clinem03

Full Member

- Joined

- Sep 9, 2017

- Messages

- 400

Specs - Stock 302 and 3 speed Transmission and T-case (j Shifter) on a 76 Wagon.

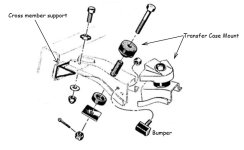

I recently pulled my Transmission to have it rebuilt and am planning to reinstall it myself. Figured i'd kick off a discussion to see if anyone has any good tips on getting it back in? It was a project to get it out, but splitting up the trans and t-case made it a bit easier. The biggest challenge I had was getting the support bar under the transmission/t-case off and then lowering it all down. If I dropped it straight down on the transmission jack with the support bar on, it wouldn't clear my dual exhaust pipes. My plan to get it back in is to have the transmission and t-case strapped down on my transmission jack as a single unit, then loosely bolt one side of the support bar to the transmission, so I can swing the other side around to clear the exhaust pipes then swing it back around to get it to rest on the two mounts on the frame, then slide the whole trans forward into place.

What am I missing? Any ideas/tips to help make this an easier project? Any tips on getting the J shifter into position?

I recently pulled my Transmission to have it rebuilt and am planning to reinstall it myself. Figured i'd kick off a discussion to see if anyone has any good tips on getting it back in? It was a project to get it out, but splitting up the trans and t-case made it a bit easier. The biggest challenge I had was getting the support bar under the transmission/t-case off and then lowering it all down. If I dropped it straight down on the transmission jack with the support bar on, it wouldn't clear my dual exhaust pipes. My plan to get it back in is to have the transmission and t-case strapped down on my transmission jack as a single unit, then loosely bolt one side of the support bar to the transmission, so I can swing the other side around to clear the exhaust pipes then swing it back around to get it to rest on the two mounts on the frame, then slide the whole trans forward into place.

What am I missing? Any ideas/tips to help make this an easier project? Any tips on getting the J shifter into position?