Hello gentlemen!

My name is Jamie

I am building a custom Ford Ranger using s 2000 Explorer 302, Terminator X and the stock waste spark coil packs

This thread is awesome!!

I find myself in a similar situation

We have everything ready to go and the engine is cranking cranking cranking no fire.

It stumbles at times, before the crank sensor LED goes red

I do get some backfires

Setup is Holley term X with COP ignition harness running two 4 channel Holley coil drivers into the stock Explorer 5.0 coil packs

I have explorer 3 wire cam sensor

I am still using the 2 wire crank sensor (for now)

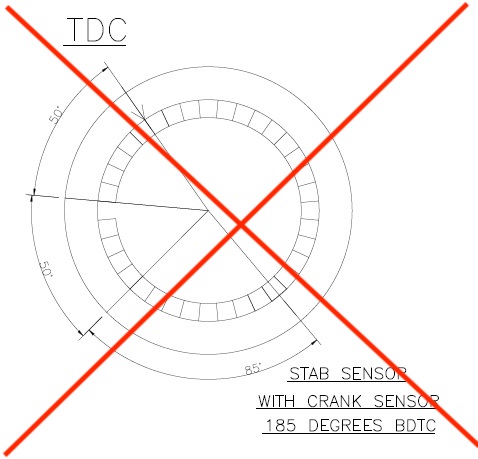

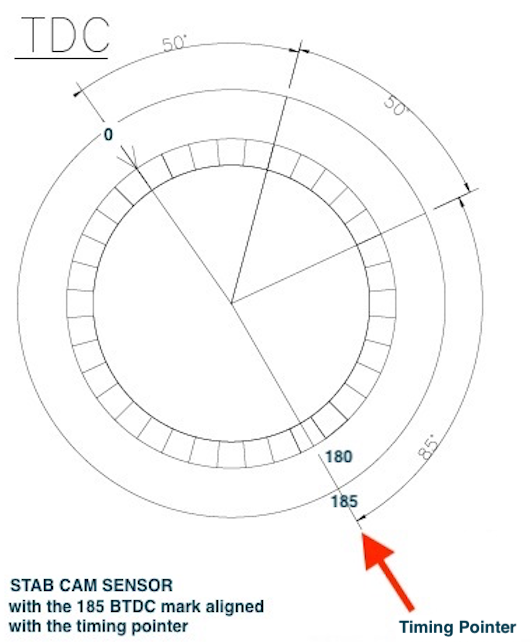

The cam sensor has been stabbed 185 out

I have fuel pressure at rail

Ford IAC is programmed for PWM wire has been assigned and it is working well

All systems are go, but still no fire

We tried 10 different global files we created yesterday, making progress. I have learned ALOT in a short amount of time (normal for me)

I have 30 years of building these trucks and MANY drivetrain conversions under my belt, I am a wiring guy

Which brings me here

I have one question to get us started, this is for

@yakelys69

THANK YOU FOR POSTING ALL THIS INFO! It has been very helpful

In your coil pack wiring you only used the holley coil signal wires for coils 1, 3, 7 and 2?

Why?

Let me elaborate, what I mean is, not why did you do it this way? I understand the ford coil packs only have 4 coils/4 inputs.

I am just wondering if I am missing some info from Holley as to why you chose those wires?

Thinking of changing my setup to match yours

I have my coils combined for the waste spark,

meaning Ford Coil packs fire cyl 1 and 6 at the same time, so I combined the Holley coil signal wires for cyl 1 and 6

after the coil driver into the ford coil pack

I'm just curious if I need to change it to the way you have it setup!

Today I have a few more tricks to try, I am going to change where power for the cam sensor is coming from and I am going to make sure my crank sensor is well shielded. Then we will try again, hoping to hear this engine run today!

My ears are open to any ideas you guys may have!!

This 07 Ranger build can be found at Explorerforum, where I am a moderator.