Community

Message Forum

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Buy / Sell

Bronco Tech

3 Arm Wiper Setup

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Install the app

-

Welcome to ClassicBroncos! - You are currently viewing the forums as a GUEST. To take advantage of all the site features, please take a moment to register. It's fast, simple and absolutely free. So please join our community today!If you have problems registering or can't log into your account, please contact Admin.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ford 9” axle shaft snapped

- Thread starter CopperBronco

- Start date

- Joined

- Nov 3, 2003

- Messages

- 48,105

When you put the new stuff in, including the new seals, make sure all the surfaces are clean and smooth.

Of course, a new axle will be smooth, but it might also have some coatings that have captured some grit. Makes cleaning it beforehand with some light solvent or just some oil or whatever you have around, a generally good practice.

With almost any new part!

And if the area surrounding the seal show any signs of abuse, such as nicks and even light scratches, add a tiny layer of silicone sealer around the perimeter of the new seal.

The seals usually come with some already adhered to the outside shell, but a little insurance from doing it again is a good practice too.

You should not need it, but you never know. I didn't think mine needed it and it leaked! In my case I did not remove the seal and put a new one in, I simply cleaned it off and applied a bead of silicone sealer around the edge.

Worked like a champ after that.

Always apply a tiny bit of oil to the axle shaft before you install it too, to give things a chance to slide and spin freely as they pass over the new seal.

You can apply it to the seal, or the axle shaft. Your choice, but even if I put it on the seal I still put a little on the shaft where the seal runs on it.

Paul

Of course, a new axle will be smooth, but it might also have some coatings that have captured some grit. Makes cleaning it beforehand with some light solvent or just some oil or whatever you have around, a generally good practice.

With almost any new part!

And if the area surrounding the seal show any signs of abuse, such as nicks and even light scratches, add a tiny layer of silicone sealer around the perimeter of the new seal.

The seals usually come with some already adhered to the outside shell, but a little insurance from doing it again is a good practice too.

You should not need it, but you never know. I didn't think mine needed it and it leaked! In my case I did not remove the seal and put a new one in, I simply cleaned it off and applied a bead of silicone sealer around the edge.

Worked like a champ after that.

Always apply a tiny bit of oil to the axle shaft before you install it too, to give things a chance to slide and spin freely as they pass over the new seal.

You can apply it to the seal, or the axle shaft. Your choice, but even if I put it on the seal I still put a little on the shaft where the seal runs on it.

Paul

CopperBronco

Jr. Member

- Joined

- Aug 13, 2021

- Messages

- 379

Thanks! What kind of silicone sealer? And what kind of bearing grease? Mine was quite dirty and rusty… was planning to clean out. Any cleaners recommended? Also how often do you grease front bearings? Would love both a mileage and/or time frame.

Attachments

Last edited:

Hi, you are lucky the broken axle came right out. Usually they need some persuasion. You can use the brake drum on the other side. Put it on the hub, drum side out, and thread 3 lug nuts on by just a couple of turns. The drum will give you a slide hammer action when you push it in and give it a good pull to work the axle out. It is the bearing holding it in. You don't have to remove the backing plate. Good luck

Last edited:

- Joined

- Nov 3, 2003

- Messages

- 48,105

Any old RTV will work.

Whatever you like and have laying around the house usually is fine. It’s not a high-pressure situation.

Just let it cure completely before filling the diff. with oil.

With stock replacements you don’t use bearing grease for the rear. It’s a sealed and “lubed for life” bearing. And depending upon where you buy the axle the bearing is probably already installed. Ready to go basically.

The front does use a high temperature disc brake bearing grease of any decent quality and manufacture.

I typically pay the extra for a good brand of synthetic or semi synthetic water resistant type.

Even trailer wheel bearing grease is a pretty good option for water resistance. Just as long as it’s got a good high temperature rating.

Rolling down the highway is one thing, but the brakes really impart a lot of heat into the bearings and other components.

Whatever you like and have laying around the house usually is fine. It’s not a high-pressure situation.

Just let it cure completely before filling the diff. with oil.

With stock replacements you don’t use bearing grease for the rear. It’s a sealed and “lubed for life” bearing. And depending upon where you buy the axle the bearing is probably already installed. Ready to go basically.

The front does use a high temperature disc brake bearing grease of any decent quality and manufacture.

I typically pay the extra for a good brand of synthetic or semi synthetic water resistant type.

Even trailer wheel bearing grease is a pretty good option for water resistance. Just as long as it’s got a good high temperature rating.

Rolling down the highway is one thing, but the brakes really impart a lot of heat into the bearings and other components.

Rustytruck

Bronco Guru

- Joined

- Feb 24, 2002

- Messages

- 10,875

50 years of stress failed at a stress riser your lucky it lasted that long. lucky it didn't take out the rear quarter panel. You probably have the small bearing on top to help you along. allot better steel available now than back in 1966.

I had exactly this happen to me many years ago. Except I was going about 65 down highway 93 outside Ely Nevada. Quite a job to get it to stop upright on all 3, after I saw the rear wheel pass the truck.

The backstory is that some hundreds of miles earlier, the wheel bearing had expired outside Whitefish Montana at a very bad time and in the middle of nowhere, before cell phones were invented. I was forced to drive about a hundred miles on the bad bearing and smoked it pretty good to get to Whitefish.

The local auto parts store havd no trouble pressing a new bearing, but apparently the damage had been done.

Finding a replacement axle in Ely Nevada in the 1980s was no small task!

Here's the thing though, in the decades since I replaced the axle, that wheel bearing has gone bad on a regular basis. I can only surmise that not only did I damage the axle but I also enlarged the bearing seat, when I smoked the wheel bearing.

I'm happy to report that this year I have replaced the entire housing with Wild Horses brand new, and I put in two new 31 spline axles with the tapered bearings that have the built-in oil seal. It is so much Superior a setup to factory, I can't believe I haven't done it sooner.

Needless to say, I recommend new housing, axles, and disc brakes, and you won't have to worry about this happening ever again.

JB

The backstory is that some hundreds of miles earlier, the wheel bearing had expired outside Whitefish Montana at a very bad time and in the middle of nowhere, before cell phones were invented. I was forced to drive about a hundred miles on the bad bearing and smoked it pretty good to get to Whitefish.

The local auto parts store havd no trouble pressing a new bearing, but apparently the damage had been done.

Finding a replacement axle in Ely Nevada in the 1980s was no small task!

Here's the thing though, in the decades since I replaced the axle, that wheel bearing has gone bad on a regular basis. I can only surmise that not only did I damage the axle but I also enlarged the bearing seat, when I smoked the wheel bearing.

I'm happy to report that this year I have replaced the entire housing with Wild Horses brand new, and I put in two new 31 spline axles with the tapered bearings that have the built-in oil seal. It is so much Superior a setup to factory, I can't believe I haven't done it sooner.

Needless to say, I recommend new housing, axles, and disc brakes, and you won't have to worry about this happening ever again.

JB

CopperBronco

Jr. Member

- Joined

- Aug 13, 2021

- Messages

- 379

Thanks! Great story, I grew up in Twin Falls, I know Ely Nevada quite well. I didn’t smoke anything out… so hoping that’s not the issue and housing isn’t warped… went with the new stronger alloy 28 spline replacement for now. I did tempt a whole new rear end with disc brakes… The only thing that looked damaged when I pulled axle shaft was the inner rubber seal, everything else looked new…I had exactly this happen to me many years ago. Except I was going about 65 down highway 93 outside Ely Nevada. Quite a job to get it to stop upright on all 3, after I saw the rear wheel pass the truck.

The backstory is that some hundreds of miles earlier, the wheel bearing had expired outside Whitefish Montana at a very bad time and in the middle of nowhere, before cell phones were invented. I was forced to drive about a hundred miles on the bad bearing and smoked it pretty good to get to Whitefish.

The local auto parts store havd no trouble pressing a new bearing, but apparently the damage had been done.

Finding a replacement axle in Ely Nevada in the 1980s was no small task!

Here's the thing though, in the decades since I replaced the axle, that wheel bearing has gone bad on a regular basis. I can only surmise that not only did I damage the axle but I also enlarged the bearing seat, when I smoked the wheel bearing.

I'm happy to report that this year I have replaced the entire housing with Wild Horses brand new, and I put in two new 31 spline axles with the tapered bearings that have the built-in oil seal. It is so much Superior a setup to factory, I can't believe I haven't done it sooner.

Needless to say, I recommend new housing, axles, and disc brakes, and you won't have to worry about this happening ever again.

JB

Last edited:

CopperBronco

Jr. Member

- Joined

- Aug 13, 2021

- Messages

- 379

Actually large bearing… just counting my lucky stars I was barely moving when it happened.50 years of stress failed at a stress riser your lucky it lasted that long. lucky it didn't take out the rear quarter panel. You probably have the small bearing on top to help you along. allot better steel available now than back in 1966.

CopperBronco

Jr. Member

- Joined

- Aug 13, 2021

- Messages

- 379

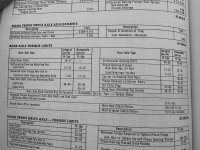

One last question, what is the torque spec on the axle shaft to backer plate/ housing? See photos… I think since I’m large bearing it’s 40 ft/lbs… but that strikes me as not a lot for such an important part… in the chart I think it’s the “rear axle shaft bearing retaining nuts… correct? Help me if I’m wrong.

Attachments

- Joined

- Nov 3, 2003

- Messages

- 48,105

I’ve seen as high as 60, but that was too much for some. 40 is fine for this application.

It doesn’t change the strength of the retainer. The wider spacing of the large bearing is an advantage though.

Wouldn’t hurt to get multiple opinions on the bolt torque, but I think 40 is plenty for what we’re talking about so that sounds right to me.

It doesn’t change the strength of the retainer. The wider spacing of the large bearing is an advantage though.

Wouldn’t hurt to get multiple opinions on the bolt torque, but I think 40 is plenty for what we’re talking about so that sounds right to me.

CopperBronco

Jr. Member

- Joined

- Aug 13, 2021

- Messages

- 379

When you put the shaft, bearing and inner seal in, do you just put oil on the shaft, or a little on the inner seal and bearing as well? I’m assuming you don’t, correct? Also, you said put RTV on inner axle seal, is that before or after you get it in the housing? And for curing the RTV, do I then need to wait 24hrs before putting everything together? I cleaned up the housing…. See photo. Any reco’s on what to put on housing retainer to prevent rust?

Attachments

Last edited:

Every oil seal I install I load up the groves with grease and put a touch of grease on the shaft where the seal is going to ride. It's always served me wellWhen you put the shaft, bearing and inner seal in, do you just put oil on the shaft, or a little on the inner seal and bearing as well? I’m assuming you don’t, correct? Also, you said put RTV on inner axle seal, is that before or after you get it in the housing?

Tim

- Joined

- Nov 3, 2003

- Messages

- 48,105

Me too. Either oil or grease.

Doesn’t matter as long as the surface is lubed a little bit. You are not creating a leak by doing this, you are protecting the rubber from the metal while things are being slid into place.

This is a very long time practice. Goes way back to our grandfathers and probably before.

Doesn’t matter as long as the surface is lubed a little bit. You are not creating a leak by doing this, you are protecting the rubber from the metal while things are being slid into place.

This is a very long time practice. Goes way back to our grandfathers and probably before.

- Joined

- Nov 3, 2003

- Messages

- 48,105

As for the sealer, either way works.

But pressing it in first without additional sealer is easier and cleaner and running a finger bead of sealer around the perimeter after the fact is just as effective.

Letting it cure for whatever time is listed on the package is just good practice to give it a chance to avoid leaking if it’s indeed submerged in a slight bath of lube at the bottom of the tube.

You don’t have to let it cure before installing the axle. Just cure before filling the housing with Carol.

But pressing it in first without additional sealer is easier and cleaner and running a finger bead of sealer around the perimeter after the fact is just as effective.

Letting it cure for whatever time is listed on the package is just good practice to give it a chance to avoid leaking if it’s indeed submerged in a slight bath of lube at the bottom of the tube.

You don’t have to let it cure before installing the axle. Just cure before filling the housing with Carol.

CopperBronco

Jr. Member

- Joined

- Aug 13, 2021

- Messages

- 379

One more question, I got both axle shafts installed, and now have a clicking sound coming from rear when driving at about 10-15 mph… haven’t gone faster yet. Any ideas? It’s coming from the side that didn’t snap I believe. (I replaced both sides). Reminder this is a 66-75 large bearing 9” rear, 11”x2” drums, has spacers and 33” tires. Here’s my guess:

1. Something inside drum is rubbing, or drum against backing plate, etc…

2. Somehow splines in axle shaft are misaligned inside differential.

3. New drum backing plate and housing bolts nuts and washers somehow hitting? Or could I have bumped something on rear drum brakes?

4. Driver side drum was worn more than passenger, I cleaned it up, possible cleaning created clicking due to wear in drum? Wasn’t that bad of a wear though, drum pads replaced in 2017, and barely driven since.

1. Something inside drum is rubbing, or drum against backing plate, etc…

2. Somehow splines in axle shaft are misaligned inside differential.

3. New drum backing plate and housing bolts nuts and washers somehow hitting? Or could I have bumped something on rear drum brakes?

4. Driver side drum was worn more than passenger, I cleaned it up, possible cleaning created clicking due to wear in drum? Wasn’t that bad of a wear though, drum pads replaced in 2017, and barely driven since.

Attachments

-

DC76305C-6A0A-4094-91EE-1B71C052665E.jpeg226.3 KB · Views: 14

DC76305C-6A0A-4094-91EE-1B71C052665E.jpeg226.3 KB · Views: 14 -

395D606C-0C3C-418B-90F5-74F9371F41BE.jpeg243.6 KB · Views: 13

395D606C-0C3C-418B-90F5-74F9371F41BE.jpeg243.6 KB · Views: 13 -

8E21B99F-4E02-4E56-952C-F4A5EB948240.jpeg274.3 KB · Views: 13

8E21B99F-4E02-4E56-952C-F4A5EB948240.jpeg274.3 KB · Views: 13 -

FF264BB9-D8B1-4180-962D-9027D4A28861.jpeg227.8 KB · Views: 11

FF264BB9-D8B1-4180-962D-9027D4A28861.jpeg227.8 KB · Views: 11 -

C641EF48-5B60-44CB-B07C-EB24EF2681CA.jpeg165.6 KB · Views: 11

C641EF48-5B60-44CB-B07C-EB24EF2681CA.jpeg165.6 KB · Views: 11 -

10BC6959-5372-4F01-B1A5-CDFA4C9375EC.jpeg184.4 KB · Views: 15

10BC6959-5372-4F01-B1A5-CDFA4C9375EC.jpeg184.4 KB · Views: 15

CopperBronco

Jr. Member

- Joined

- Aug 13, 2021

- Messages

- 379

Worth saying clicking sound is only above certain low speed, and not a harsh sound. Just slight sound I have to pay attention to. Possible I’m hyper alert after wheel coming off down the road, but also new at this and don’t want to do something dumb.

- Joined

- Jan 9, 2010

- Messages

- 361

Zip tie on the driveshaft? Haha, I'm sure it's not it, but it has always been a favorite of mine when a buddy isn't looking...

Broncobowsher

Total hack

- Joined

- Jun 4, 2002

- Messages

- 35,126

Wheel on tight? I've had the lugnuts bottom out and be tight, but the wheel was still loose.

- Joined

- Jul 5, 2009

- Messages

- 1,781

This may not be it, but I replaced my axles with HD ones and the passenger side was about 1/8" too long. Curious if you have one that is slightly too long and it is creating some contact somewhere. Might only hear it when you are turning though.

Similar threads

- Replies

- 0

- Views

- 551

City: North Pekin

Price: $30

- Replies

- 4

- Views

- 354

City: COSTA MESA

Price: $30

- Replies

- 1

- Views

- 204

City: North Pekin

Price: $500

- Replies

- 2

- Views

- 553