Digger556

Sr. Member

- Joined

- Aug 8, 2013

- Messages

- 793

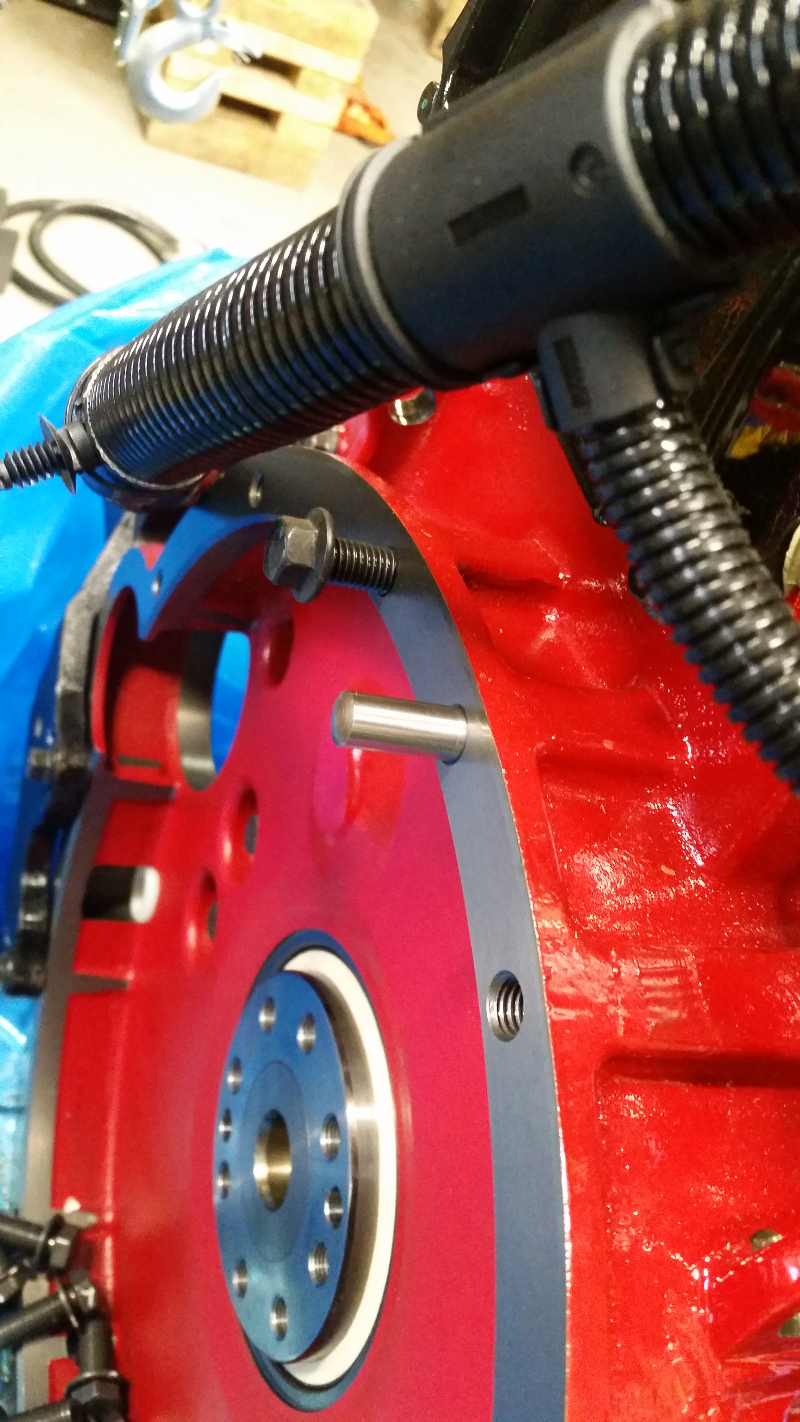

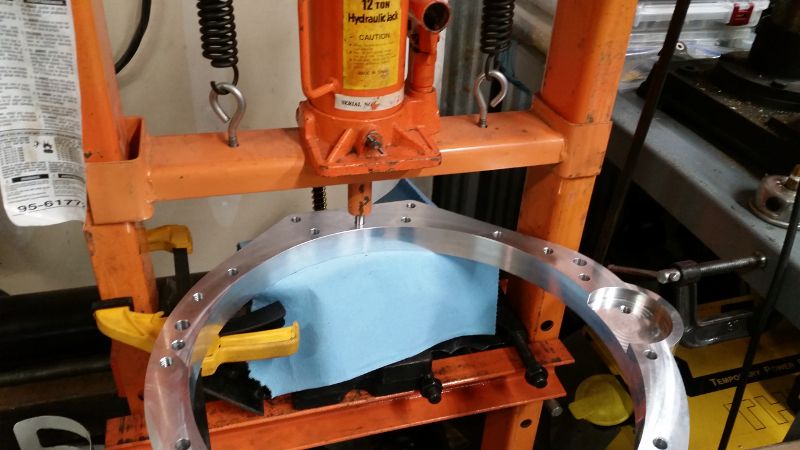

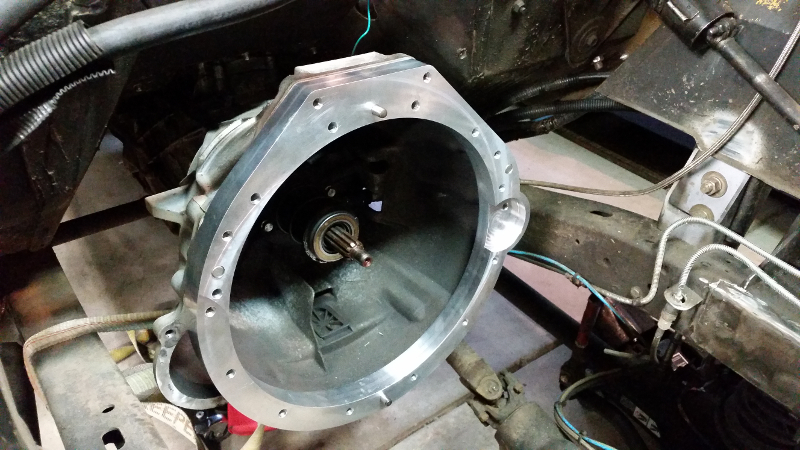

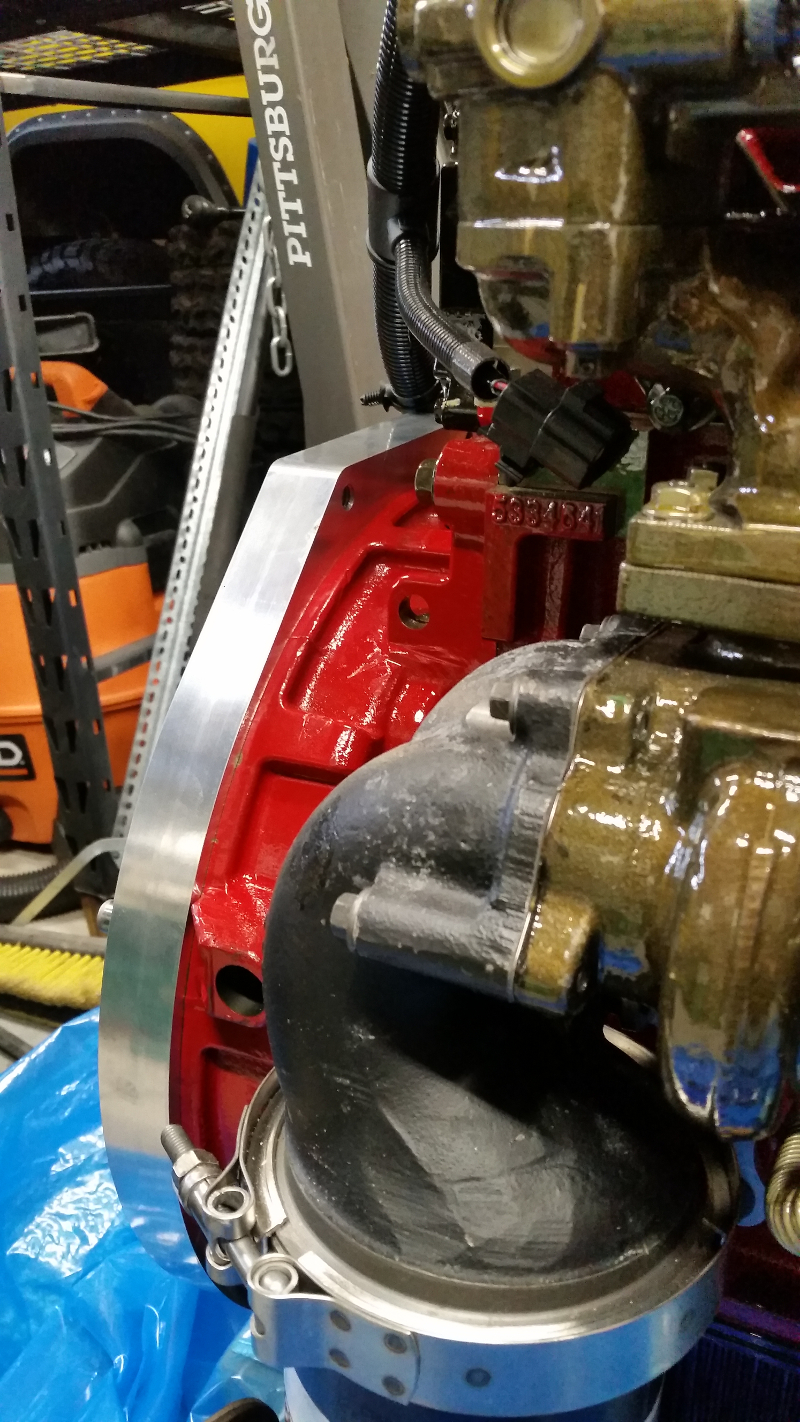

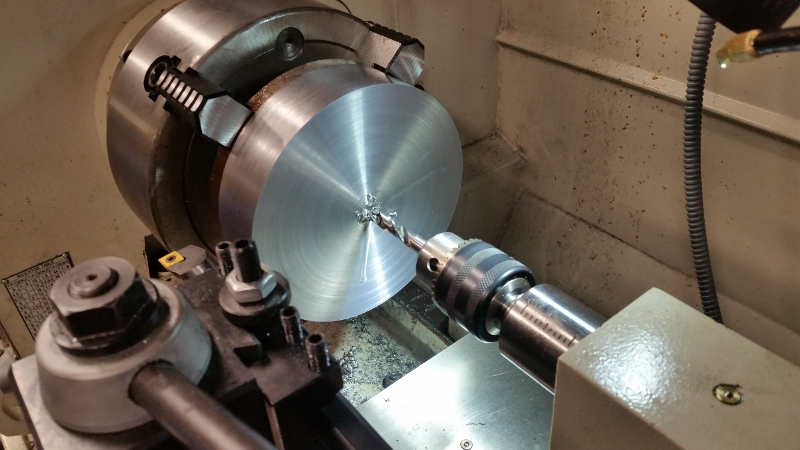

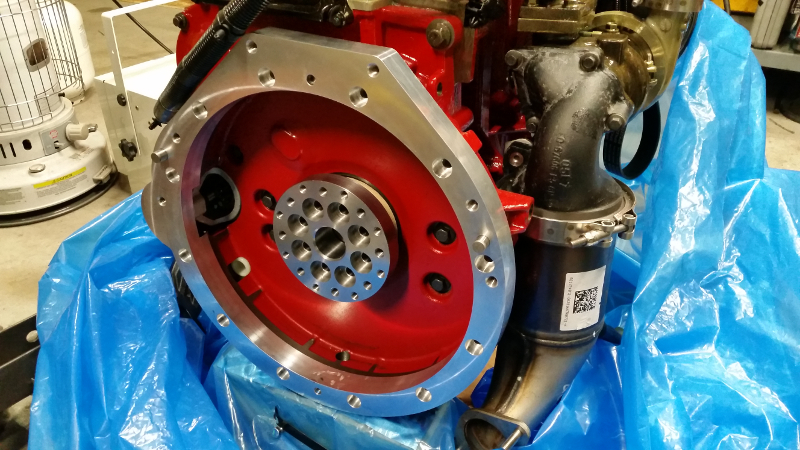

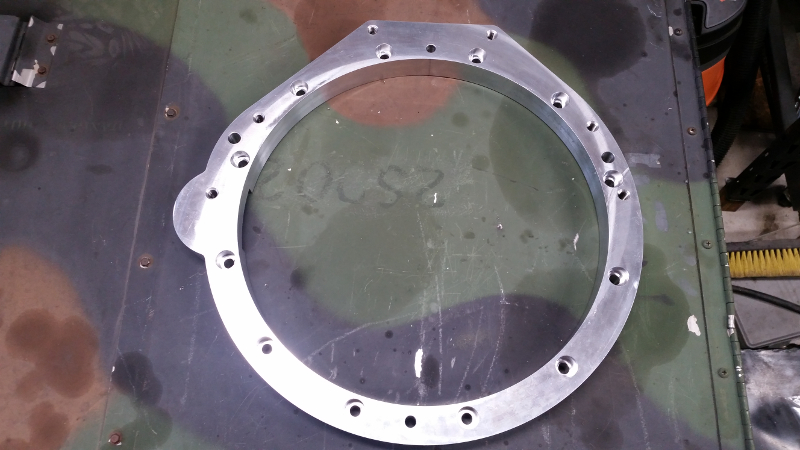

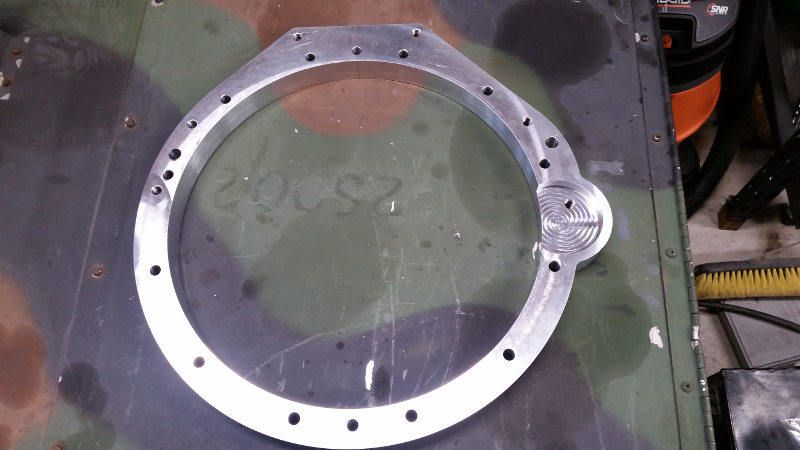

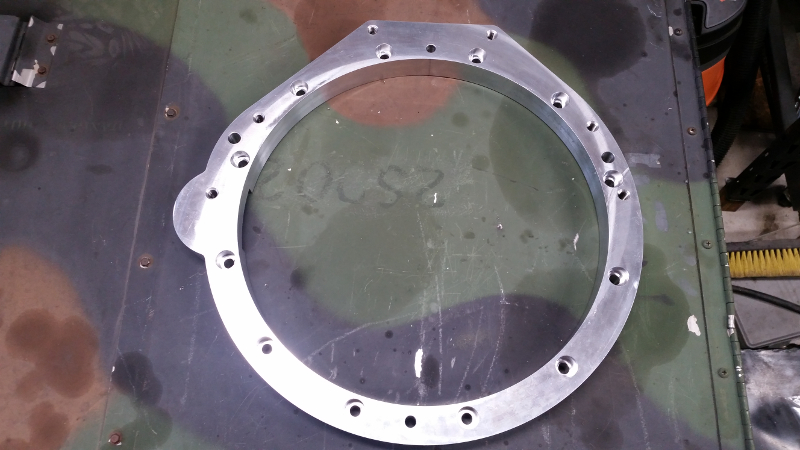

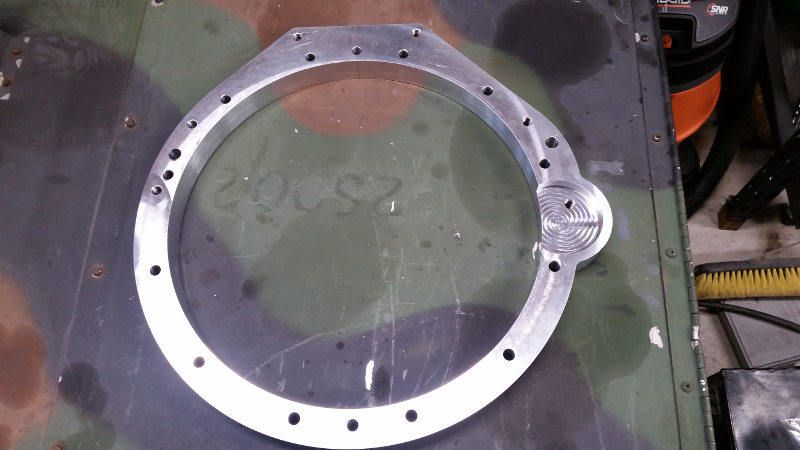

Getting back to the adapter...

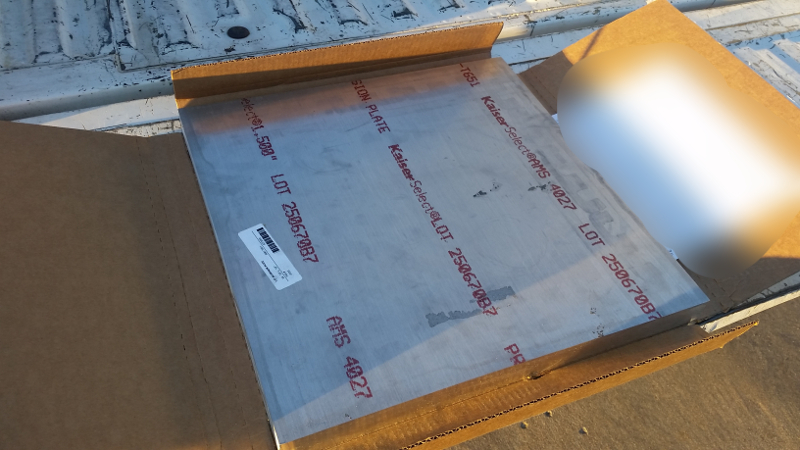

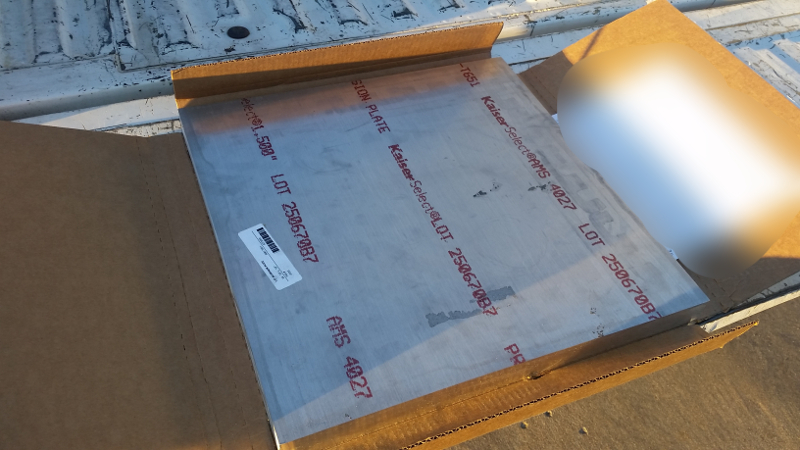

I spoke with our manufacturing engineer at work in order to get a recommendation on a machine shop. (our shop is busy most of the time) He looked at my project and thought we could fit it into the schedule, so we had some back and forth discussing how to produce my bell housing adapter, what machine should run it, who would program it and what was critical. I went ahead and purchased the raw material, a 50lb slab of 6061-T651 aluminum plate that measured 18"x18"x1.5"

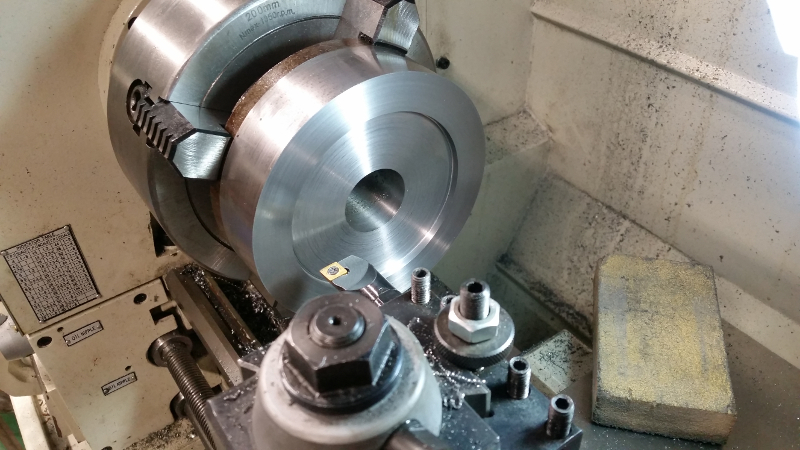

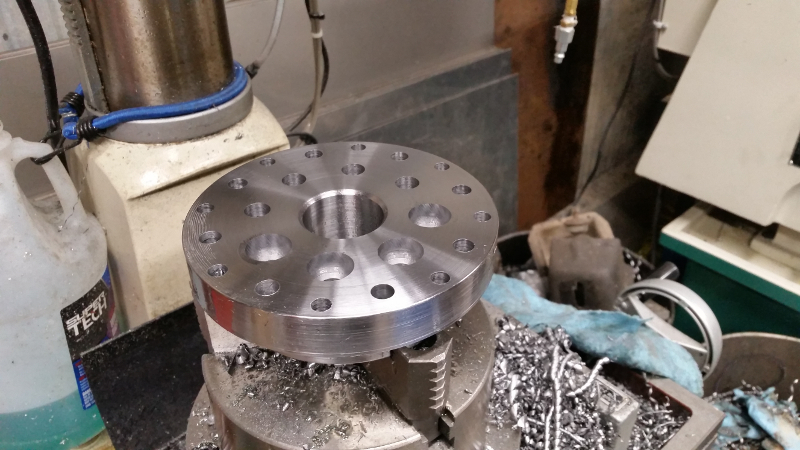

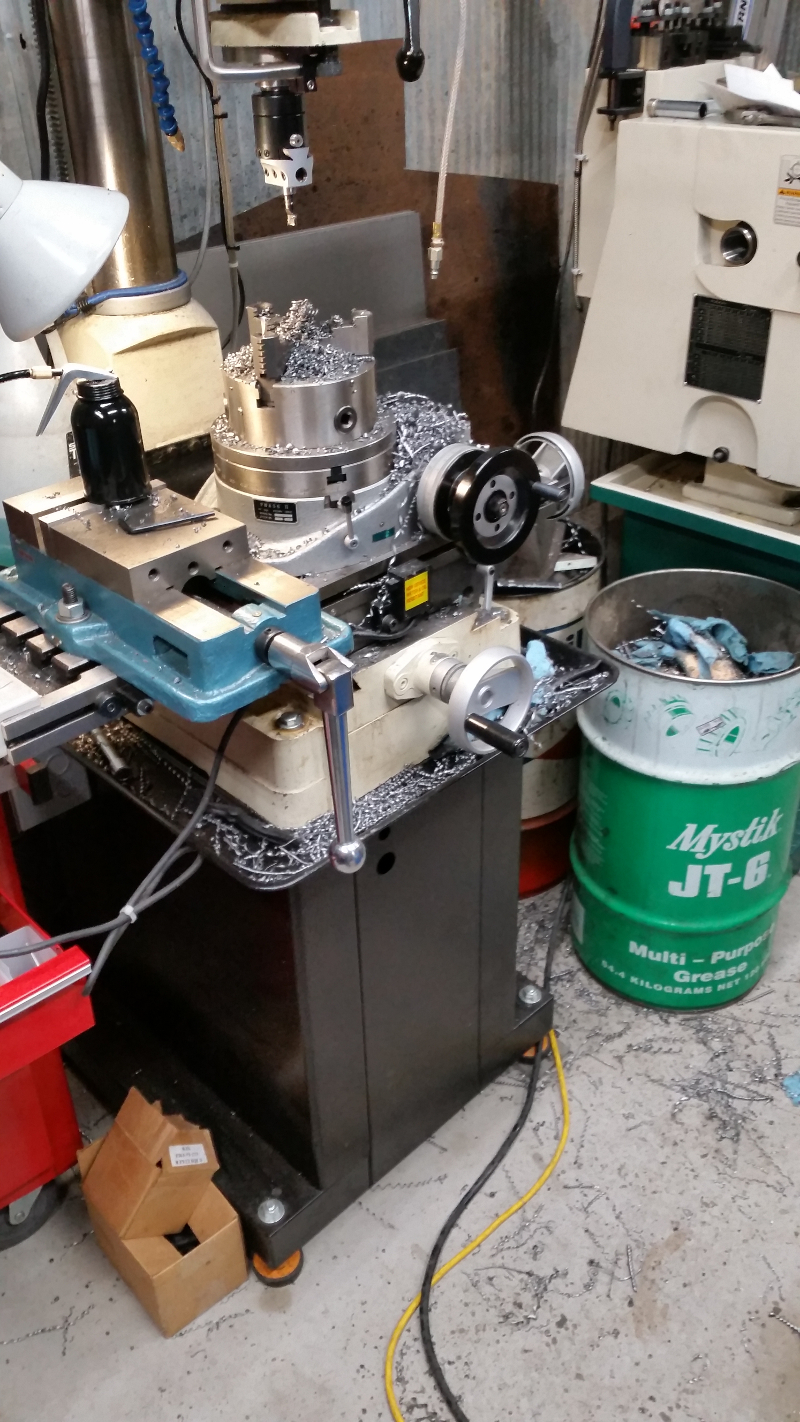

After about 4 weeks, it was time to run my part. The guys really did a great job. It was run in a horizontal mill with a pallet changer and a 35HP spindle. It made short work of my plate.

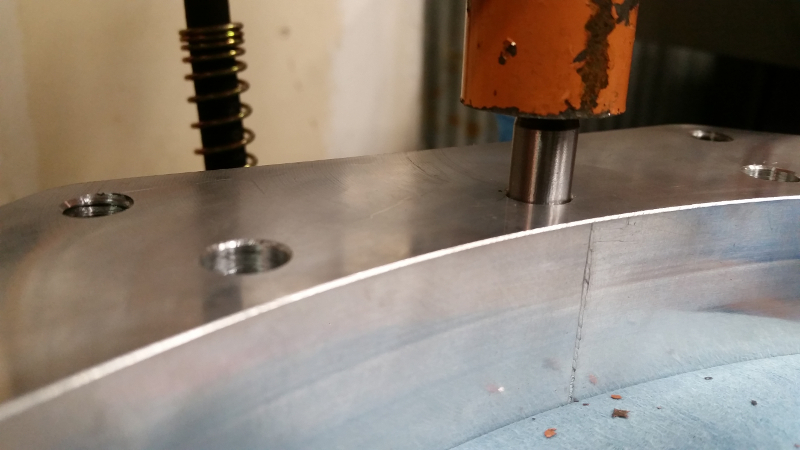

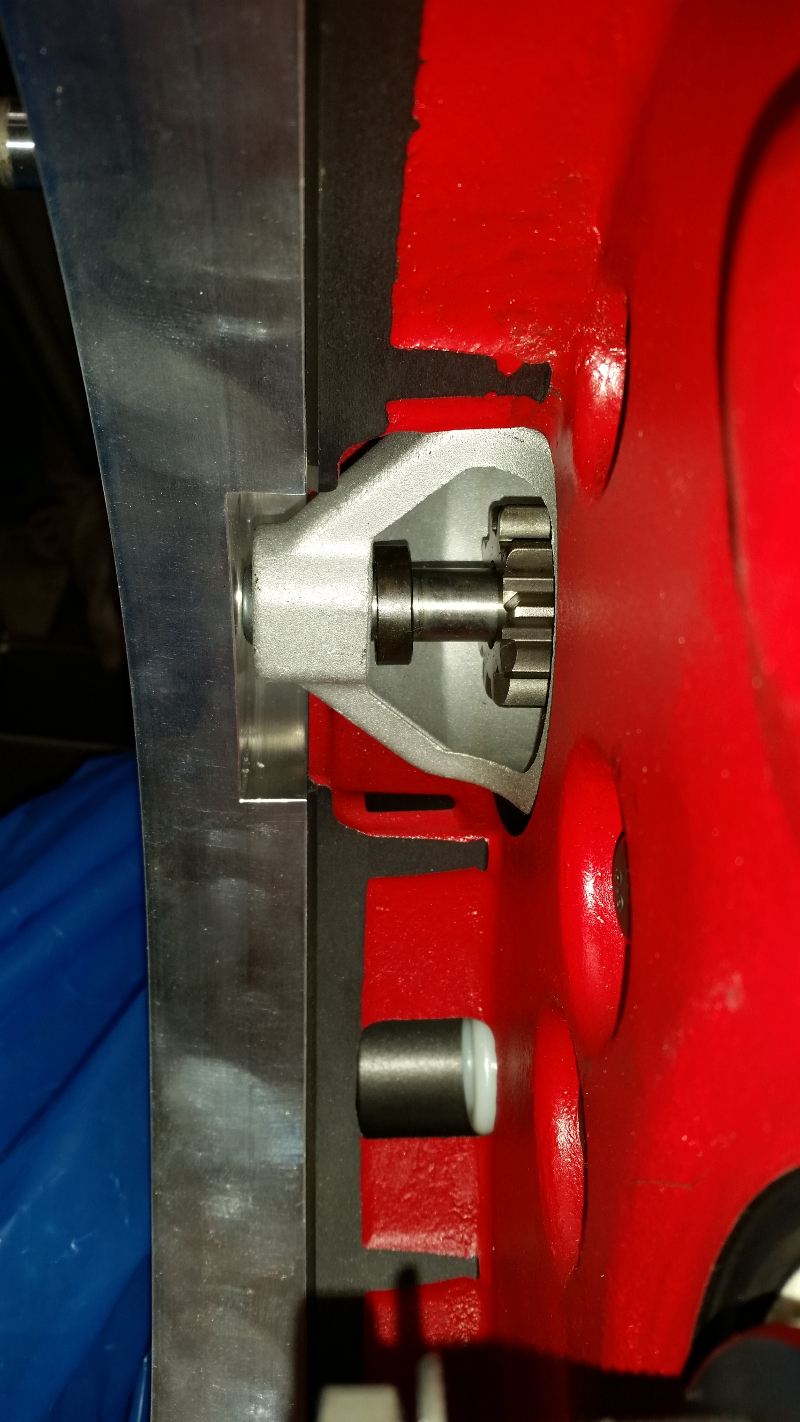

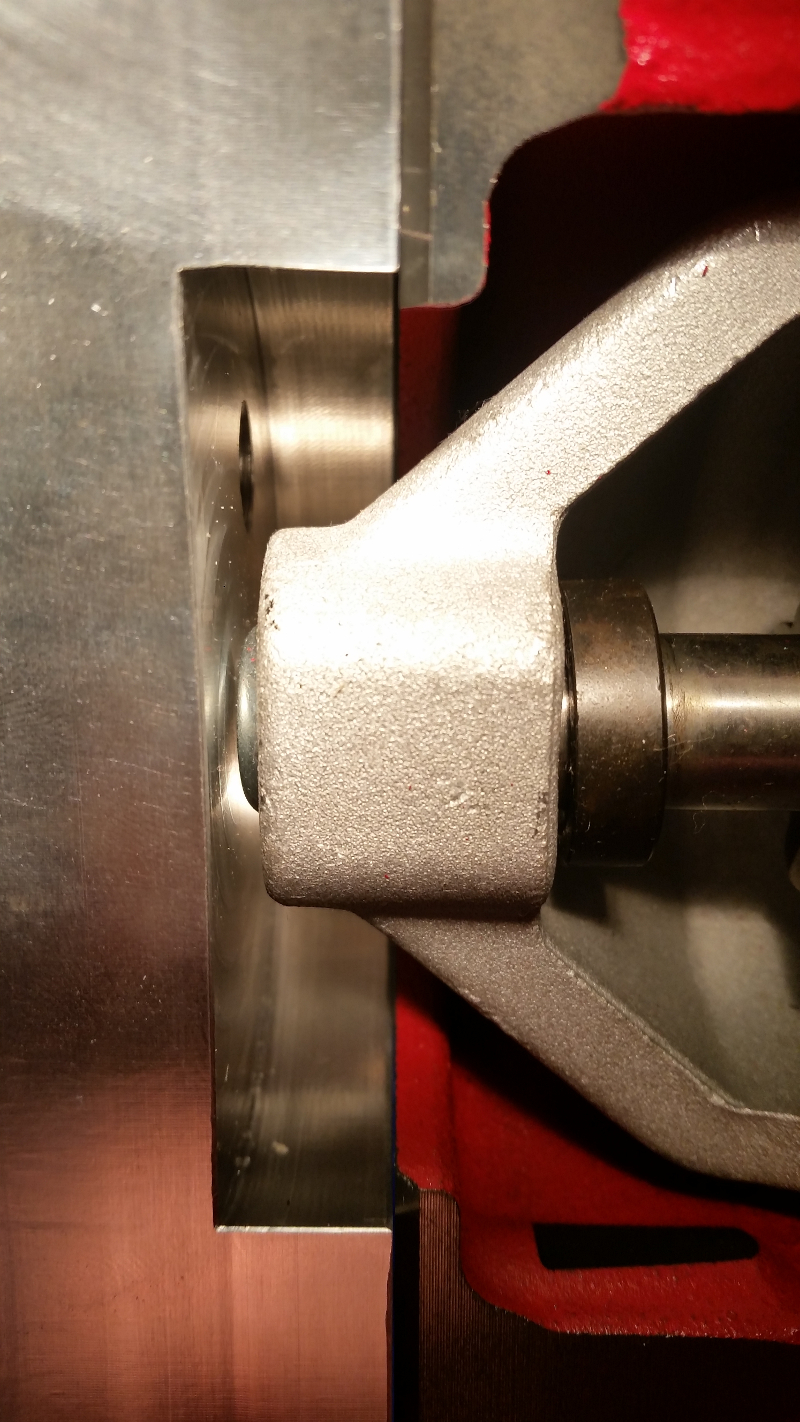

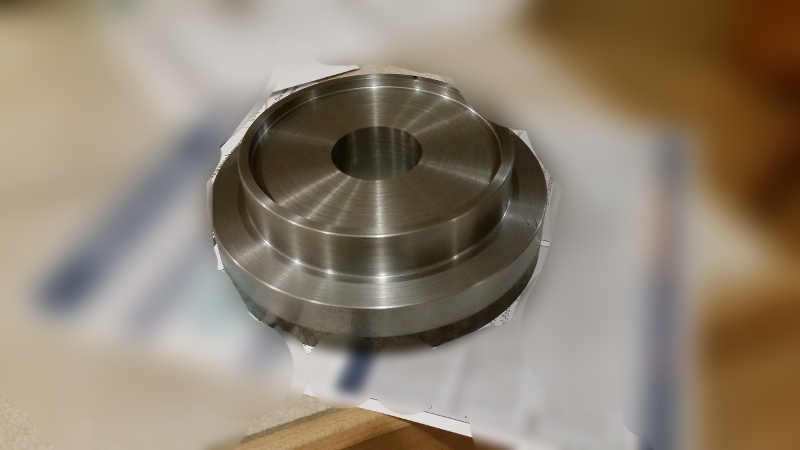

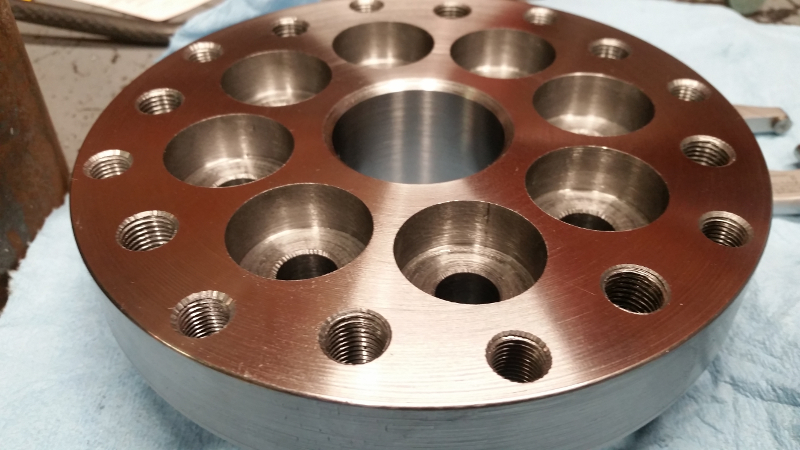

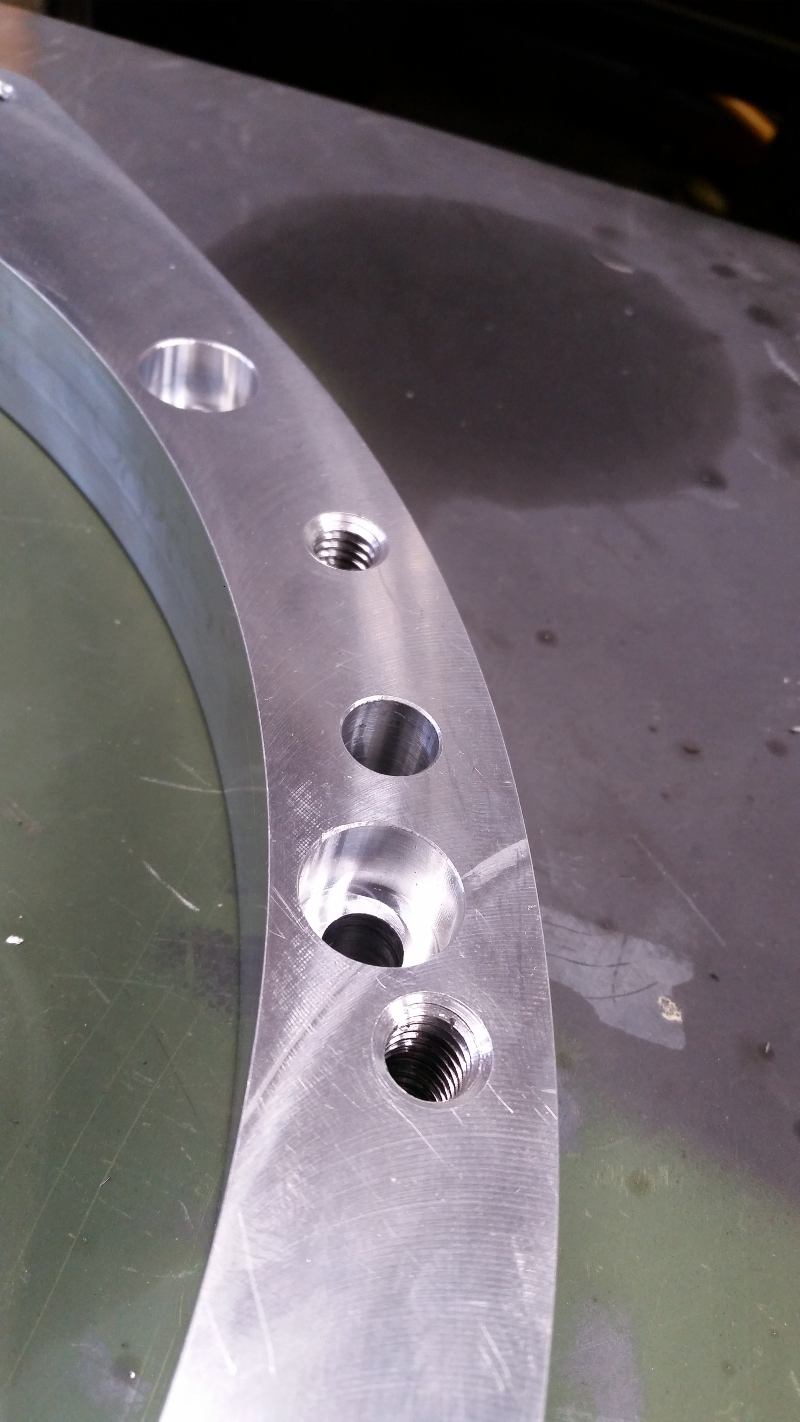

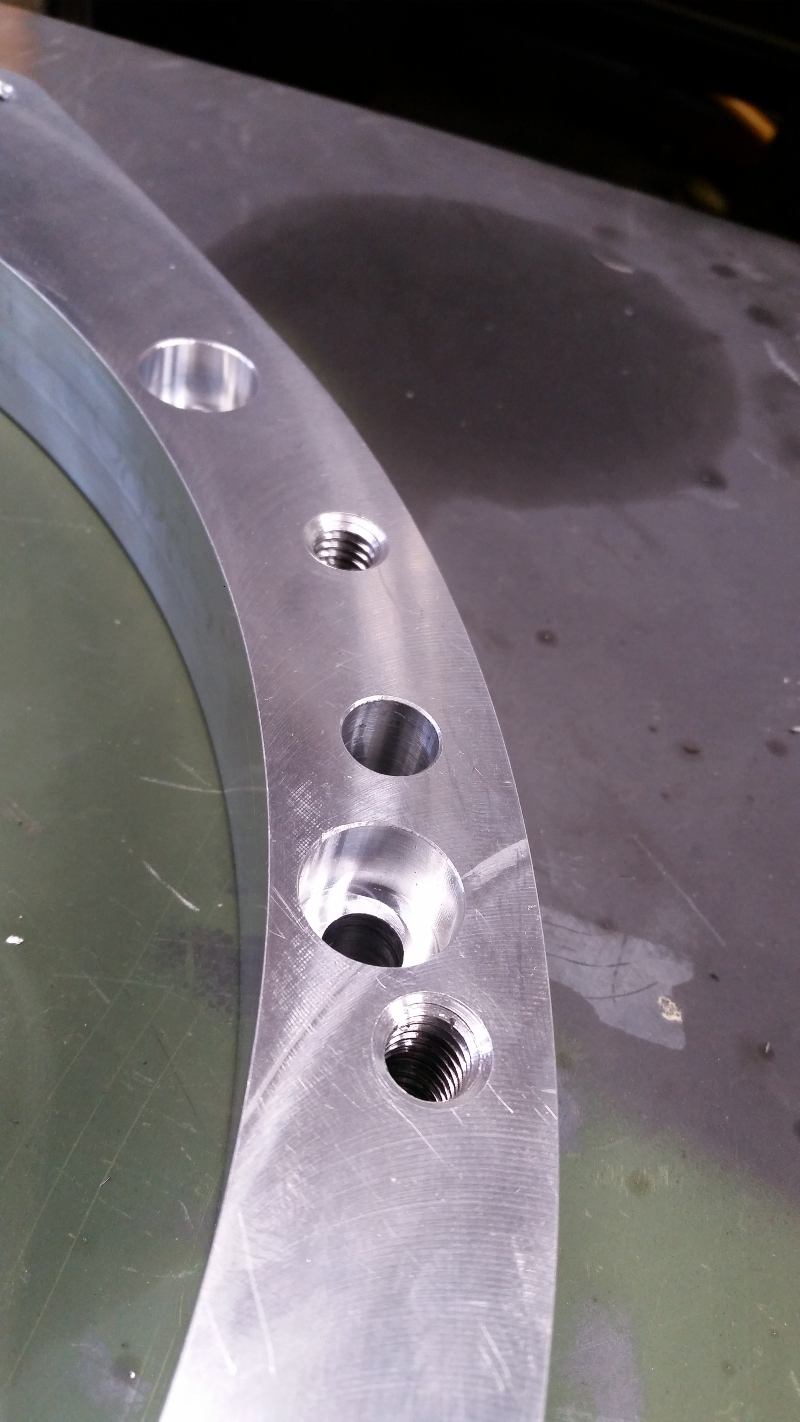

The final product is beautiful and dead accurate. The guys CMMd the part and the critical dowel pins holes were all within 0.0002" of their nominal positions. The dowel holes were reamed, so press fit will be very precise.

I spoke with our manufacturing engineer at work in order to get a recommendation on a machine shop. (our shop is busy most of the time) He looked at my project and thought we could fit it into the schedule, so we had some back and forth discussing how to produce my bell housing adapter, what machine should run it, who would program it and what was critical. I went ahead and purchased the raw material, a 50lb slab of 6061-T651 aluminum plate that measured 18"x18"x1.5"

After about 4 weeks, it was time to run my part. The guys really did a great job. It was run in a horizontal mill with a pallet changer and a 35HP spindle. It made short work of my plate.

The final product is beautiful and dead accurate. The guys CMMd the part and the critical dowel pins holes were all within 0.0002" of their nominal positions. The dowel holes were reamed, so press fit will be very precise.

Last edited: