Community

Message Forum

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Buy / Sell

Bronco Tech

3 Arm Wiper Setup

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Install the app

-

Welcome to ClassicBroncos! - You are currently viewing the forums as a GUEST. To take advantage of all the site features, please take a moment to register. It's fast, simple and absolutely free. So please join our community today!If you have problems registering or can't log into your account, please contact Admin.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4 link, ORI's, narrowed D60w/only 2.5" lift, 5"+WB stretch, 2" floor lower, P/S....,

- Thread starter nvrstuk

- Start date

She moved!! Not under her own power... well, winching counts right?  Up on the trailer, finish one tricky spot on the exhaust at my friends exhaust shop... then I can hope the 7/8" x 20 TPI Atlas output shaft nuts I ordered from Parts Mike won't do what the 7/8" x 20 locking nuts that I had did...

Up on the trailer, finish one tricky spot on the exhaust at my friends exhaust shop... then I can hope the 7/8" x 20 TPI Atlas output shaft nuts I ordered from Parts Mike won't do what the 7/8" x 20 locking nuts that I had did...

Threaded the nut on by hand over 4 turns. Started turning it with the torque wrench and my shoulder whined (part of the story- not whining about my shoulder! and I got my little 3/8" Milw impact out. Started zipping the nut in the rear output to get it up tight, then grab the torque wrench and be done... Well, the little impact started moaning after about 4 turns... I thought, "what the heck", put it in reverse and it could barely remove the nut... I was thinking NOOOOoooo... not on my bra d new 300M output shaft!!

and I got my little 3/8" Milw impact out. Started zipping the nut in the rear output to get it up tight, then grab the torque wrench and be done... Well, the little impact started moaning after about 4 turns... I thought, "what the heck", put it in reverse and it could barely remove the nut... I was thinking NOOOOoooo... not on my bra d new 300M output shaft!!  Yes, three threads messed up... what happened? Looked at the nut and it looked good enough that you would use it if it came out of your parts bin!! Really!

Yes, three threads messed up... what happened? Looked at the nut and it looked good enough that you would use it if it came out of your parts bin!! Really!

Course nobody in our State has any Atkas tcase nutso I ordered a pair of standard Atlas output shaft nuts. Mine had the small indentation opposite each other on 2 sides which are the self locking part of the nut. It ruined the 3 threads. I spend almost 4 hours working carefully with a small 3 pt (triangular) file and a thread chase tool. Three of the other nuts threads on the frt output shaft tthe exact same number of turns as the rear output shaft. The threads were clean on the shaft AND rhe nut. Just something I check everytime...

So I"m good until I see what the new nuts look like. I was I'll admit ... a bit concerned for a couple hours... can't believe the nut was unscathed by the end of the shaft but it wasn't...

Anyway... whew. Hope I dodged a bullet.

Threaded the nut on by hand over 4 turns. Started turning it with the torque wrench and my shoulder whined (part of the story- not whining about my shoulder!

Course nobody in our State has any Atkas tcase nutso I ordered a pair of standard Atlas output shaft nuts. Mine had the small indentation opposite each other on 2 sides which are the self locking part of the nut. It ruined the 3 threads. I spend almost 4 hours working carefully with a small 3 pt (triangular) file and a thread chase tool. Three of the other nuts threads on the frt output shaft tthe exact same number of turns as the rear output shaft. The threads were clean on the shaft AND rhe nut. Just something I check everytime...

So I"m good until I see what the new nuts look like. I was I'll admit ... a bit concerned for a couple hours... can't believe the nut was unscathed by the end of the shaft but it wasn't...

Anyway... whew. Hope I dodged a bullet.

Attachments

Last edited:

So as I'm trying to get the Bronco "trailer worthy" for a short trip to town I was looking at my brake brackets.. only looking again because I don't like the way they fit- rather, don't fit.

They don't fit down on the axle enough so the top of the pad rides near the top of the rotor as intended. I will show you the pics of why I decided to continue to mod the purchased caliper brackets. If I ground another 1/4"+ out of the caliper bracket so it would sit on the tube properly and allow the disc pad to sit properly there wouldn't be much meat left on the caliper bracket. So I made some small pcs to allow the bracket to be plenty strong, not warp and fit perfect and these pcs go directly below the caliper.

They don't fit down on the axle enough so the top of the pad rides near the top of the rotor as intended. I will show you the pics of why I decided to continue to mod the purchased caliper brackets. If I ground another 1/4"+ out of the caliper bracket so it would sit on the tube properly and allow the disc pad to sit properly there wouldn't be much meat left on the caliper bracket. So I made some small pcs to allow the bracket to be plenty strong, not warp and fit perfect and these pcs go directly below the caliper.

Last edited:

Pics wouldn't load up... here we go...

You can see that ifI took another 1/4" off to slide it down over the tube that wouldnt be much meat left on the bracket...so I added some.

Clamped it down tight to prevent warpage when running about 1 1/2" long bead at a time.

Got the caliper brackets welded on tonight

You can see that ifI took another 1/4" off to slide it down over the tube that wouldnt be much meat left on the bracket...so I added some.

Clamped it down tight to prevent warpage when running about 1 1/2" long bead at a time.

Got the caliper brackets welded on tonight

Attachments

Last edited:

Off to move one pipe 1/2" from the frame rsil... after wrapping tape all around my calipers, hanging them from the frame with ratchet straps and twine...going to the shop before Thursday pm, unloading off the trailer by hand, pushing it on to a hoist by hand we spent a couple hours on it, finished welding up two joints and I took it home and started it... LEAKS at the turbo V clamp now! Ha... maybe I can drive it on to the trailer by Monday...safe a lot of hassle... can't believe I didn't start it before I left...

Wow. Fix it on Monday. He's off to Boise for the drags-literally races dragsters

Fix it on Monday. He's off to Boise for the drags-literally races dragsters

.

Wow.

.

Attachments

BanditBronco

Sr. Member

- Joined

- Jul 2, 2008

- Messages

- 690

I have buddies with buggies that run Werock that really like the RAdesigns stuff. I vote you give that one a shot.

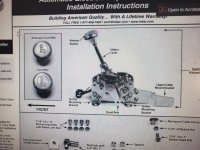

Yeah BanditBronco, Rory put some thought into it for sure. I've run it thru the shift patterns at his shop last winter... extremely versatile shifter.

He used parts of my 6r for mockup and now has my old 4r70 I took out and is using it for shifter mockup. Good guy

I am using his bumpshift switches in my Winters

He used parts of my 6r for mockup and now has my old 4r70 I took out and is using it for shifter mockup. Good guy

I am using his bumpshift switches in my Winters

Last edited:

Interesting axle lengths...

So 1 1/4' of spline engagement for my engine/trans/wheeling style seems OK to me. My 9" Ford rear ends only had an inch or so of engagement.

I'm cutting axles down now so I'll have spares. You can see in the pic the difference btw the spline engagement. The grease line shows how far the splines are engaged on the two axles- pass side.

DS both have 1 1/2" after cutting.

So 1 1/4' of spline engagement for my engine/trans/wheeling style seems OK to me. My 9" Ford rear ends only had an inch or so of engagement.

I'm cutting axles down now so I'll have spares. You can see in the pic the difference btw the spline engagement. The grease line shows how far the splines are engaged on the two axles- pass side.

DS both have 1 1/2" after cutting.

Attachments

Last edited:

You’ll be good

Agreed. If I go thru 2 sets of stock 14 bolt shafts it's time to go 300M again.

Good news, new nuts from Parts Mike for the output shafts came in and lo and behold they fit like the other ones should have!

I am guessing that the interference fit of the self locking nut was machined improperly and that's why it peeled the threads off my 300 M shaft.

Good news is it works...

Good news, new nuts from Parts Mike for the output shafts came in and lo and behold they fit like the other ones should have!

I am guessing that the interference fit of the self locking nut was machined improperly and that's why it peeled the threads off my 300 M shaft.

Good news is it works...

Agreed. If I go thru 2 sets of stock 14 bolt shafts it's time to go 300M again.

Good news, new nuts from Parts Mike for the output shafts came in and lo and behold they fit like the other ones I got from Advance Adapters should have!

I am guessing that the interference fit of the self locking nut was machined improperly and that's why it peeled the threads off my brand new300 M shaft.

Good news is it works...

Good news, new nuts from Parts Mike for the output shafts came in and lo and behold they fit like the other ones I got from Advance Adapters should have!

I am guessing that the interference fit of the self locking nut was machined improperly and that's why it peeled the threads off my brand new300 M shaft.

Good news is it works...

Attachments

Last edited:

Got most of the day in the shop... Calipers are welded up tight, flanges on both ends of the ProCase, frt D60 yoke changed out to forged 1350, made some funky little brackets to hold my shift linkage which on the 6r80 has to come under the Atlas... IF I keep the Winters I will incorporate a full belly plate that will completely cover the Atlas like my last couple skid plates but I will extend to give my trans pan some protection also... otherwise I have found that the Lokar shift linkage for some reason is shorter and can be mounted one set of bolts farther forward on the trans pan and the cable can go ABOVE the Atlas... huge benefit to that. We will see how this works first...

Speedo is in the Atlas. Found a local cable that should be long enough from dash to Atlas. No doubler so a 93" one isn't needed anymore. Torqued a bunch of bolts carefully today.

Have a punchlist of 1-12 things for tomorrow that if all I had to do were 1-11 I'd be test driving tomorrow. I have to fit and weld in my "mini"-truss I call it. Sch 40 pipe sliced lengthwise, welded to my truss to give the axle tubes double the beef they have now.

Pics tomorrow.

Speedo is in the Atlas. Found a local cable that should be long enough from dash to Atlas. No doubler so a 93" one isn't needed anymore. Torqued a bunch of bolts carefully today.

Have a punchlist of 1-12 things for tomorrow that if all I had to do were 1-11 I'd be test driving tomorrow. I have to fit and weld in my "mini"-truss I call it. Sch 40 pipe sliced lengthwise, welded to my truss to give the axle tubes double the beef they have now.

Pics tomorrow.

Mini truss made of Sch 40 pipe is done.... wow, BEEF. Looks so simple, no "glitz" like all the typical 8" tall trusses you see.

Benefit of the split pipe laid over my axle tube is it allowing snow and sand to flow between the housing, the tank and body... won't be a big ugly plow or anchor back there.

Spent the day wrapping up my 12 steps on my punch list (that really is closer to 15) but I'm down to:

-putting the caliper and pins on

- silicone the 13 bolt cover on

- make new "full floater" ends so if I waste an axle I can put a cap on the axle end and drive home in 3x4 or if the rear is wasted I can pull both sides and use FWD like I have the last 11 months.

- fill the rear diff

- Start it up- run it thru the gears see if the controller and trans works. Top off the trans when it gets hot (if it will).

- Driveshafts in

- Tires on

- Axles in

Hope it all works!

Here's a couple pics during the process.

Whoops, slipped in another axle cutting pic by accident.

Benefit of the split pipe laid over my axle tube is it allowing snow and sand to flow between the housing, the tank and body... won't be a big ugly plow or anchor back there.

Spent the day wrapping up my 12 steps on my punch list (that really is closer to 15) but I'm down to:

-putting the caliper and pins on

- silicone the 13 bolt cover on

- make new "full floater" ends so if I waste an axle I can put a cap on the axle end and drive home in 3x4 or if the rear is wasted I can pull both sides and use FWD like I have the last 11 months.

- fill the rear diff

- Start it up- run it thru the gears see if the controller and trans works. Top off the trans when it gets hot (if it will).

- Driveshafts in

- Tires on

- Axles in

Hope it all works!

Here's a couple pics during the process.

Whoops, slipped in another axle cutting pic by accident.

Attachments

Last edited:

Got the speedo hooked up. Why can't Advance Adapters put some instructions in with their $2300-3500 t-cases? One slip of paper would be nice. Especially since their website was down and the only tech help you could get was "COVID-19" information... lol

No info on how the speedo should be rotated as the ProCase does not have an indent, no marks on the Pro-Case, etc. oh well...

Got the brgs cleaned up, seals installed. So remember I had to put spacers in behind the inner race so this moves the seal out some so in order for it to actually rotate on the seal surface on the spindle I had to have it stick out from the hub .150". This puts the seal lip almost in the center of the seal surface on the spindle... will see how it does. I am within about .010" around the perimeter of the seal so it sticks out about as even as possible.

No info on how the speedo should be rotated as the ProCase does not have an indent, no marks on the Pro-Case, etc. oh well...

Got the brgs cleaned up, seals installed. So remember I had to put spacers in behind the inner race so this moves the seal out some so in order for it to actually rotate on the seal surface on the spindle I had to have it stick out from the hub .150". This puts the seal lip almost in the center of the seal surface on the spindle... will see how it does. I am within about .010" around the perimeter of the seal so it sticks out about as even as possible.

Attachments

Last edited:

JSmall

Bronco Guru

- Joined

- Feb 18, 2004

- Messages

- 3,224

Mini truss made of Sch 40 pipe is done.... wow, BEEF. Looks so simple, no "glitz" like all the typical 8" tall trusses you see.

Benefit of the split pipe laid over my axle tube is it allowing snow and sand to flow between the housing, the tank and body... won't be a big ugly plow or anchor back there.

Exactly why I chose a smaller truss this time around

Everything is looking good

JS- you will love the "no worry" about having the extra beef of tbe 14 bolt.

[/RIGHT]OTE=JSmall;3308333]Exactly why I chose a smaller truss this time around I don't want the truss to limit my up travel like the one I have on my 9 inch.

I don't want the truss to limit my up travel like the one I have on my 9 inch.

Everything is looking good[/QUOTE]

[/RIGHT]OTE=JSmall;3308333]Exactly why I chose a smaller truss this time around

Everything is looking good[/QUOTE]

Sorry this is going soooo slow but I'm making progress anyway!

She RUNS!!!!

6r80 TRANNY SHIFTS

NO FUNKY NOISES!!

Still working on moving an exhaust pipe half an inch... 3 hours today, will finish in the am...

She RUNS!!!!

6r80 TRANNY SHIFTS

NO FUNKY NOISES!!

Still working on moving an exhaust pipe half an inch... 3 hours today, will finish in the am...

I'll post up a few random pics from the past couple days..

One thing I've really already noticed in the 1500 ft I've driven it... 4.17 first gear and the converter is much tighter than my 2200 billet one in my 4r70.

Atlas product info is worse than terrible. Nonexistant and their website doesn't have the info EVEN when it is working!

Speedo housing on the RaceCase model doesn't have any markings on it to help you align the speedo gear in the housing... have to call a friend to see how you rotate it so it will mesh properly with the gears.

I updated from the locking tabs to the newer style keyway and lockring.

One thing I've really already noticed in the 1500 ft I've driven it... 4.17 first gear and the converter is much tighter than my 2200 billet one in my 4r70.

Atlas product info is worse than terrible. Nonexistant and their website doesn't have the info EVEN when it is working!

Speedo housing on the RaceCase model doesn't have any markings on it to help you align the speedo gear in the housing... have to call a friend to see how you rotate it so it will mesh properly with the gears.

I updated from the locking tabs to the newer style keyway and lockring.

Attachments

Last edited:

Similar threads

- Replies

- 74

- Views

- 18K

- Replies

- 26

- Views

- 455