gunnibronco

Sr. Member

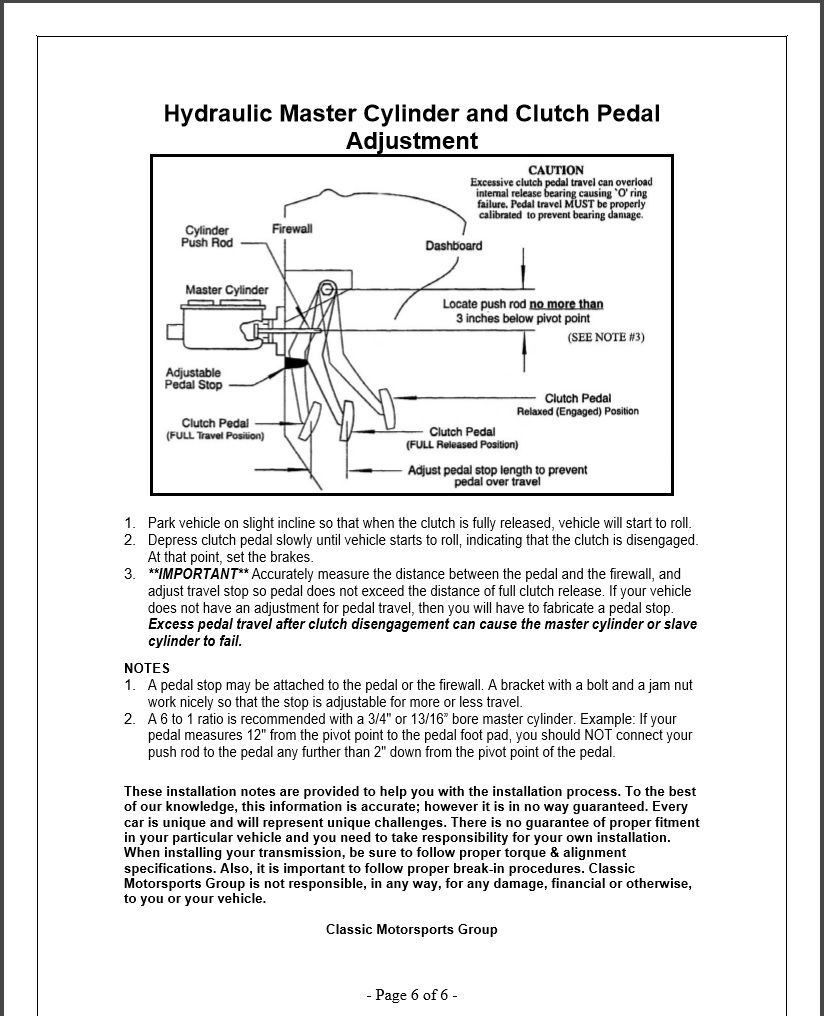

Here is a tech article from Hurst about hydraulic clutches that recommends a stop.

http://www.hurst-drivelines.com/files/Clutch_Linkage_Installation_Tips.pdf

I welded a simple piece of angle iron with a nut/bolt to the pedal near the old mechanical linkage hole. The bolt head hits the cowl above the pedal and will give you some adjustment. I haven't run mine yet, but I've bled the slave cylinder and everything seems to work ok. I haven't made any adjustments yet.

http://www.hurst-drivelines.com/files/Clutch_Linkage_Installation_Tips.pdf

I welded a simple piece of angle iron with a nut/bolt to the pedal near the old mechanical linkage hole. The bolt head hits the cowl above the pedal and will give you some adjustment. I haven't run mine yet, but I've bled the slave cylinder and everything seems to work ok. I haven't made any adjustments yet.

Last edited: