Community

Message Forum

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Buy / Sell

Bronco Tech

3 Arm Wiper Setup

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Install the app

-

Welcome to ClassicBroncos! - You are currently viewing the forums as a GUEST. To take advantage of all the site features, please take a moment to register. It's fast, simple and absolutely free. So please join our community today!If you have problems registering or can't log into your account, please contact Admin.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What have you done to your Bronco today?

- Thread starter Heus33

- Start date

Yes, sir, that’s it! I didn’t know WHAT to call it but good info. Thanks for the answer.@Speedrdr I'm not sure what a CV cover is. Are you taking about the slip yoke boot?

View attachment 935665

Randy

Sad day - end of my Bronco season.

Highlights:

- 9970 miles this season

- replaced cracked distributor cap

- replaced trackbar bushings after noted death wobble

- broke left rear axle - replaced of course

- broken oil sender extension - replaced

- 3-4 trout fishing/camping trips

- too many smiles to calculate

Until the salting ends in the spring...

Peace and Happy Thanksgiving to all!

Highlights:

- 9970 miles this season

- replaced cracked distributor cap

- replaced trackbar bushings after noted death wobble

- broke left rear axle - replaced of course

- broken oil sender extension - replaced

- 3-4 trout fishing/camping trips

- too many smiles to calculate

Until the salting ends in the spring...

Peace and Happy Thanksgiving to all!

Lawndart- SO DANG GLAD the infamous, super tough 9" rear axle didn't cause a bunch of damage or worse!

I am so against running a 50 yr old 9" rear axle in our applications. Car application is a bit different. I have seen SO many Broncos roll from axle breakage. So glad you're ok.

Car's with 9" axle breakage due to bearing failure is so common but they don't roll over due to their stance. They sit on the ground and almost always have a fender that covers the tire in case it walks out and offers some stability until you stop. Cars don't drop 2' off rocks, cars don't try to handle the torque of a V8 on steroids with this drivetrain: bolstered by a 6.72:1 ZF, possibly a doubler at 2.0: 1 additional torque multiplication and then a 4.3:1 Atlas behind that they add in 4.56:1 rear gears but here's what does it... you are running a fully locked rear with 37" tires bouncing on JUST the rear tires trying to make it up over that 2' ledge... torque bends lightweight 9" housings with ease (at times).

Glad you're ok. Guess you can see where I"m coming from! Been preaching this exact issue for 40+ yrs... after I finally realized what was going on back then it still took me forever to step away from them.

I am so against running a 50 yr old 9" rear axle in our applications. Car application is a bit different. I have seen SO many Broncos roll from axle breakage. So glad you're ok.

Car's with 9" axle breakage due to bearing failure is so common but they don't roll over due to their stance. They sit on the ground and almost always have a fender that covers the tire in case it walks out and offers some stability until you stop. Cars don't drop 2' off rocks, cars don't try to handle the torque of a V8 on steroids with this drivetrain: bolstered by a 6.72:1 ZF, possibly a doubler at 2.0: 1 additional torque multiplication and then a 4.3:1 Atlas behind that they add in 4.56:1 rear gears but here's what does it... you are running a fully locked rear with 37" tires bouncing on JUST the rear tires trying to make it up over that 2' ledge... torque bends lightweight 9" housings with ease (at times).

Glad you're ok. Guess you can see where I"m coming from! Been preaching this exact issue for 40+ yrs... after I finally realized what was going on back then it still took me forever to step away from them.

i need to come look at that soft top some time!Sad day - end of my Bronco season.

Highlights:

- 9970 miles this season

- replaced cracked distributor cap

- replaced trackbar bushings after noted death wobble

- broke left rear axle - replaced of course

- broken oil sender extension - replaced

- 3-4 trout fishing/camping trips

- too many smiles to calculate

Until the salting ends in the spring...

Peace and Happy Thanksgiving to all!

- Joined

- Nov 3, 2003

- Messages

- 49,165

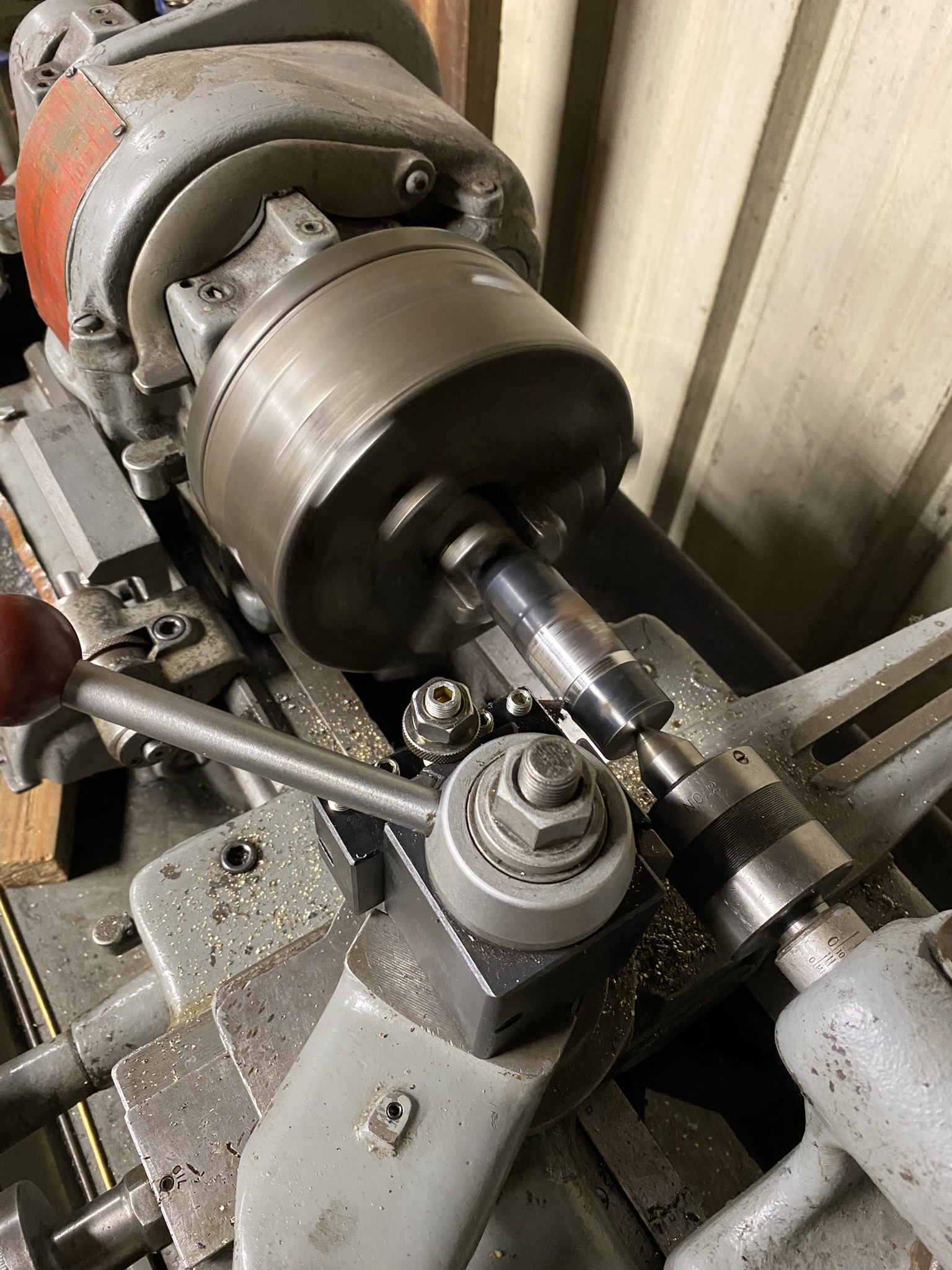

Shiny brake parts are happy brake parts.Oops forgot I added this too... it's so shiny!

What are these spacers of which you both talk about? Spacing the crossmember down a bit I presume?I had to go with a 3/4" spacer with my Tom's crossmember. Your build is looking great.

Paul

Thank you. I had just gotten off the highway doing 65-70 mph for 45 minutes. The axle broke turning left at 10 mph less than a mile from my house. I certainly reflected and pondered a bit on how it could have been.Lawndart- SO DANG GLAD the infamous, super tough 9" rear axle didn't cause a bunch of damage or worse!

Glad you're ok. Guess you can see where I"m coming from! Been preaching this exact issue for 40+ yrs... after I finally realized what was going on back then it still took me forever to step away from them.

Welcome to come by anytime. I am out south of De Soto.i need to come look at that soft top some time!

Hi Paul,Shiny brake parts are happy brake parts.

What are these spacers of which you both talk about? Spacing the crossmember down a bit I presume?

Paul

The spacer I added, is between the crossmember and the transmission tail support.

Attachments

Started exhaust today…finally. Dual exhaust out, 2 in 1 going in.

JeepGuy

Bronco Guru

- Joined

- Aug 24, 2006

- Messages

- 1,253

Been a busy couple week tightening up the little things...

*My 12 year old and I rebuilt the Carb while my 16 year old serviced the spark plugs, drained the oil, changed the filter, and refilled the oil. That was an awesome day.

*Started the Bronco, and to my surprise the rebuild worked. Super rich at the moment but I'll be messing with mixture a bit as we go. Used the good old long line into a mobile gas jug as source. I gotta say, I'm impressed with the manual pumps ability to pull gas. Took maybe 10 seconds to fill the filter and shoot out in all directions from the loose clamp fittings at the carb.

*Added the rear diff shims to account for the pinon angle and lift springs... took some banging around, rigging with straps pulling different directions, some vice clamps, and sledge hammer... but it is done and the pinon looks much happier now.

*Installed extended drive shaft.

*Started the Bronco again just to test my ability to avoid carbon dioxide poisoning while enjoy the thumping sound of American muscle and cold Coors light, and the Star Spangled Banner playing in the background! Turns out about two beers worth of the CO2 is all I can take.

*Re-installed stock gas tank with BRAND NEW fuel pickup/sending unit... only to find a pinhole leak on the BRAND NEW part again... Drained the fuel all over myself bringing the tank down, re-ordered and re-installed BRAND NEW fuel pickup/sending unit. No leaks this time.

*New fuel filler hoses.

*New stainless locking tailgate latch.

*Started the bronco again. Took video next to the tail pipe capturing the sound of a 2 into 1, 2.5 pipe through 2 chamber flow master to all my Jeep buddies with their cute little V6's.

*Tailgate silencer kit with new bump stops... This tail gate on my 74 is now about 100 times tighter than the tailgate on my 04. Can't wait to see if I hear any rattles with it at all.

*New License plate light with new rubber gromets for the wiring. Figured those would give me all kinds of trouble but they were honestly very easy. I guess new rubber vs 50 year rubber makes a difference.

*Finished up the Winters Shifter install, cut the trans cross member, and cycled the gears. Seems to work as expected.

*Started the Bronco again just because.

*Finished drilling all the holes and secured the roll cage completely. The drilling has been killing me as I burn through bits daily. Finally spent more than 2 bucks on a decent set of metal bits and wouldn't you know it... they actually drill through metal...lol

*Finished the frame and diff. mounted Stainless brake line set. I paid extra for the upgraded braided front brake flexible hoses... but the kit was missing the adapter between the hard line and flexible line. That took a half day of driving around trying to find the adapters. Funniest part was at Auto Zone trying to explain to the 20 something person that they just need to bring me their adapter bin and let me have at it. They couldn't get away from year, make, and model... hahahahaha

*Attempted to install steering shaft between IDidIT and 4x4x2 box only to find out the WCB adapter plate I used pushed the box outward just enough to interfere with the inner fender well clearance.

*Cut the clearance hole on the fender....

And now here we are, getting ready to test my sheet metal skills patching the inner fender. We'll see how it goes.

I forget how fun wrenching in the garage can be when parts actually work as designed. Also fun having to figure out the puzzle of these things at times.

*My 12 year old and I rebuilt the Carb while my 16 year old serviced the spark plugs, drained the oil, changed the filter, and refilled the oil. That was an awesome day.

*Started the Bronco, and to my surprise the rebuild worked. Super rich at the moment but I'll be messing with mixture a bit as we go. Used the good old long line into a mobile gas jug as source. I gotta say, I'm impressed with the manual pumps ability to pull gas. Took maybe 10 seconds to fill the filter and shoot out in all directions from the loose clamp fittings at the carb.

*Added the rear diff shims to account for the pinon angle and lift springs... took some banging around, rigging with straps pulling different directions, some vice clamps, and sledge hammer... but it is done and the pinon looks much happier now.

*Installed extended drive shaft.

*Started the Bronco again just to test my ability to avoid carbon dioxide poisoning while enjoy the thumping sound of American muscle and cold Coors light, and the Star Spangled Banner playing in the background! Turns out about two beers worth of the CO2 is all I can take.

*Re-installed stock gas tank with BRAND NEW fuel pickup/sending unit... only to find a pinhole leak on the BRAND NEW part again... Drained the fuel all over myself bringing the tank down, re-ordered and re-installed BRAND NEW fuel pickup/sending unit. No leaks this time.

*New fuel filler hoses.

*New stainless locking tailgate latch.

*Started the bronco again. Took video next to the tail pipe capturing the sound of a 2 into 1, 2.5 pipe through 2 chamber flow master to all my Jeep buddies with their cute little V6's.

*Tailgate silencer kit with new bump stops... This tail gate on my 74 is now about 100 times tighter than the tailgate on my 04. Can't wait to see if I hear any rattles with it at all.

*New License plate light with new rubber gromets for the wiring. Figured those would give me all kinds of trouble but they were honestly very easy. I guess new rubber vs 50 year rubber makes a difference.

*Finished up the Winters Shifter install, cut the trans cross member, and cycled the gears. Seems to work as expected.

*Started the Bronco again just because.

*Finished drilling all the holes and secured the roll cage completely. The drilling has been killing me as I burn through bits daily. Finally spent more than 2 bucks on a decent set of metal bits and wouldn't you know it... they actually drill through metal...lol

*Finished the frame and diff. mounted Stainless brake line set. I paid extra for the upgraded braided front brake flexible hoses... but the kit was missing the adapter between the hard line and flexible line. That took a half day of driving around trying to find the adapters. Funniest part was at Auto Zone trying to explain to the 20 something person that they just need to bring me their adapter bin and let me have at it. They couldn't get away from year, make, and model... hahahahaha

*Attempted to install steering shaft between IDidIT and 4x4x2 box only to find out the WCB adapter plate I used pushed the box outward just enough to interfere with the inner fender well clearance.

*Cut the clearance hole on the fender....

And now here we are, getting ready to test my sheet metal skills patching the inner fender. We'll see how it goes.

I forget how fun wrenching in the garage can be when parts actually work as designed. Also fun having to figure out the puzzle of these things at times.

- Joined

- Nov 24, 2006

- Messages

- 1,233

Following an unusually dry summer and roughly 5000 miles of smiles, our first snow fell on Thanksgiving and so did the road salt.

Today I put the Bronco to bed for hopefully a long winter nap. Sounds crazy I know, but I love to ice fish and snowmobile.

It will be at the 2025 May It Forward (11th annual) with the new WH hydro-boost system that I recently won.

Today I put the Bronco to bed for hopefully a long winter nap. Sounds crazy I know, but I love to ice fish and snowmobile.

It will be at the 2025 May It Forward (11th annual) with the new WH hydro-boost system that I recently won.

Started the engine today. 5-1/2 years since I started this build. has a small exhaust leak on the left bank, but smooth and sounds good otherwise.

Tried to post a video but wouldn't let me due to file type.

Tried to post a video but wouldn't let me due to file type.

New heater core installed and now I have heat!

- Joined

- Feb 26, 2012

- Messages

- 158

Can you post some photos of this?Also got my dash modified to flip down and wired the switches up.

This is the only one I currently have. I made new brackets to be able to space inward and used a 3/8” spacer between the bracket and the kick panel. I’ve seen others that used a bearing, but I will put the original brackets back on once I’m satisfied under the dash.Can you post some photos of this?

abrogate932

Newbie

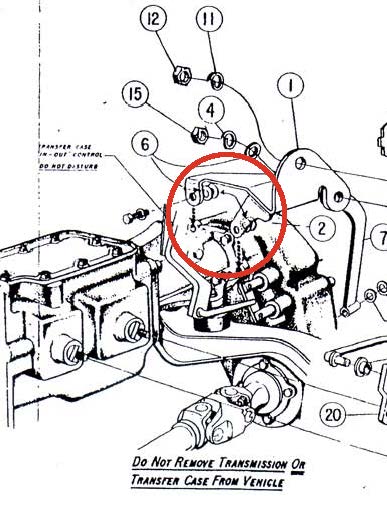

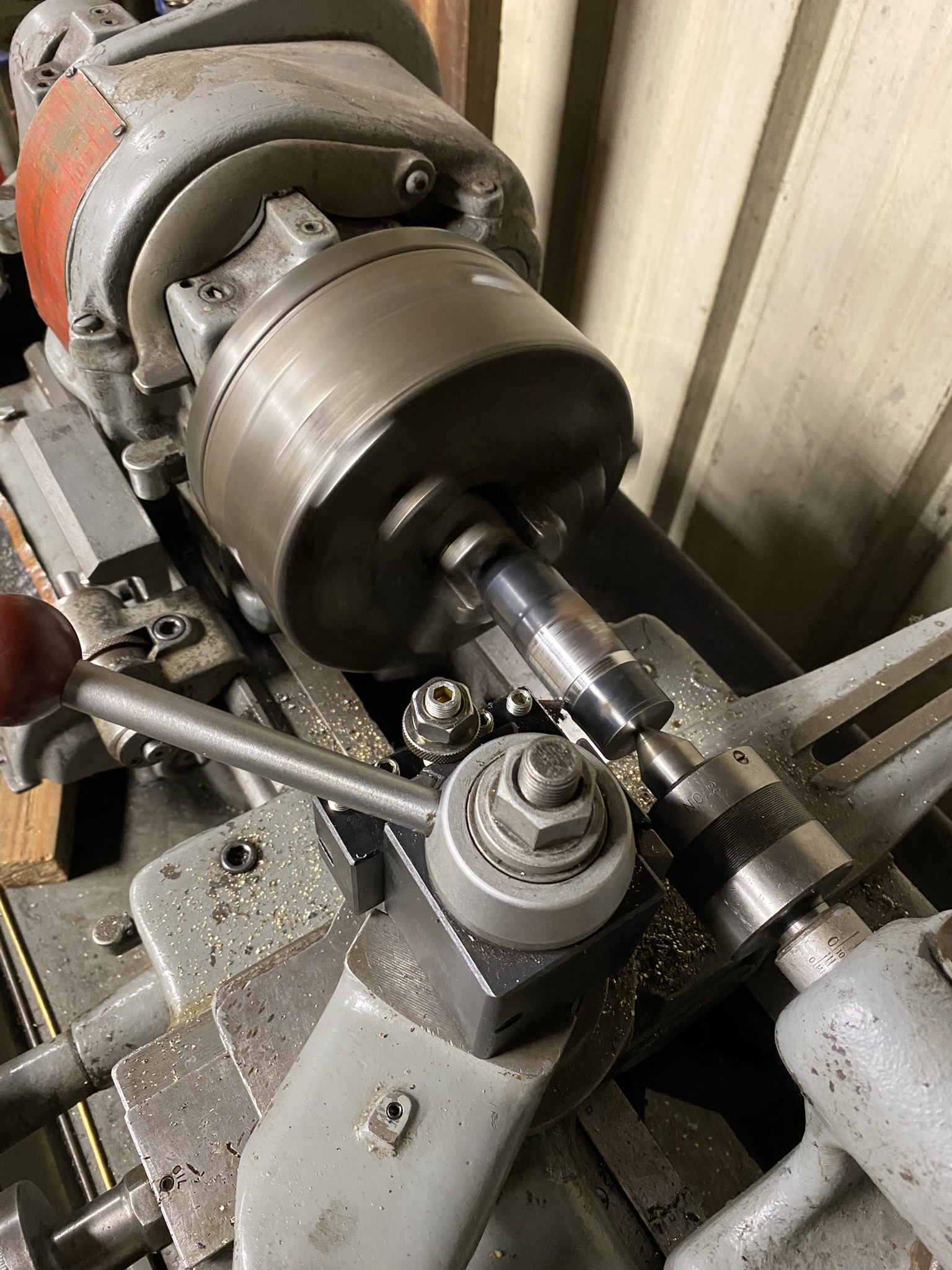

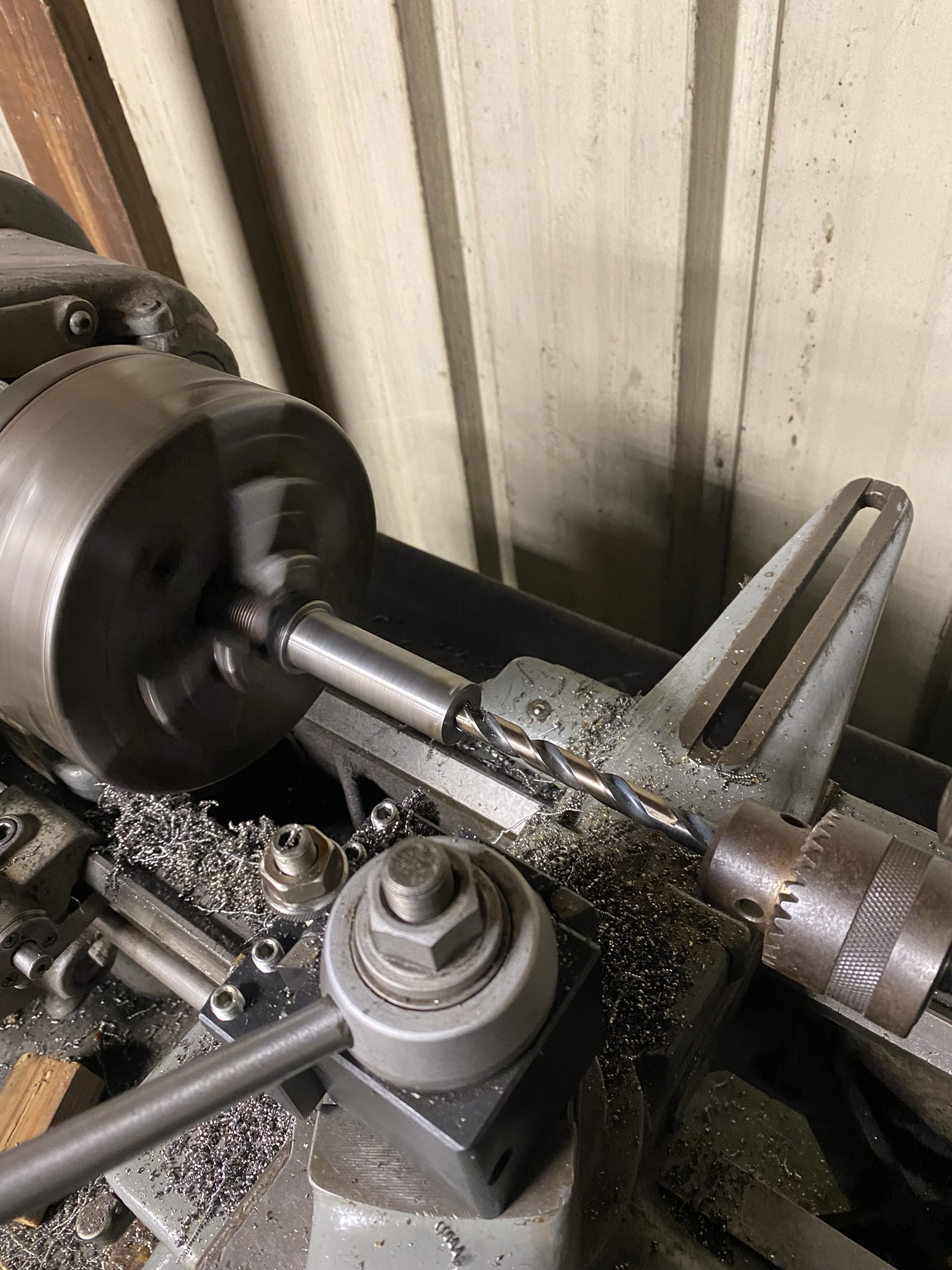

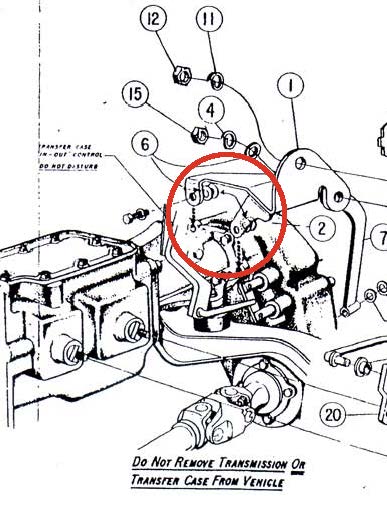

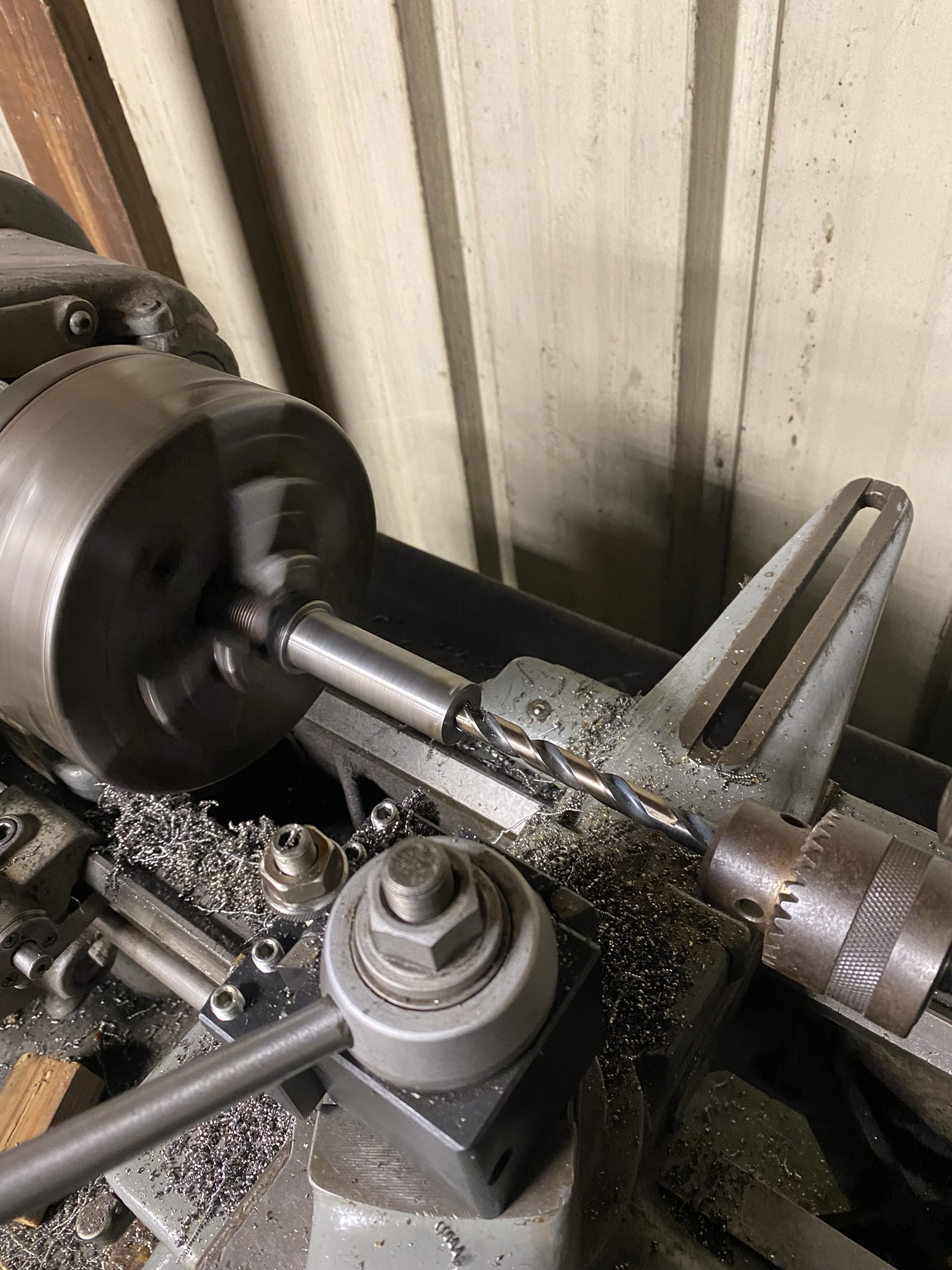

This weekend I was re-installing the Hurst floor shifter on the 3 speed. I don't have a body lift, so I need to install the upper bracket on the Dana 20 after the transmission/transfer case is installed. The two bolts that go through the tail housing adapter require you to stack washers between the bracket and the adapter due to the counter bore/recess on the casting. I have never liked stacking washers so I made some that were the correct thickness. I had a Jeep JK draglink in my scrap pile and decided to recycle it into some custom thickness washers for the application. I coated them with black oxide. They turned out great. Now my Bronco is part Jeep.

I should have TIG tacked them to the bracket, but wasn't sure if there would be assembly issues on the drivers side.

I should have TIG tacked them to the bracket, but wasn't sure if there would be assembly issues on the drivers side.

Finally was able to put the vinyl lettering on my newly painted tailgate, after patiently waiting a month for it to cure. Letter color matches the grille, hardtop, and soon to-be-applied special decor stripe.

Similar threads

- Replies

- 38

- Views

- 6K

- Replies

- 23

- Views

- 4K

- Replies

- 31

- Views

- 1K

- Replies

- 5

- Views

- 676