Be careful, if you engineer something that will fit many of our trucks then many of us will bug you with order requests until you give in and make me a sexy battery box. I have a press brake so maybe I should got on board and do it myself. But bugging you is easier.

Community

Message Forum

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Buy / Sell

Bronco Tech

3 Arm Wiper Setup

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Install the app

-

Welcome to ClassicBroncos! - You are currently viewing the forums as a GUEST. To take advantage of all the site features, please take a moment to register. It's fast, simple and absolutely free. So please join our community today!If you have problems registering or can't log into your account, please contact Admin.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OBD II Engine/Transmission Swap - The Next Generation

- Thread starter Dave

- Start date

- Joined

- Aug 25, 2006

- Messages

- 2,245

Completed the induction system

I did a little machine work and cleaned up the transitions in the air intake. I still have to make a bracket for the throttle cable. I have to turn the throttle body upside down putting the idle control valve on the bottom. Since its only clean air I can't see any problems with it working on the bottom. Maybe moisture?? The airflow whould be an improvement over stock as two 90 degree elbows are now two 45 degree angles. I'm having to deviate from my origional goal of keeping the motor in its bone stock configuration to make it fit uder the stock hood and minimal body lift.

Running out of components to mount so the tub will be comming back off for interior (cab and engine compartment) paint. I'll set up the axles, drive shafts, suspension, brake lines, fuel lines, ans some wiring before the tub goes back on.

Things should start progressing pretty fast from here on. Still hoping to have it on the road this summer.

I did a little machine work and cleaned up the transitions in the air intake. I still have to make a bracket for the throttle cable. I have to turn the throttle body upside down putting the idle control valve on the bottom. Since its only clean air I can't see any problems with it working on the bottom. Maybe moisture?? The airflow whould be an improvement over stock as two 90 degree elbows are now two 45 degree angles. I'm having to deviate from my origional goal of keeping the motor in its bone stock configuration to make it fit uder the stock hood and minimal body lift.

Running out of components to mount so the tub will be comming back off for interior (cab and engine compartment) paint. I'll set up the axles, drive shafts, suspension, brake lines, fuel lines, ans some wiring before the tub goes back on.

Things should start progressing pretty fast from here on. Still hoping to have it on the road this summer.

Attachments

Last edited:

Tito

CB Fire Starter

Man I wish I lived closer, I'd be at your house being your beer bitch to soak up this knowledge!

Tito

CB Fire Starter

How are the explorer exhaust manifolds fitting? Will they work or do you need to modify them? I am installing another explorer motor here in another month and am wondering if I can use the explorer manifolds with the install.

- Joined

- Aug 25, 2006

- Messages

- 2,245

How are the explorer exhaust manifolds fitting? Will they work or do you need to modify them? I am installing another explorer motor here in another month and am wondering if I can use the explorer manifolds with the install.

The drivers side clears everything nicely if you are using the explorer oil pan and a cross over pipe. The Explorer oil pan seems to be a real nice fit for the front differential. The passenger side is pretty close to stock bronco location. There is about 1/2 inch between the flange and the inner fender well.

Attachments

Tito

CB Fire Starter

Excellent. Thanks for the pics. I used the explorer pan on mine, it fit great. Heck I didnt even take the pan or accessories off, just drained, refilled the fluids and put the mustang efi and rjm harness on and fired it up really. I used the Bronco manifolds on mine and just took a grinder to the cast iron to clear room for the plugs and wires but I am out of manifolds. Those explorer manifolds are funky.

- Joined

- Aug 25, 2006

- Messages

- 2,245

Those explorer manifolds are funky.

Yea they are but for a purpose. They're routed so they don't cook the motor mounts. They have been prone to cracks but from my experience its mostly due to loose bolts. They seem to run pretty nice in the Explorer I'm driving so I'll go with them for now. Someday I"ll have a mandrel bender and might make up some headers.

- Joined

- Aug 25, 2006

- Messages

- 2,245

Battery Box

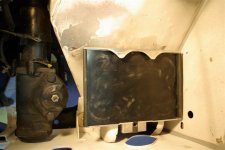

Had to take a couple of weeks off to entertain out of town guests and do a bunch of skiing. Completed the battery box today and fit it up. I removed one of the body brackets from the passenger side where I mounted the air box. Welded it back in on the drivers side to support the new battery location. It matches up with Explorer wire harness nicely. I made it out of the same 5052 .125 aluminum just for more practice before tackling the gas tank. I'm pretty happy with it. It will get powder coated stain black before final assembly.

Had to take a couple of weeks off to entertain out of town guests and do a bunch of skiing. Completed the battery box today and fit it up. I removed one of the body brackets from the passenger side where I mounted the air box. Welded it back in on the drivers side to support the new battery location. It matches up with Explorer wire harness nicely. I made it out of the same 5052 .125 aluminum just for more practice before tackling the gas tank. I'm pretty happy with it. It will get powder coated stain black before final assembly.

Attachments

-

battery box 015 (Large).jpg51.8 KB · Views: 97

battery box 015 (Large).jpg51.8 KB · Views: 97 -

battery box 012 (Large).jpg63.9 KB · Views: 105

battery box 012 (Large).jpg63.9 KB · Views: 105 -

battery box 010 (Large).jpg80.2 KB · Views: 96

battery box 010 (Large).jpg80.2 KB · Views: 96 -

battery box 009 (Large).jpg69.3 KB · Views: 100

battery box 009 (Large).jpg69.3 KB · Views: 100 -

battery box 008 (Large).jpg64.4 KB · Views: 84

battery box 008 (Large).jpg64.4 KB · Views: 84 -

battery box 007 (Large).jpg54.6 KB · Views: 93

battery box 007 (Large).jpg54.6 KB · Views: 93 -

battery box 004 (Large).jpg70 KB · Views: 105

battery box 004 (Large).jpg70 KB · Views: 105

Very Nice! ;D ;D ;D

I enjoy reading about your progress... Bronco Driver material...

Doug

I enjoy reading about your progress... Bronco Driver material...

Doug

- Joined

- Aug 25, 2006

- Messages

- 2,245

710

The explorer has a nice oil filler. It sticks up too high and hits the hood even with a 1" body lift. I looked for a neat way to shorten it as the bottom necks down to fit in a tube on top of the valve cover. Turns out you can cut off the reduction and it will fit inside the filler tube. Cut the filler tube off an inch or so and weld the reduction back on. I used the TIG as the metal is pretty light but it could be soldered, brazed, or MIGed with care.

I also got a bunch of other stuff located today and am meeting the goal of no modifications to the engine wire harness. Making all this stuff fit under the stock hood is a bit more of a challenge than I expected but its all working out nicely.

The explorer has a nice oil filler. It sticks up too high and hits the hood even with a 1" body lift. I looked for a neat way to shorten it as the bottom necks down to fit in a tube on top of the valve cover. Turns out you can cut off the reduction and it will fit inside the filler tube. Cut the filler tube off an inch or so and weld the reduction back on. I used the TIG as the metal is pretty light but it could be soldered, brazed, or MIGed with care.

I also got a bunch of other stuff located today and am meeting the goal of no modifications to the engine wire harness. Making all this stuff fit under the stock hood is a bit more of a challenge than I expected but its all working out nicely.

Attachments

Last edited:

samamarshall

Full Member

- Joined

- Nov 3, 2008

- Messages

- 216

Keep it coming. I'm planning on doing the same thing as you once I find a donor vehicle...and once you're done of course

Hal9000

Bronco Guru

Dave please take a bow. This is an amazing thread and your workmanship and diligence in recording your efforts for the rest of us are not going unappreciated.

I'm still looking for my efi donor, but I guess I may have to expand my search from loose engines to complete wrecked explorers.

I have two questions though....

First; for your Idle control valve, could you have got the clearance you need by must milling down the mounting flange on the throttle body? It looks pretty thick.. Or what about just rotating the TB 90 or 180 degrees?

Second; What's your hourly rate for helping those of us who aren't as technically skilled as you are

I'm still looking for my efi donor, but I guess I may have to expand my search from loose engines to complete wrecked explorers.

I have two questions though....

First; for your Idle control valve, could you have got the clearance you need by must milling down the mounting flange on the throttle body? It looks pretty thick.. Or what about just rotating the TB 90 or 180 degrees?

Second; What's your hourly rate for helping those of us who aren't as technically skilled as you are

Roadburner

Full Member

- Joined

- Mar 14, 2008

- Messages

- 168

Great info Dave. I will have alot of questions to ask you in the near future. I have a 96 AWD explorer that I use for a daily driver. I also used a motor out of one in my bronco. I didn't get the complete harness but got most of it. I used a c4 tranny and d20. Put a high pressure fuel pump in the tank with a return line. I do not have the tank pressure sensor hooked up, The two rear 02 sensors, Any of the tranny wiring, none of the ABS stuff, and cant remember off hand what else isn't hooked up. It fires right up, runs fairly well just doesn't seem to take a full pedal. It boggs down when you floor it,If you keep it half throttle it runs well until you need more on the hills. It also boggs for a split second when it shifts if your in it good. Any ideas as to what kind of resistance reading the rear two 02 sensor should give out. (thinking I can fake them). Is there anything you know about the tranny wiring that i can delete some how? I have the switch hooked up that tells it what gear it is in, just leave it in neutral. Never tried to move it into drive or any other gear for that matter. Another thing is does the d20 bolt right up to the explorer tranny, I want to get rid of the AWD in my DD. Just a few of my questions for now.

- Joined

- Aug 25, 2006

- Messages

- 2,245

Any ideas as to what kind of resistance reading the rear two 02 sensor should give out. (thinking I can fake them). Is there anything you know about the tranny wiring that i can delete some how? I have the switch hooked up that tells it what gear it is in, just leave it in neutral. Never tried to move it into drive or any other gear for that matter. Another thing is does the d20 bolt right up to the explorer tranny, I want to get rid of the AWD in my DD. Just a few of my questions for now.

I'm using the ZF adaptor to bolt the D20 to the 4R70W. It's quite a bit cheaper and you dont have to dissassemble the tranny. The rear O2 sensors only monitor the performance of the cats. Shouldn't effect the way it runs. It will generate codes. The fuel tank pressure sensor is part of the vapor control system which shouldn't effect the way it runs.

I'm running everything in the stock configuration so I really can't answer the question of what components/circuits are necessary.

Attachments

Last edited:

- Joined

- Aug 25, 2006

- Messages

- 2,245

Dave please take a bow. This is an amazing thread and your workmanship and diligence in recording your efforts for the rest of us are not going unappreciated.

I'm still looking for my efi donor, but I guess I may have to expand my search from loose engines to complete wrecked explorers.

I have two questions though....

First; for your Idle control valve, could you have got the clearance you need by must milling down the mounting flange on the throttle body? It looks pretty thick.. Or what about just rotating the TB 90 or 180 degrees?

Second; What's your hourly rate for helping those of us who aren't as technically skilled as you are

Thanks! The idle valve sticks up pretty high. It can be rotated 90 degrees but I liked the way the throttle cable and wire harness hooked up with it on the bottom. If I wasn't set on keeping a stock look and scoop on the hood would make it all easy. I might make another flange with the TB angled a little farther aft and down slightly. That would make everything clear in it stock position and straighten out the air path slightly. That will probably happen after it's on the road.

Look for a 2000 Explorer. It makes the fuel system real simple. (no return line) Also a few other improvements in the engine and tranny.

Hal9000

Bronco Guru

Thanks. I have to admit that my head was spinning by the time I got through the whole thread. But it seemed to me that there might also be some advantage to getting a 97 exploder (none of the anti-theft wiring to deal with, so no headaches trying to manage a clean install for the chip keys and all that, right?) Honestly, what I get will probably depend mostly on what I find. Good enough is good enough and I'm trying not to marry myself to any specific plan yet.

Anyway, for the TB, you might also want to consider a straight, offset adapter that keeps the TB in the stock location, but lowers it 1/2" or 1". Phenolic and micarta are super easy to work with and you could easily make an offset adapter that bolts right to the existing elbow but has the mating flange lowered. That would minimize throttle linkage mods and probably be a very stealthy mod. You could even angle the TB downward to get a little more clearance if needed.

Just an idea....

Anyway, for the TB, you might also want to consider a straight, offset adapter that keeps the TB in the stock location, but lowers it 1/2" or 1". Phenolic and micarta are super easy to work with and you could easily make an offset adapter that bolts right to the existing elbow but has the mating flange lowered. That would minimize throttle linkage mods and probably be a very stealthy mod. You could even angle the TB downward to get a little more clearance if needed.

Just an idea....

- Joined

- Aug 25, 2006

- Messages

- 2,245

Thanks. I have to admit that my head was spinning by the time I got through the whole thread. But it seemed to me that there might also be some advantage to getting a 97 exploder (none of the anti-theft wiring to deal with, so no headaches trying to manage a clean install for the chip keys and all that, right?) Honestly, what I get will probably depend mostly on what I find. Good enough is good enough and I'm trying not to marry myself to any specific plan yet.

Anyway, for the TB, you might also want to consider a straight, offset adapter that keeps the TB in the stock location, but lowers it 1/2" or 1". Phenolic and micarta are super easy to work with and you could easily make an offset adapter that bolts right to the existing elbow but has the mating flange lowered. That would minimize throttle linkage mods and probably be a very stealthy mod. You could even angle the TB downward to get a little more clearance if needed.

Just an idea....

I think the PATS box is going to be a nice antitheft feature. It's easy to wire in and pretty self contained. I'm going to make a little compartment behind the ashtray door that will have a key slot to hold a blank (or cut) key in the key reader. I'm using the keys from my 98. As long as the key chip is present when the ignition key is turned on it will enable the PCM. I'll also mount the OBD connector below it. I'll use the orional ignition switch and key in the dash to keep the stock look. Try to get your hands on the a whole running explorer. My neighbor just got his 99 rearended and totaled. The insurance company will let him keep it for a $800 salvage value deducted from the settlement. Deals like that seem to be pretty common. I'd grab it but he wants to try to fix it for his son with junk yard parts.

Ooops - just divulged my super secret security system. ;D

one other consideration: Blank Ford transponder keys are about $80 and the dealer, $50 bucks and a parts store, or $20 at a lock smith shop.

Last edited:

- Joined

- Aug 25, 2006

- Messages

- 2,245

Gas Tank

I've been working on my Tig welding. Trying to to get to the consistant results I want before tackeling my tank. I'm using .125" 5052 aluminum which I've been told is the alloy of choice for fuel tanks in race cars and airplanes. It's tough stuff, bends without stress fractures, welds pretty well, and galls up cutting bits if you try to machine it. I've been working on some projects like my airbox and battery mount to work on my technique. I just built up a fuel tank for my dad. He is restoring an open crankshaft United stationary engine that my grandpa used on the farm to drive a corn chopper and buzz saw. It came out pretty well but I think I'm going to weld up another practice project before the Bronco tank. I'm going to powder coat along with some other parts next week. We need a new mailbox so...

Here are a few things I learned: The plazma cutter makes beautiful cuts but the edge has becomes deeply embeded with oxide which contaminates the weld. It has to be ground back. I noticed that saw cuts were welding much nicer that the clean looking plazma cuts. Despite advice I was given, I had much better luck with pure tungsten than I did with 2% toriated or ceriated tungsten. It forms a nice ball and gives me a very stable arc. I'm using lapped seams which requires good control of the heat. I'm getting much better results with a gas lense and sticking the tungsten out a bit farther as I can focus and direc the arc to keep a uniform puddle on both the edge and flat surface of the seam. I was having a problem getting the arc to transition from the edge of the metal to the flat surface if I start with gradual heat. If you just punch the peddal then back off you can blast it right where you want. I noticed that the beginning of the weld was a bit hard to get flowing well. Aluminum conducts heat very well so it takes the area a bit to heat up. Preheating the start area with a map gas torch really helps. I think it also drives out any moisture and lets you from a nice puddle right away. When you get to a point where you need to change position, you can stick the rod in the puddle and back off on the heat and the rod will stick right where you need it when you reposition. Keep the gas shield on the weld site and just add heat when you are ready to continue. Worked real well on those round bosses. I also increased my post flow form 6 seconds to 10 seconds which seems to keep the tungsten cleaner from oxidization.

Here are the parameters that are working for me.

Metal: .125" 5052 Aluminum

Filler: ER 5356 3/32"

Pure tungsten 3/32"

.3 sec pre flow

20 Amp hot start

150 amp max

80 Hz

25% ballance

10 sec post flow

Argon 17 Cu Ft/hr #6 gas lense

Any comments or suggestions are very welcome.

Dave...

edit: Powder coated it today. A little more TIG practice today. I'm getting prettier welds by backing off on the heat a bit and using 1/16" rod. I also backed off to 30% ballance which definitly heats up the torch more. Looking for a decent water cooled torch.

I've been working on my Tig welding. Trying to to get to the consistant results I want before tackeling my tank. I'm using .125" 5052 aluminum which I've been told is the alloy of choice for fuel tanks in race cars and airplanes. It's tough stuff, bends without stress fractures, welds pretty well, and galls up cutting bits if you try to machine it. I've been working on some projects like my airbox and battery mount to work on my technique. I just built up a fuel tank for my dad. He is restoring an open crankshaft United stationary engine that my grandpa used on the farm to drive a corn chopper and buzz saw. It came out pretty well but I think I'm going to weld up another practice project before the Bronco tank. I'm going to powder coat along with some other parts next week. We need a new mailbox so...

Here are a few things I learned: The plazma cutter makes beautiful cuts but the edge has becomes deeply embeded with oxide which contaminates the weld. It has to be ground back. I noticed that saw cuts were welding much nicer that the clean looking plazma cuts. Despite advice I was given, I had much better luck with pure tungsten than I did with 2% toriated or ceriated tungsten. It forms a nice ball and gives me a very stable arc. I'm using lapped seams which requires good control of the heat. I'm getting much better results with a gas lense and sticking the tungsten out a bit farther as I can focus and direc the arc to keep a uniform puddle on both the edge and flat surface of the seam. I was having a problem getting the arc to transition from the edge of the metal to the flat surface if I start with gradual heat. If you just punch the peddal then back off you can blast it right where you want. I noticed that the beginning of the weld was a bit hard to get flowing well. Aluminum conducts heat very well so it takes the area a bit to heat up. Preheating the start area with a map gas torch really helps. I think it also drives out any moisture and lets you from a nice puddle right away. When you get to a point where you need to change position, you can stick the rod in the puddle and back off on the heat and the rod will stick right where you need it when you reposition. Keep the gas shield on the weld site and just add heat when you are ready to continue. Worked real well on those round bosses. I also increased my post flow form 6 seconds to 10 seconds which seems to keep the tungsten cleaner from oxidization.

Here are the parameters that are working for me.

Metal: .125" 5052 Aluminum

Filler: ER 5356 3/32"

Pure tungsten 3/32"

.3 sec pre flow

20 Amp hot start

150 amp max

80 Hz

25% ballance

10 sec post flow

Argon 17 Cu Ft/hr #6 gas lense

Any comments or suggestions are very welcome.

Dave...

edit: Powder coated it today. A little more TIG practice today. I'm getting prettier welds by backing off on the heat a bit and using 1/16" rod. I also backed off to 30% ballance which definitly heats up the torch more. Looking for a decent water cooled torch.

Attachments

Last edited:

- Joined

- Aug 25, 2006

- Messages

- 2,245

Powder coated the practice tank today. Probably the only 1913 3 1/2 hp United stationary engine with a TIG welded 5052 powder coated fuel tank. I'll take some pictures of it when I go back to Michigan in a couple of weeks.

Tonight I'll powder coat some of the Bronco parts and starting work on the real tank tomorrow.

Tonight I'll powder coat some of the Bronco parts and starting work on the real tank tomorrow.

Last edited:

Similar threads

- Replies

- 3

- Views

- 732