Griffin shipped me an auto radiator instead of a manual.

So why can't I then use the cooler in the radiator to cool my p/s fluid? Yes, it will raise the temp of my synthetic fluid to 195F but it won't ever get any hotter. It will be SUPER handy not having to mount my little Hayden stacked plate cooler somewhere up front.

Why wouldn't it work just fine?

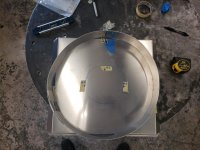

Tubing for mounting fenders and radiator is tacked in place. Bottom mount for the radiator is painted (love to paint cars, hate to paint car parts- just takes too much time).

What brand/type of black industrial type field serviceable hose do you use for power steering? I have been using Ryco Avenger T16 series with field serviceable fittings.

This stuff is rated for backhoe use but I can't find it anywhere on line. Won't use braided SS as it has terrible abrasion resistance compared to the black rubber type hose.

So why can't I then use the cooler in the radiator to cool my p/s fluid? Yes, it will raise the temp of my synthetic fluid to 195F but it won't ever get any hotter. It will be SUPER handy not having to mount my little Hayden stacked plate cooler somewhere up front.

Why wouldn't it work just fine?

Tubing for mounting fenders and radiator is tacked in place. Bottom mount for the radiator is painted (love to paint cars, hate to paint car parts- just takes too much time).

What brand/type of black industrial type field serviceable hose do you use for power steering? I have been using Ryco Avenger T16 series with field serviceable fittings.

This stuff is rated for backhoe use but I can't find it anywhere on line. Won't use braided SS as it has terrible abrasion resistance compared to the black rubber type hose.