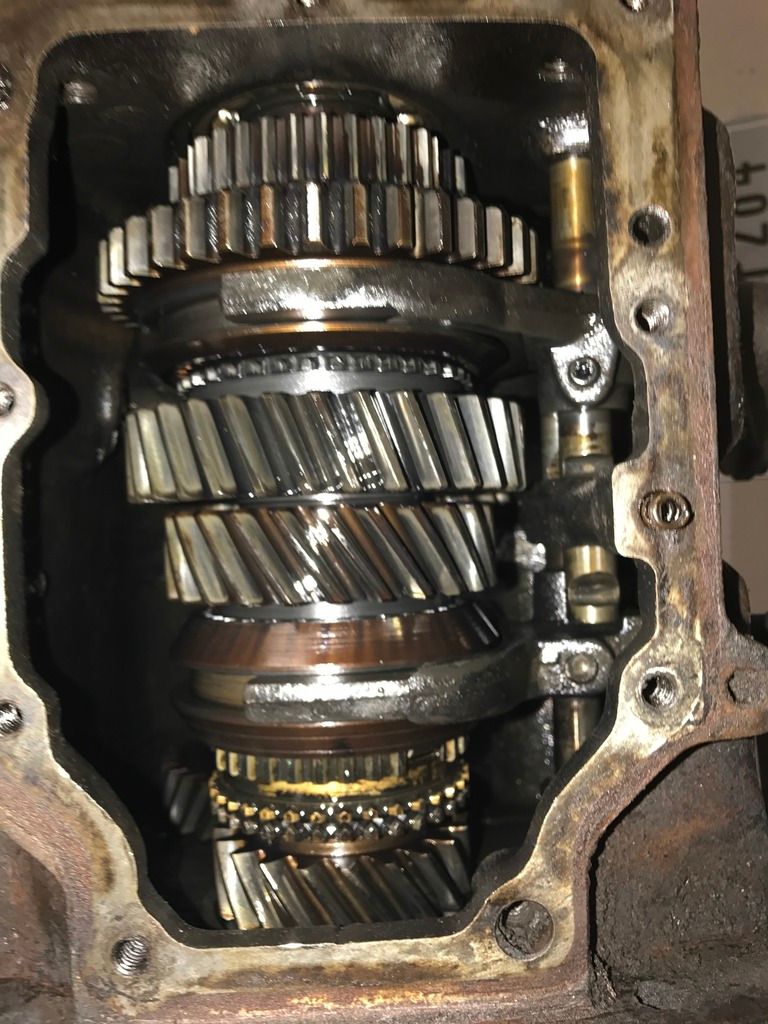

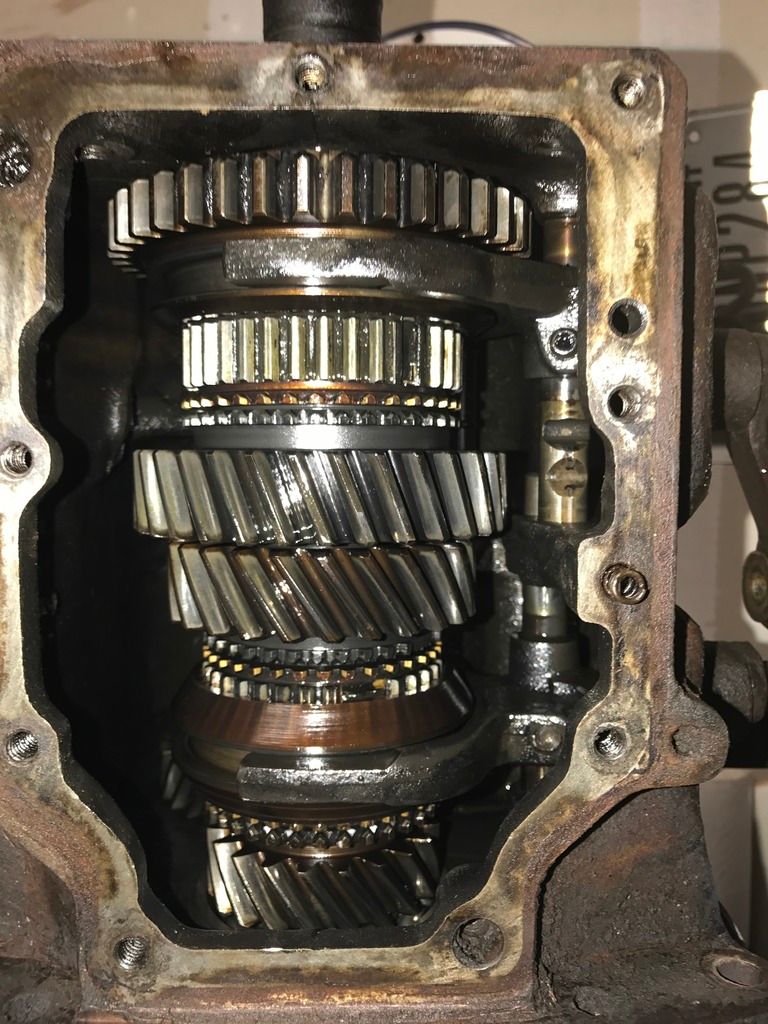

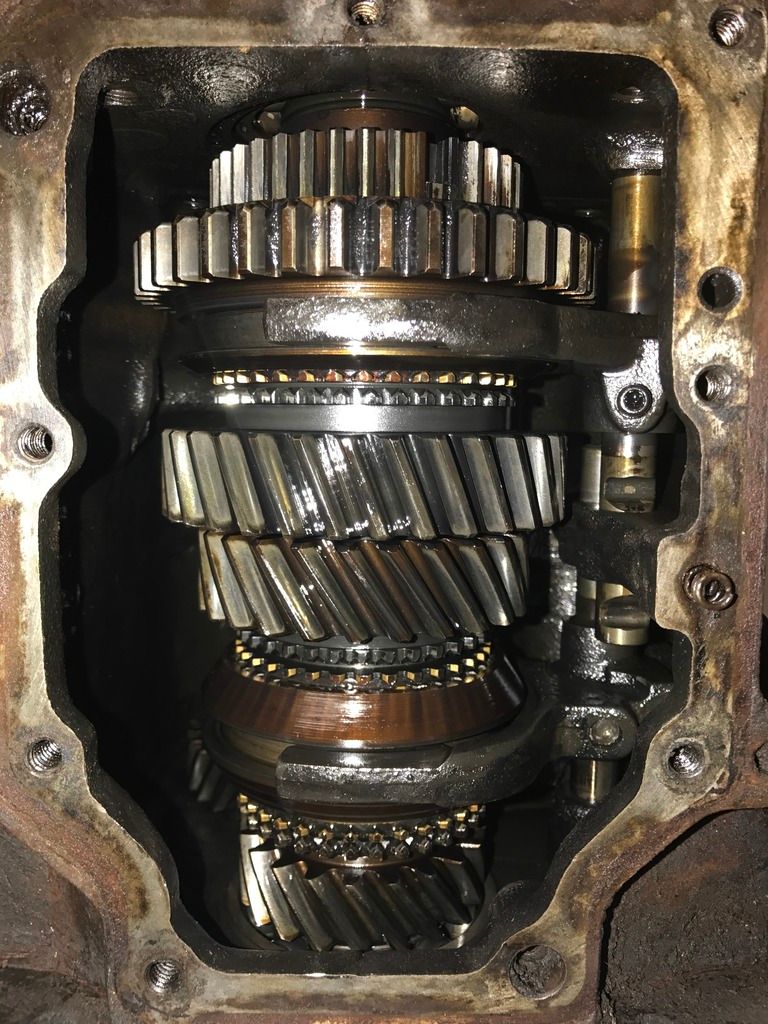

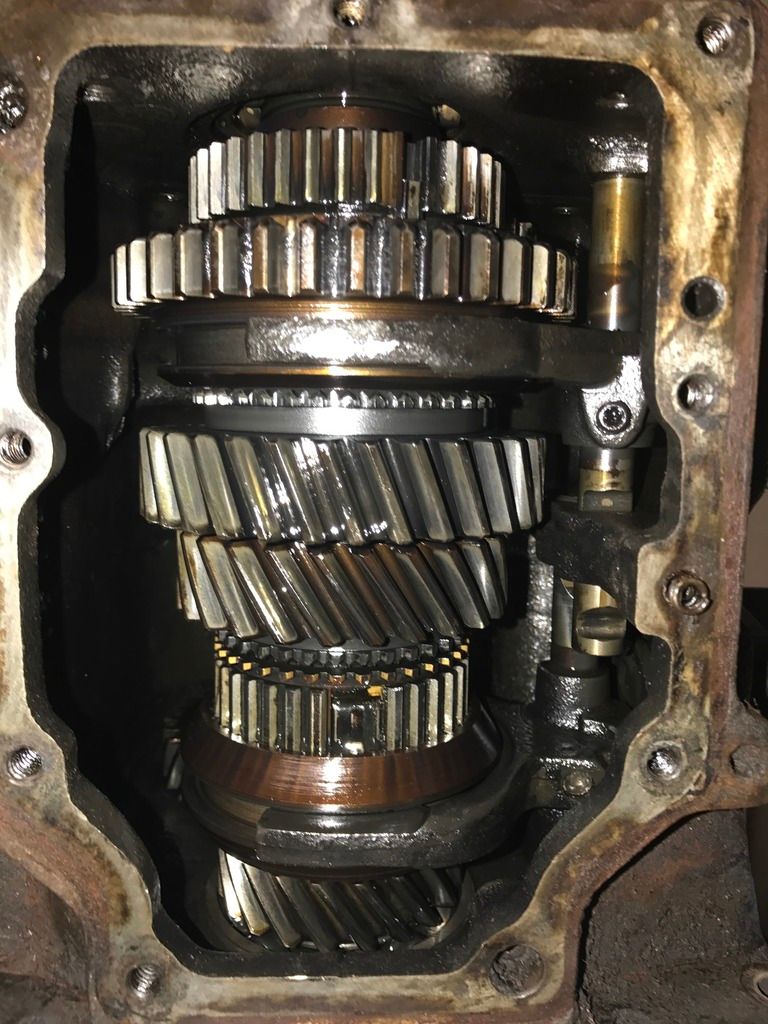

Can't see the trouble from here (I can't at least) and would need to see a more close-up shot of the blocking rings/synchronizers to see if they need replacing. They actually look pretty good from here, but "here" is too far away.

And frankly, if I was tearing into a gear box with unknown mileage (or mileage known to be high) I would just buy all new stuff for it.

I had a distinct advantage of time when I did mine. The total cost for every bearing, bushing, seal and thingy was just over $45 bucks and I was back on the road in fine style. I'm sure the same parts are probably $145 by now! But it might just be worth it "while you're in there" if you're planning to keep the trans and Bronco for awhile still

However, if you're confident that it shifted decently enough for your uses and you just want to get it back on the road, I'd say you're wastin' daylight man!!

If it still won't go back together after all this fiddling about, you likely have at least one roller dislodged and in the way from you getting it pushed all the way in. If so, time to tear it apart.

If you do, I would also have to say that, AT THE VERY LEAST, you should replace the main input and output bearings. They're probably 307L's or something very similar and are not that expensive.

It's just what I like to call cheap insurance. Insurance from you having to do this again anytime soon. Hence the recommendation for the other parts as well. Seals at a minimum.

Good luck.

Hopefully someone with a better eye (or two?) can see something easy, but it's not looking good at this point.

Paul